Sliding-in type fixing structure of rigid plates

A technology for fixing structures and rigid plates, applied in the direction of thin plate connections, connecting components, mechanical equipment, etc., can solve problems such as breakage and bolt bending, and achieve the effects of easy operation, reduced friction, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

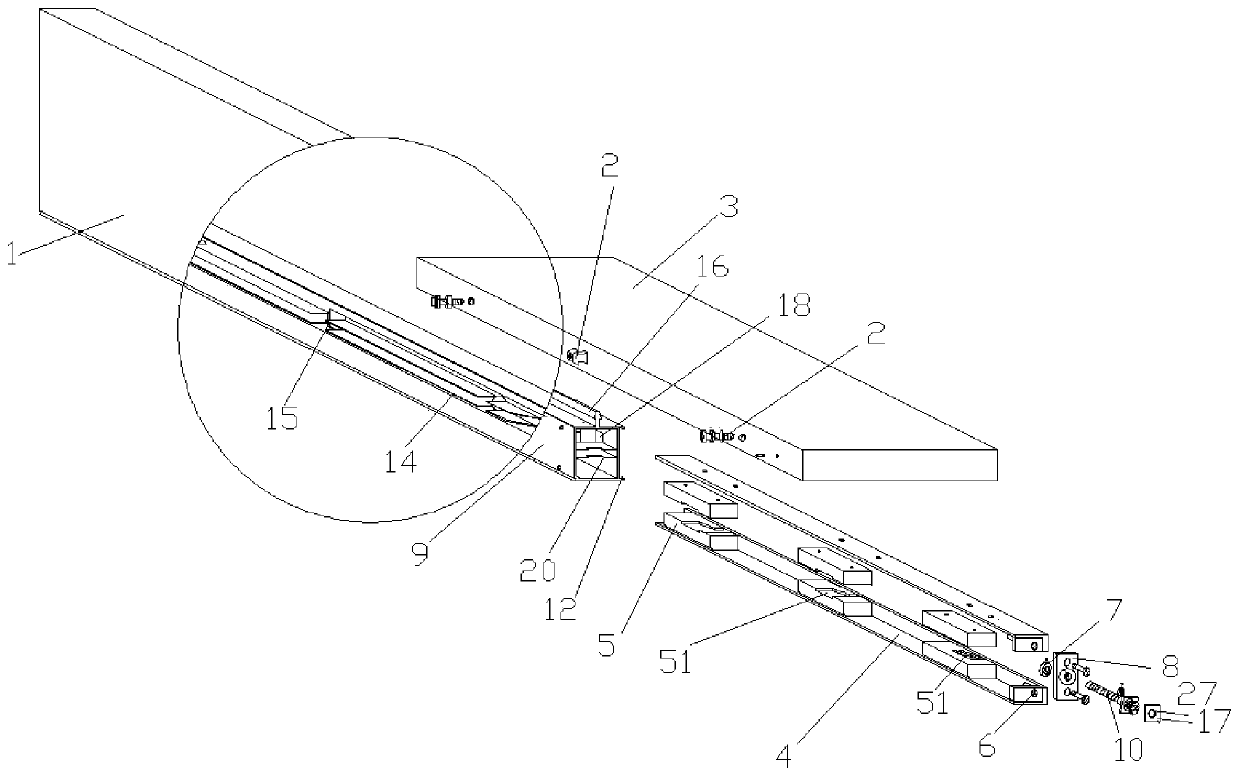

[0035] like Figure 1-9 As shown, the embodiment of the present invention provides a fixing structure for a slide-in rigid plate body, including: a fixing part 2, which is arranged in the first rigid plate body 3 to be connected; at least one set of Body 3 and the clamping member 5 arranged opposite to the connection direction of the second rigid plate body 1, the clamping member 5 is arranged in the second rigid plate body 1 to be connected, the movement direction of the clamping member 5 is in line with the The connection direction of the first rigid board 3 and the second rigid board 1 intersects, and grooves are provided on the opposite surfaces of the two clamping parts 5 to allow the fixing part 2 to slide in laterally. 51, the bottom wall of the groove body 51 is set on a slope, so that when the clamping member 5 moves, it drives the fixing member 2 to slide from low to high along the slope, and the first rigid plate body 3 and the second rigid plate body 1 apply a for...

