Bag feeding and edge stamping combined device of automatic packing machine

An automatic packaging machine, packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problem of difficult to implement packaging solutions, and achieve the effect of reliable folding and smooth filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

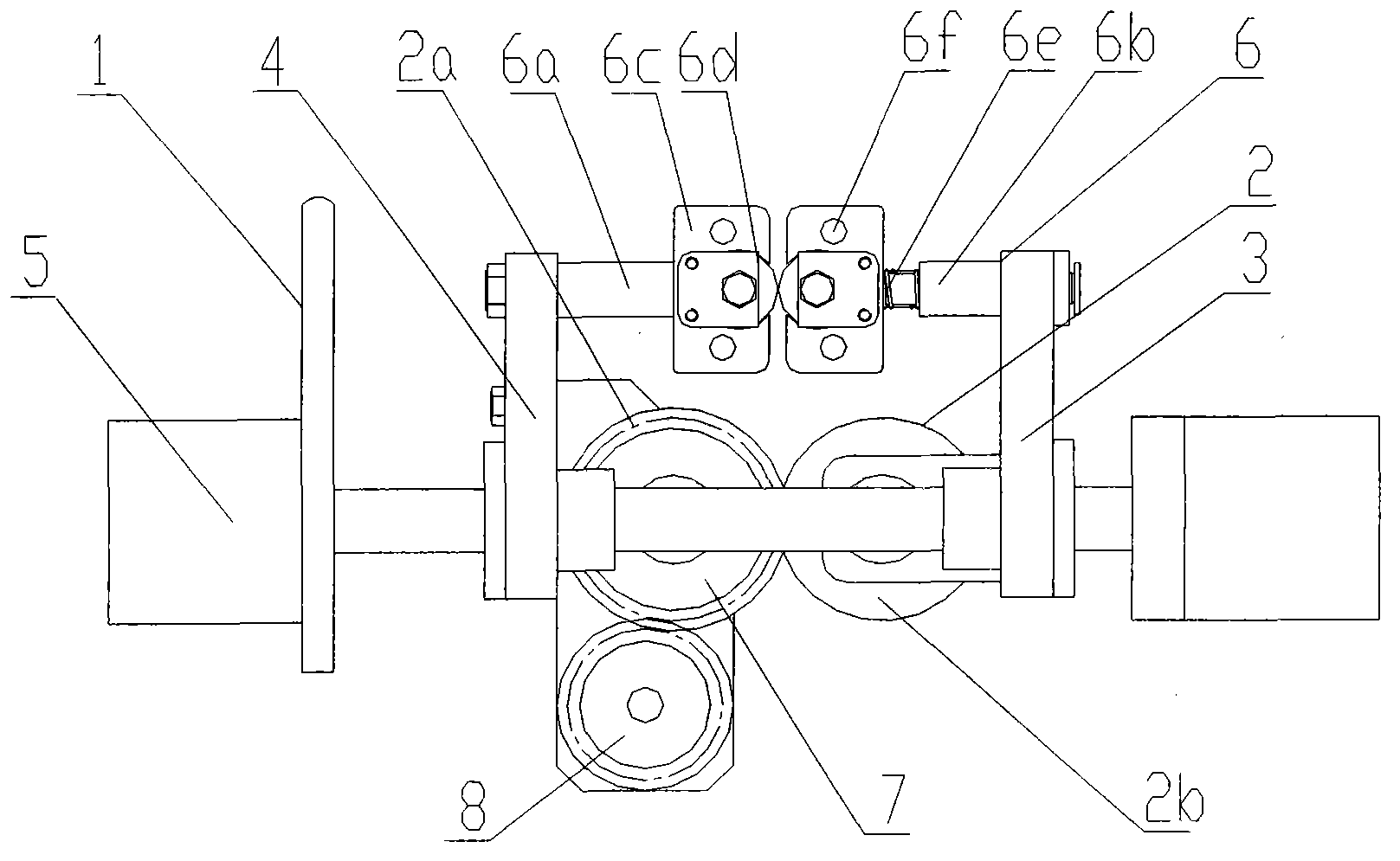

[0011] See figure 1 , The present invention provides a composite bag-feeding and edge-pressing device for an automatic packaging machine, which is installed at the unloading port of the packaging machine and includes a frame 1, which is provided with a bag-feeding device for vertically conveying the packaging bag tube Device 2, the bag-feeding device 2 includes a driving roller 2a and a driven roller 2b disposed oppositely, and a front push plate 3 and a rear push plate 4 are respectively symmetrically provided outside the driving roller 2a and the driven roller 2b, and the front push plate 3 and the rear push plate 4 are respectively provided with a pressing cylinder 5, the piston rod of the pressing cylinder 5 is hinged to the front push plate 3 and the rear push plate 4, pushing the driving roller 2a and the driven roller 2b to reciprocate; An edge ironing device 6 is provided between the top end of the front push plate 3 and the rear push plate 4, and the edge ironing devic...

Embodiment 2

[0013] The power system of the driving roller 2a in the bag feeding device 2 can be completed by gear transmission. A driven gear 7 is arranged outside the driving roller 2a, and the driving gear 8 meshes with it, and the driving gear 8 is driven by the motor to complete the power transmission. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com