Complex enzyme fermenting system for solid state fermentation high activity feed

A feed compound enzyme and fermentation system technology, which is applied in the field of solid-state fermentation with high activity feed compound enzyme fermentation system, can solve the problems of large influence on quality, large difference between compound enzyme temperature and surface temperature, poor quality of compound enzyme, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

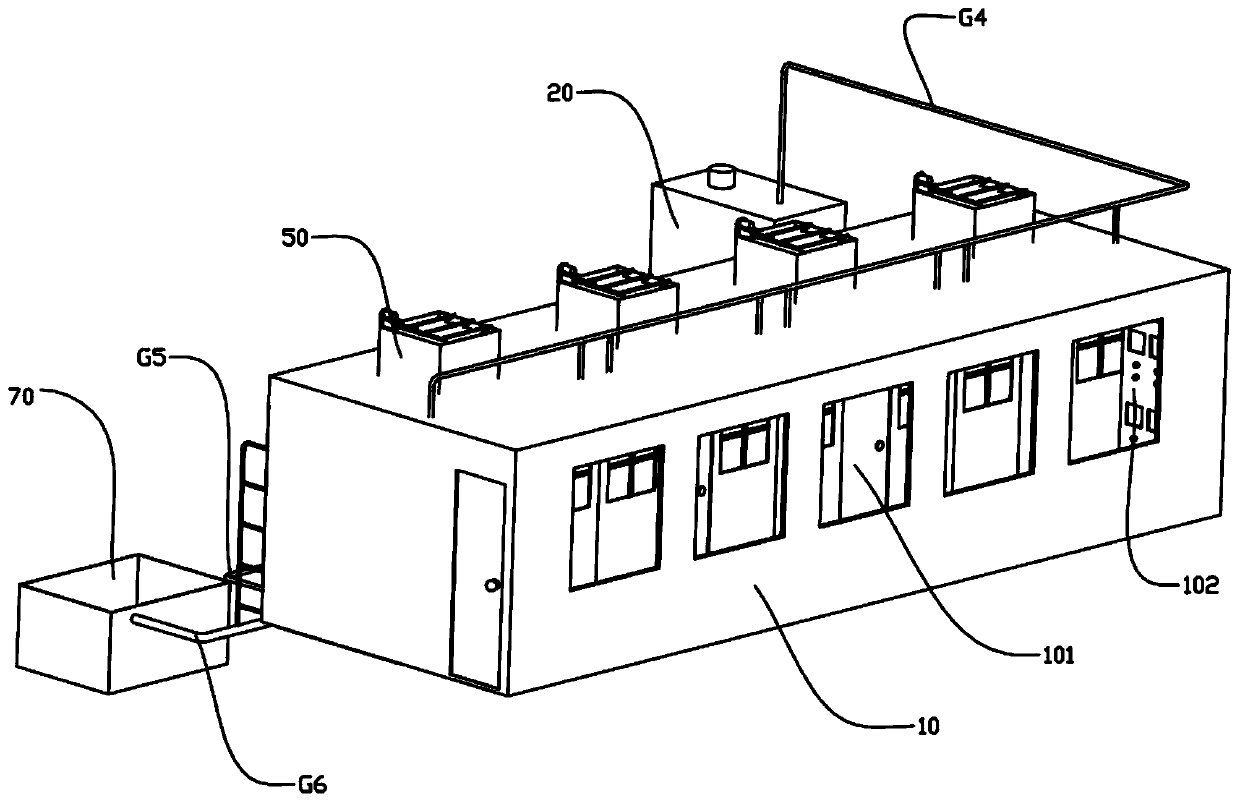

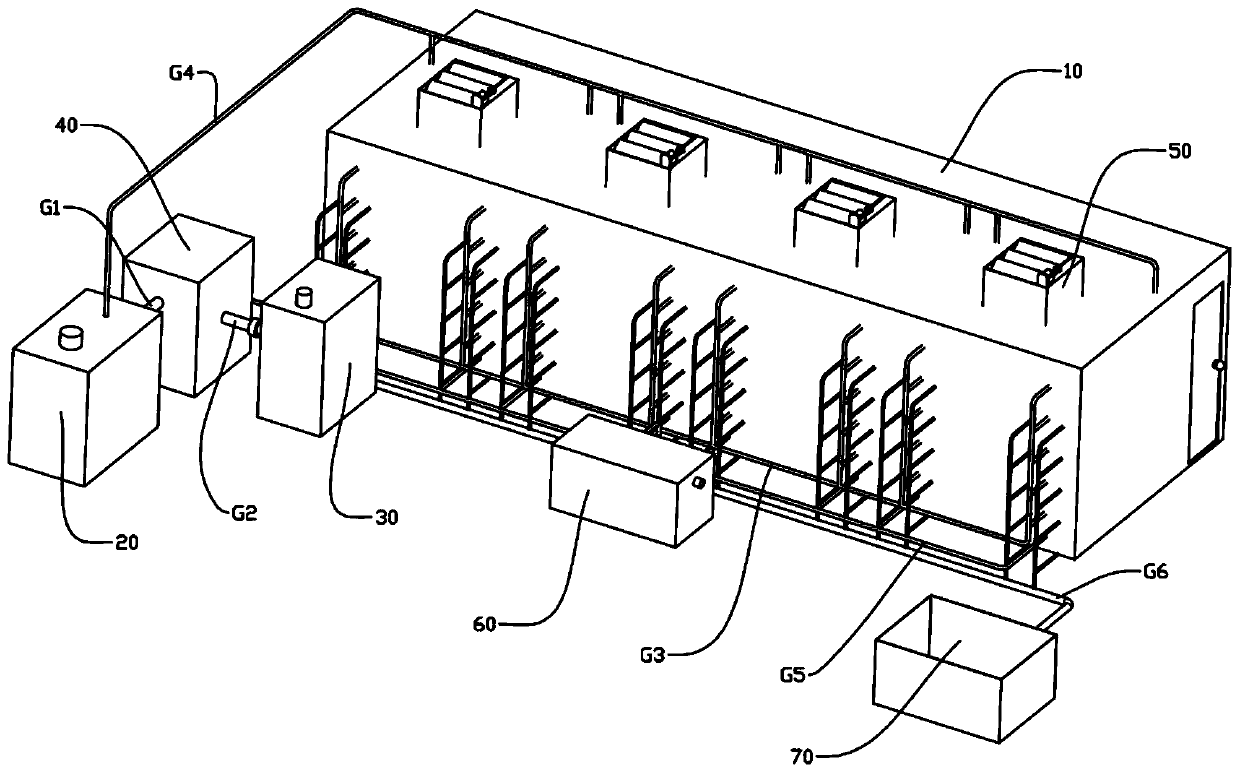

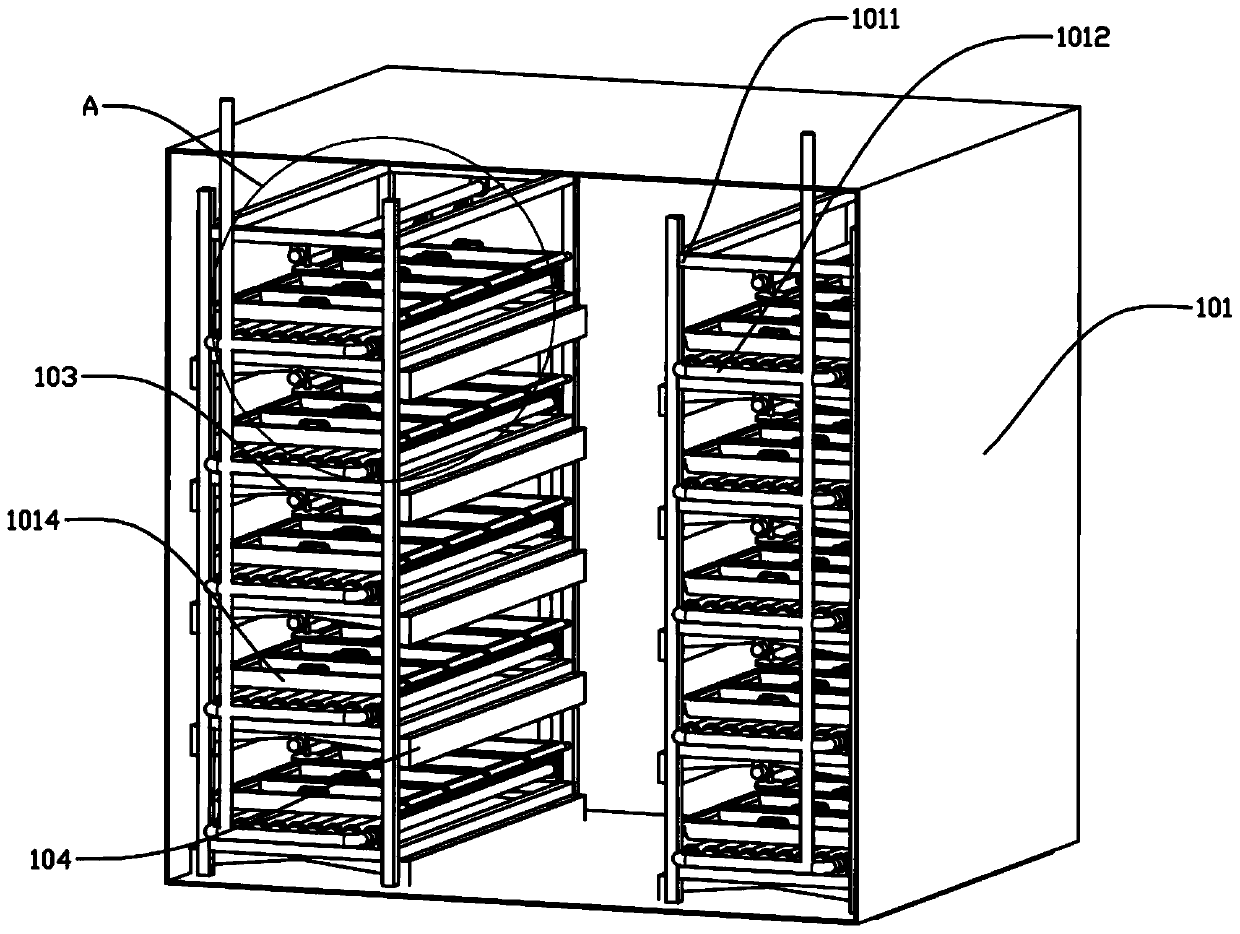

[0026] Please see Figure 1 to Figure 10 , the embodiment of the present invention provides a solid-state fermentation high-activity feed compound enzyme fermentation system, including a fermentation room 10, an air heating box 20, an air cooling box 30, an air mixing device 40, a ventilation and oxygen supplementing device 50, a water supply device, and a waste water The recovery tank 70, the outlet end of the air heating box 20 communicates with the air mixing device 40 through the hot air delivery pipeline G1, and delivers the hot air to the air mixing device 40, and the outlet end of the air cooling box 30 communicates with the air mixing device 40 through the cooling The air conveying pipeline G2 communicates and conveys cold air into the mixing box. The outlet end of the air mixing device 40 communicates with the inside of the fermentation room 10 through the pipeline. The air mixing device 40 mixes hot air and cold air to form mixed air, and The mixed air is transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com