Assembly type soft steel-friction composite displacement type damper and assembly method thereof

A prefabricated, damper technology, applied in the direction of building types, protected buildings/shelters, building components, etc., can solve the problems of single energy consumption mechanism, residual deformation, complicated replacement, etc., and achieve strong practicability and energy consumption. Good performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with the drawings and embodiments. Obviously, the drawings listed below are only some specific embodiments of the present invention.

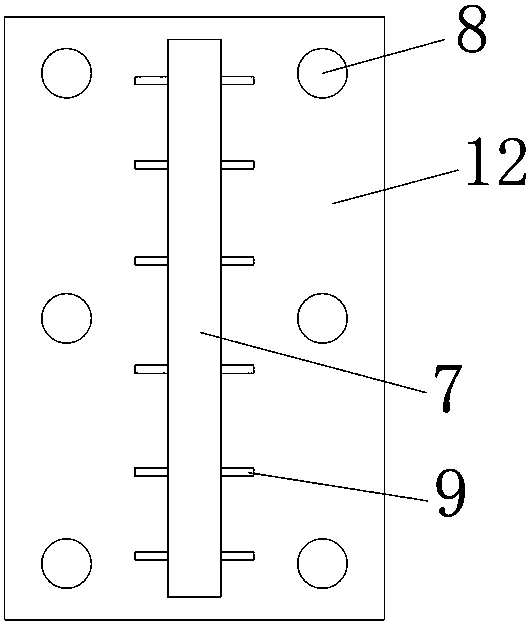

[0038] In terms of direction description, the top plate 1 side is the upper side, the bottom plate 2 side is the lower side, and the two sides of the two friction plates 3 in the coaxial position are the front side and the rear side respectively.

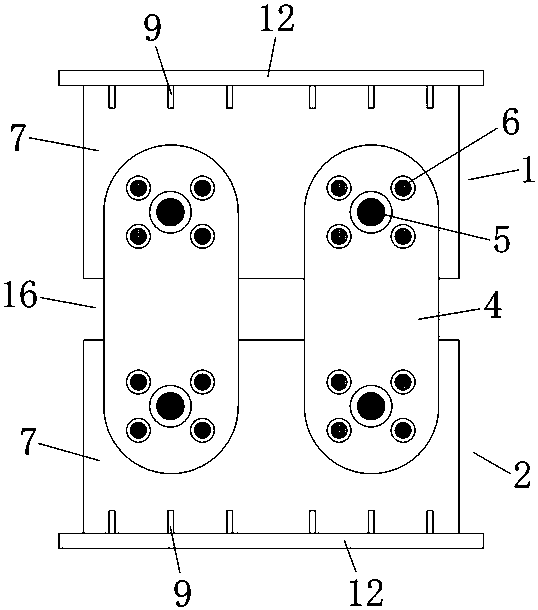

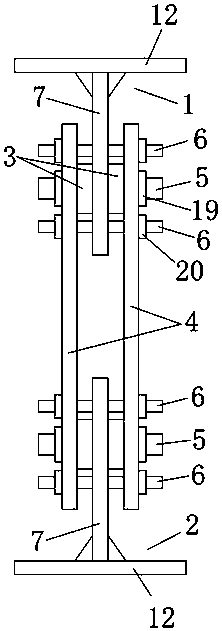

[0039] Such as Figure 1-8 As shown, an assembled mild steel-friction compound displacement damper of the present invention includes a top plate 1 and a bottom plate 2 that are T-shaped and arranged facing each other up and down. The structure and size of the top plate 1 and the bottom plate 2 are the same, and their Both include a horizontally arranged flange plate 12 and a web 7 vertically connected to the middle of the flange plate 12, the flange plate 12 is used to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com