Strong-inhibition bipotassium amine-based ionic polymeric drilling fluid and preparation method thereof

An ionic polymer, double potassium amine-based technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of inconvenient drilling fluid construction and maintenance treatment, inconvenient wellbore stabilization effect, and wellbore stabilization effect. It can achieve the effect of obvious wellbore stabilization, good inhibition of clay hydration and dispersion ability, and improvement of system inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

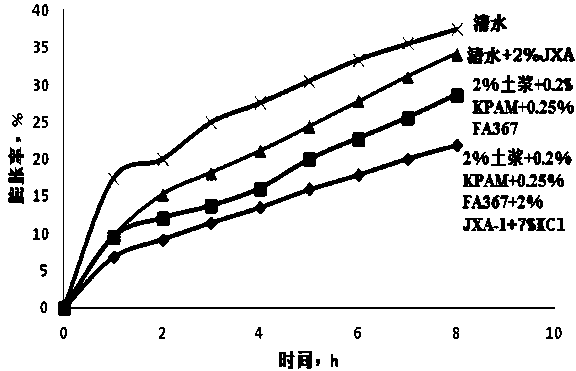

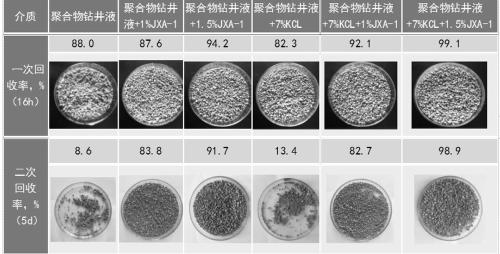

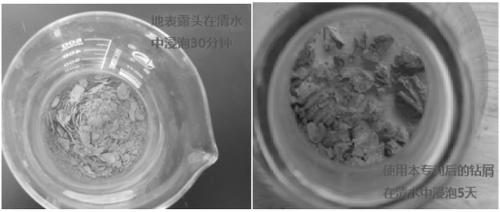

[0029] The Cretaceous and above formations on the right bank of the Amu Darya River in Turkmenistan are long sections of mud shale, with a clay content of about 40%, of which the clay content of illite and illite-smectite layers is 51.9% to 89.1%, with an average content of 72.1%. The fundamental reason for the stability is that from the Xielongian to the Fanlanyin formations, micro-fractures are developed, the width of the fractures is 1.25-18.56um, and the pores are unevenly developed; when the micro-fractured shale formations are drilled, the hydration expansion of the well wall collapses easily. The present invention strongly inhibits the dipotassium amine-based ion polymer drilling fluid for drilling mud shale formations of the Cretaceous and above in the Amu Darya River in Turkmenistan. Or complex downhole problems such as excessive torque during drilling and borehole wall collapse. The synergistic effect of multiple inhibitors has been used to solve the hydration expansi...

Embodiment 2

[0054] As another preferred embodiment of the present invention, this embodiment discloses:

[0055] A kind of strongly inhibited dipotassium amine-based ionic polymer drilling fluid is characterized in that: by mass volume percentage, it comprises the following components:

[0056] Bentonite 3%; caustic soda 0.5%; soda ash 0.3%; polyacrylamide potassium salt KPAM 0.5%; potassium chloride 10%; zwitterionic polymer coating agent FA367 0.2%; shale inhibitor amide polymer JXA-1 0.5%; Fluid loss reducer 0.5%; Viscosifier 0.2%; Viscosity reducer 0.3%; Weighting agent: fine calcium carbonate or barite, the balance is water; The weighting agent increases the density range of 1.10g / cm 3 -2.40g / cm 3 . Preferably, the fluid loss control agent is one or a combination of low viscosity polyanionic cellulose and low viscosity carboxymethyl cellulose. Preferably, the thickener is one or a combination of any two of xanthan gum, high-viscosity polyanionic cellulose, and light subgel. Prefe...

Embodiment 3

[0059] As another preferred embodiment of the present application, this embodiment discloses:

[0060] A kind of strongly inhibited dipotassium amine-based ionic polymer drilling fluid is characterized in that: by mass volume percentage, it comprises the following components:

[0061] Bentonite 5%; caustic soda 0.3%; soda ash 0.25%; polyacrylamide potassium salt KPAM 0.3%; potassium chloride 8%; zwitterionic polymer coating agent FA367 0.8%; shale inhibitor amide polymer JXA-1 0.5%; Fluid loss reducer 0.7%; Viscosifier 0.3%; Viscosity reducer 0.2%; Weighting agent: fine calcium carbonate or barite, the balance is water; The weighting agent increases the density range of 1.10g / cm 3 -2.40g / cm 3 . Preferably, the fluid loss control agent is one or a combination of low viscosity polyanionic cellulose and low viscosity carboxymethyl cellulose. Preferably, the thickener is one or a combination of any two of xanthan gum, high-viscosity polyanionic cellulose, and light subgel. Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack width | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com