Method for operating vacuum pump system

A vacuum pump, vacuuming technology, applied in the direction of pump, pump parameters, piston pump, etc., can solve the problems of time conflict, high noise and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

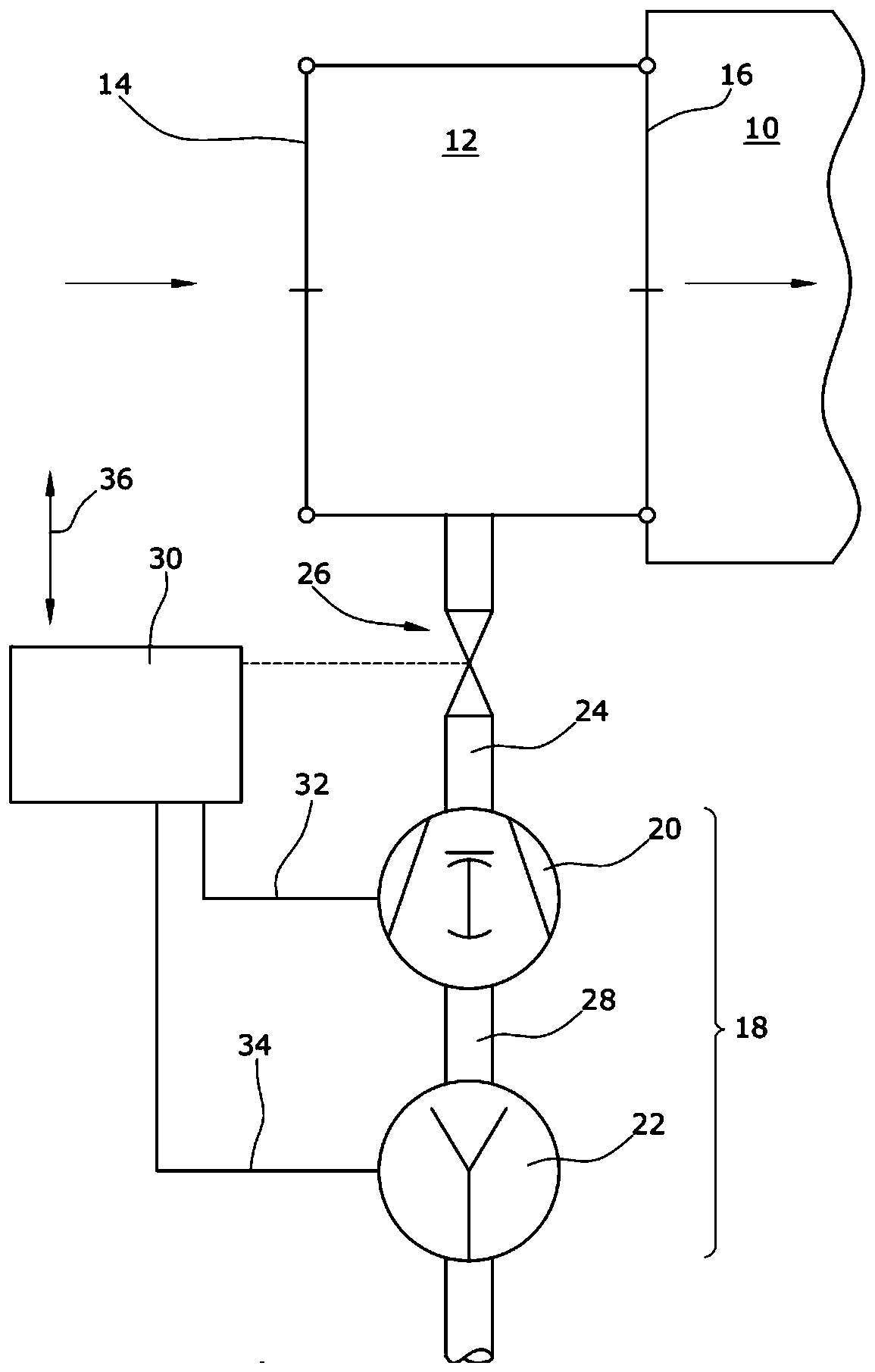

[0035] In the schematically depicted treatment chamber 10 the product is treated, for example coated. To this end, a vacuum is generated in the processing chamber 10 . A lock chamber 12 is connected to the processing chamber 10 for feeding products, materials etc. to be processed into the processing chamber. The lock chamber 12 includes a lock inlet 14 for feeding product or the like into the lock chamber 12 and a lock outlet 16 for transferring the product or the like from the lock chamber 12 into the processing chamber 10 .

[0036] In order to evacuate the lock chamber 12, the lock chamber 12 is connected to a vacuum pump system. The vacuum pump system includes a vacuum pump device 18 . In the illustrated exemplary embodiment, the vacuum pump arrangement 18 includes a main vacuum pump 20 and a pre-vacuum pump 22 arranged in series downstream of the main vacuum pump 20 . The main vacuum pump 20 is in particular a Roots pump or a screw pump. The main vacuum pump 20 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com