Embodiment 2

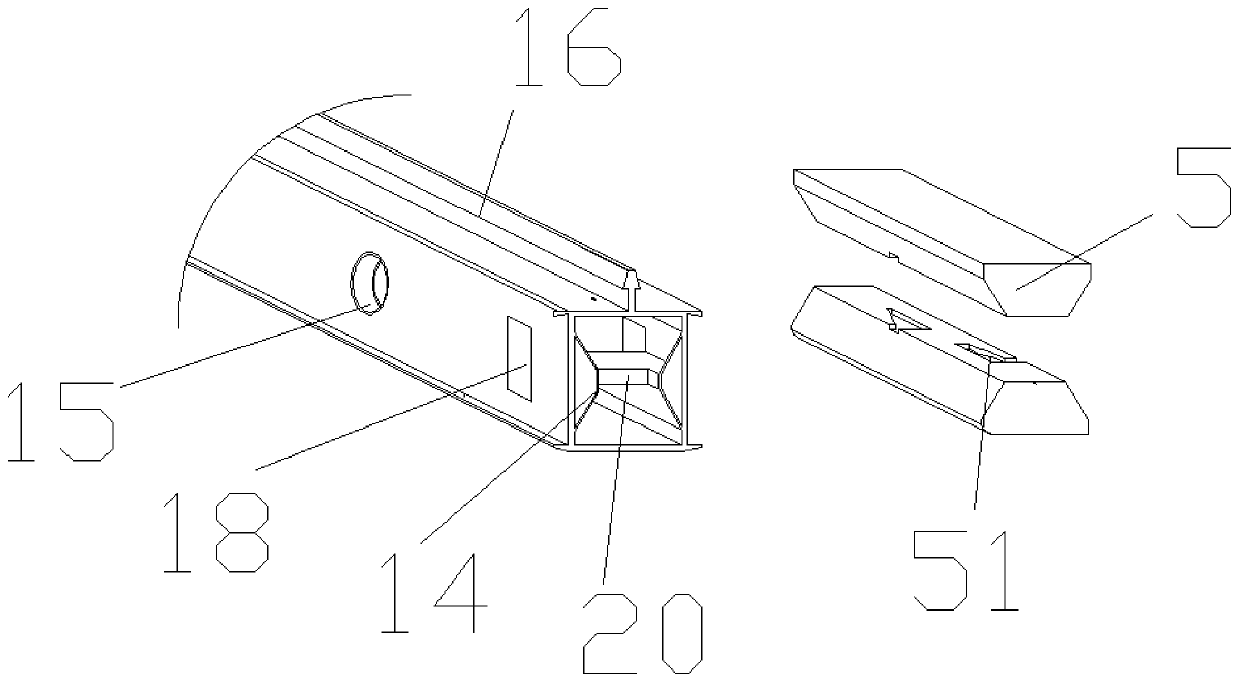

[0056] like Image 6 As shown, the longitudinal section of the clamping member 5 is "U"-shaped, including a first plate body 52, a second plate body 53 and a third plate body 54 connected in sequence, and the groove body 51 is formed on the first plate body. On the side walls of the three boards 54 , the edge of the third board 54 is formed with a riser 55 that allows the fixing member 2 to slide along with the movement of the third board 54 . Other structures are the same as in Embodiment 1.

[0057] The clamping member 5 is integrally formed, and the first plate body 52, the second plate body 53 and the third plate body 54 are sequentially connected into a "U"-shaped structure, and the groove body 51 is formed on the side wall of the third plate body 54. The semicircular opening, and the rising part 55 that is adjacent to the semicircular opening. In this embodiment, the two clamping parts 5 are symmetrically arranged, and the groove body 51 is surrounded into a circular op...

Embodiment 3

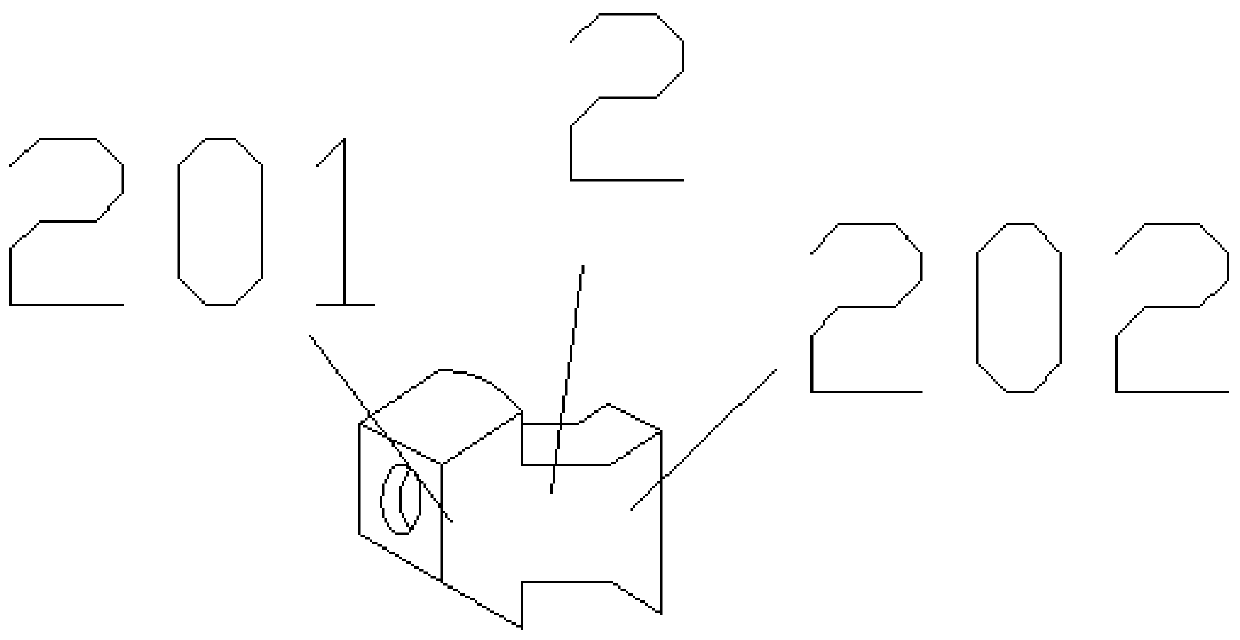

[0061] like Figure 7 As shown, a sliding piece 21 is provided on the side wall of the clamping piece 5 to reduce the frictional force when it slides into the second rigid plate body 1, and the sliding piece 21 is connected to the second rigid plate body. The groove 22 on the inner wall of the body 1 is suitable. Other structures are the same as in Embodiment 1.

[0062] In this embodiment, the fixing part 8 is directly connected to the clamping part 5, the connecting plate 4 is omitted, and the groove body 51 is formed on the clamping part 5 at predetermined intervals. The cross section of the clamping part 5 is elliptical. A plurality of sliding parts 21 are arranged at predetermined intervals on the side wall of the connecting part 5, and grooves 22 adapted to the sliding parts 21 are formed on the side wall of the pipe body 9, which mainly plays a role in reducing the clamping part 5 in the pipe body. 9 The internal sliding friction makes the operation more labor-saving....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com