Surface gluing device for tape production

A gluing device and adhesive tape technology, which is applied to the device for coating liquid on the surface, the mixer with a rotating stirring device, coating, etc., which can solve the problems of inconvenient tape rewinding, inconvenient tape wiping, and surface damage of the tape, etc. problems, to achieve the effect of avoiding uneven gluing, improving portability, and ensuring long progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

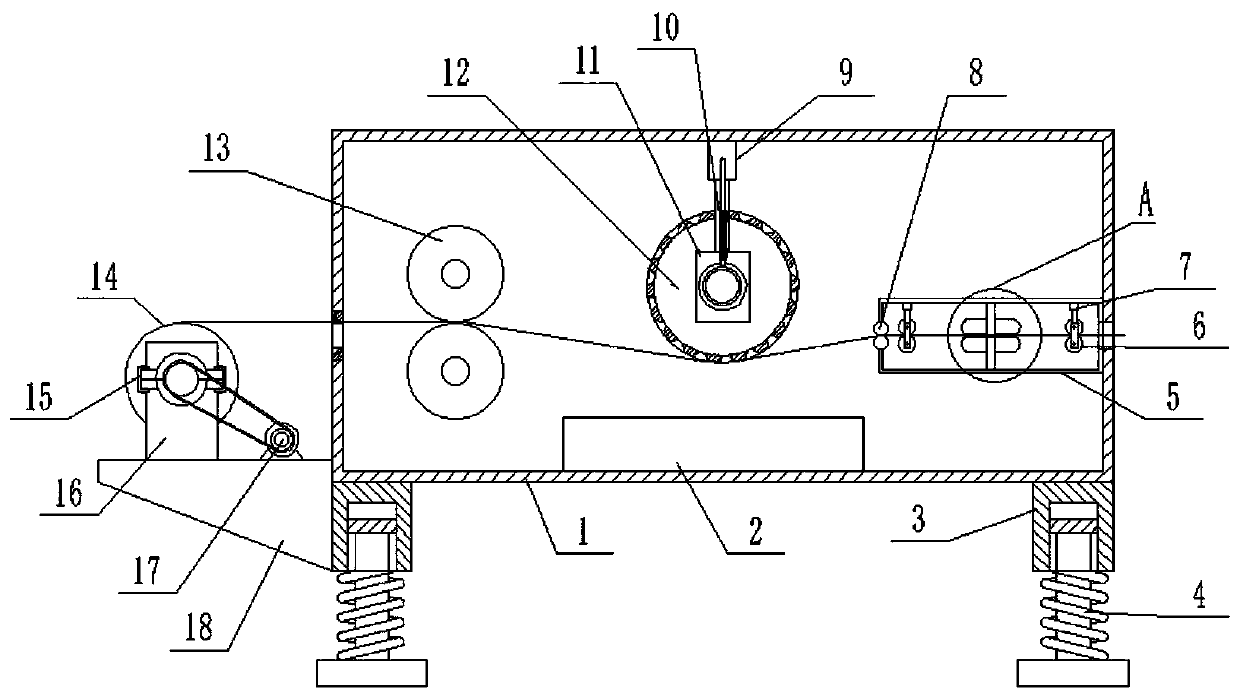

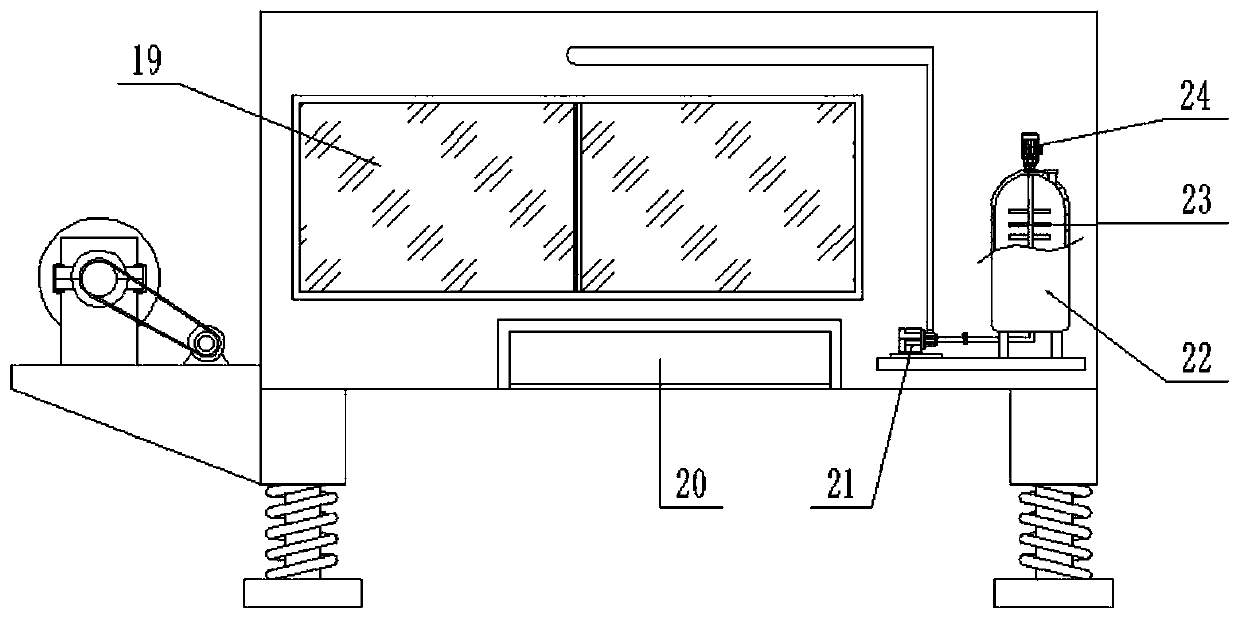

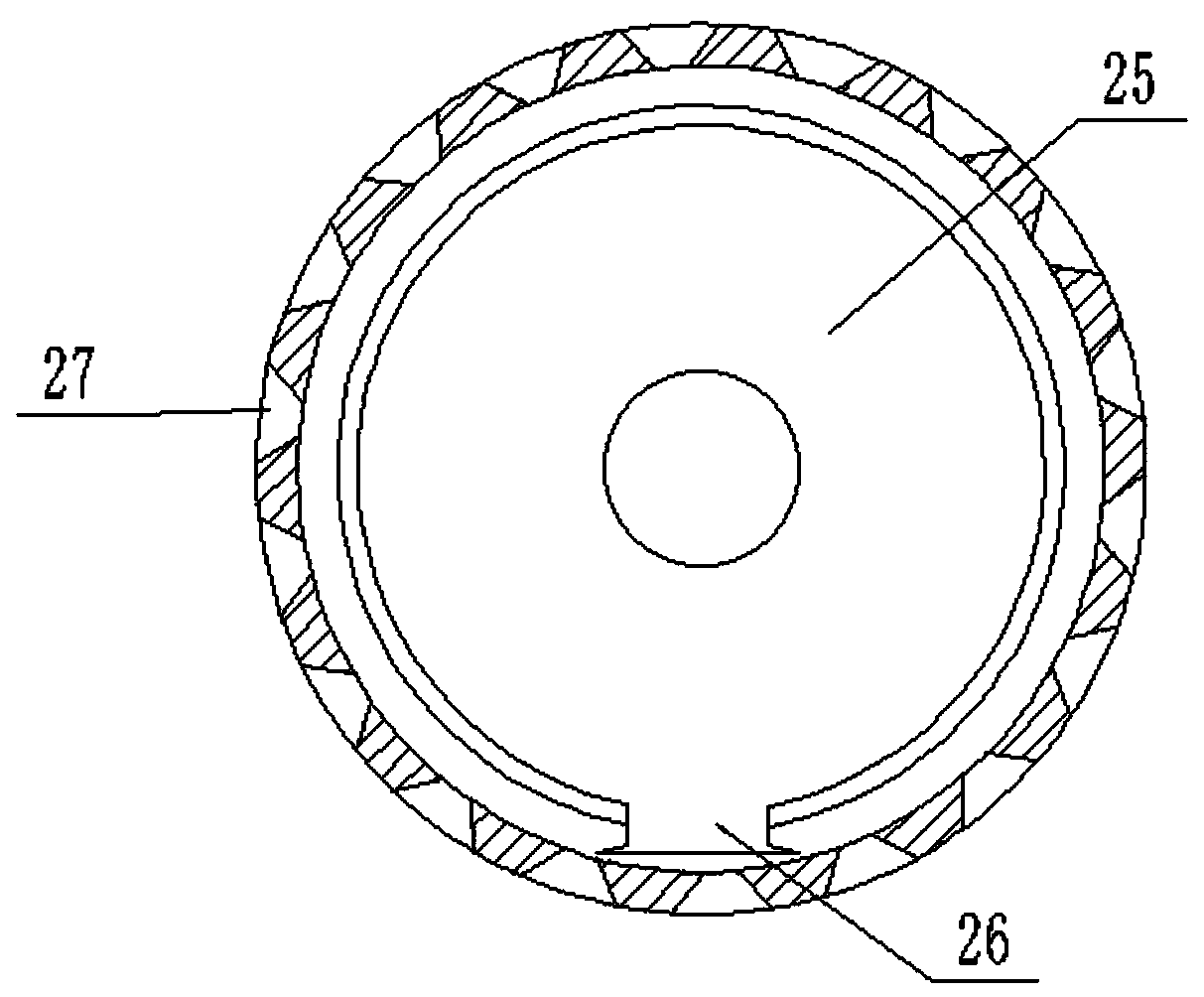

[0026] refer to Figure 1-5 , a surface gluing device for adhesive tape production, comprising a box body 1, a glue storage tank 22 and a fixed table 18 welded to the side wall of the box body 1, the top of the fixed table 18 is fixed with a winding device by bolts, and the bottom of the box body 1 The four corners of the outer wall are welded with a buffer seat 3, and the inner wall of one side of the box body 1 is welded with a dust removal box 5, and both sides of the inner wall of the top of the dust removal box 5 are fixed with a wiping protection mechanism by screws, and the central axis of the inner wall of the dust removal box 5 top There is a wiping mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com