Method for cyclic plating of hydrophobic membranes through plasma chemical vapor deposition

A technology of chemical vapor deposition and plasma gas, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of unproposed combination of multi-layer films, insufficient comprehensive performance of hydrophobic films, and undisclosed multi-layer films Methods and other issues, to achieve good adhesion and bonding effect, ensure durability, and stable film quality

Pending Publication Date: 2019-07-19

FOSHAN SPRING TECH CO LTD

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This coating process can form a single-layer hydrophobic film with a certain thickness, but the comprehensive performance of this single-layer hydrophobic film is not high enough, and there are problems of easy falling off and poor durability.

[0003] At present, there are also records of plasma chemically enhanced vapor depositio

Method used

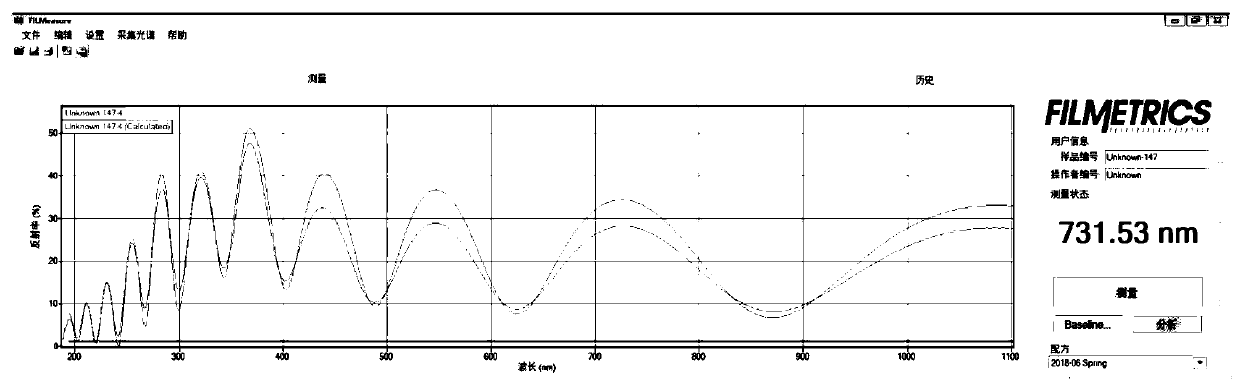

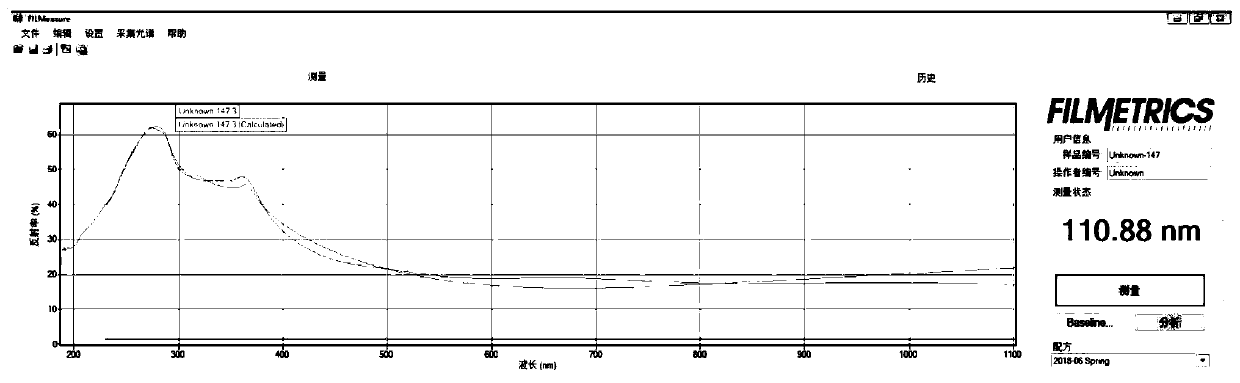

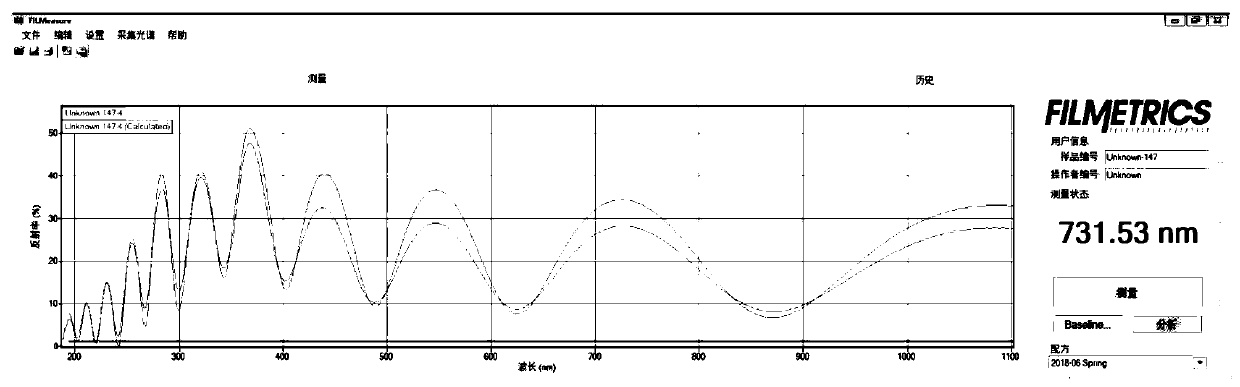

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a method for cyclic plating of hydrophobic membranes through plasma chemical vapor deposition. The method for cyclic plating of the hydrophobic membranes through plasma chemical vapor deposition comprises the following steps of (1) pretreatment is carried out, specifically, a to-be-coated surface is pretreated; (2) activation is carried out, specifically, the to-be-coated surface is activated in a reaction cavity by means of plasma gas; (3) membrane plating is carried out, specifically, a vaporized hydrophobic material enters the reaction cavity, and a hydrophobic membrane is formed by the hydrophobic material on the to-be-coated surface through plasma chemically-enhanced vapor deposition method; (4) feed of the hydrophobic material is stopped, step (2) and step (3)are carried out again, and another hydrophobic membrane is deposited on the original hydrophobic membrane; (5) step (4) is repeated; and (6) vacuum breaking is carried out in the reaction cavity, sothat a workpiece provided with multiple hydrophobic membranes is obtained. According to the method, the multiple hydrophobic membranes are deposited by means of cyclic plating, so that effective adhesion and close stacking of the membranes are facilitated, the quality of the membranes is improved, the membranes can adhere to and be deposited on the surface of the base material more firmly, and thedurability of the hydrophobic property is ensured.

Description

technical field [0001] The invention relates to the technical field of plasma chemically enhanced vapor deposition coating, in particular to a method for circulating a hydrophobic film by plasma chemical vapor deposition. Background technique [0002] In the plasma chemically enhanced vapor deposition coating process, especially in the hydrophobic film coating process, the collision reaction between the plasma gas carrier gas and the vaporized hydrophobic material is maintained for a period of time, and a layer of hydrophobic film is formed on the surface of the workpiece. According to the thickness requirements of the hydrophobic film, control The length of the reaction time. This coating process can form a single-layer hydrophobic film with a certain thickness, but the comprehensive performance of this single-layer hydrophobic film is not high enough, and there are problems of easy peeling and poor durability. [0003] At present, there are also records of plasma chemical...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C23C16/513C23C16/02

CPCC23C16/0245C23C16/513

Inventor 吕伟桃王宪梁宸

Owner FOSHAN SPRING TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap