Feeding machine for cabinet production line

A production line and feeding machine technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of large feeding resistance, sheet damage, and inconvenient sheets, etc., to achieve stable sheet output, safe and convenient use, Avoid the effect of material jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

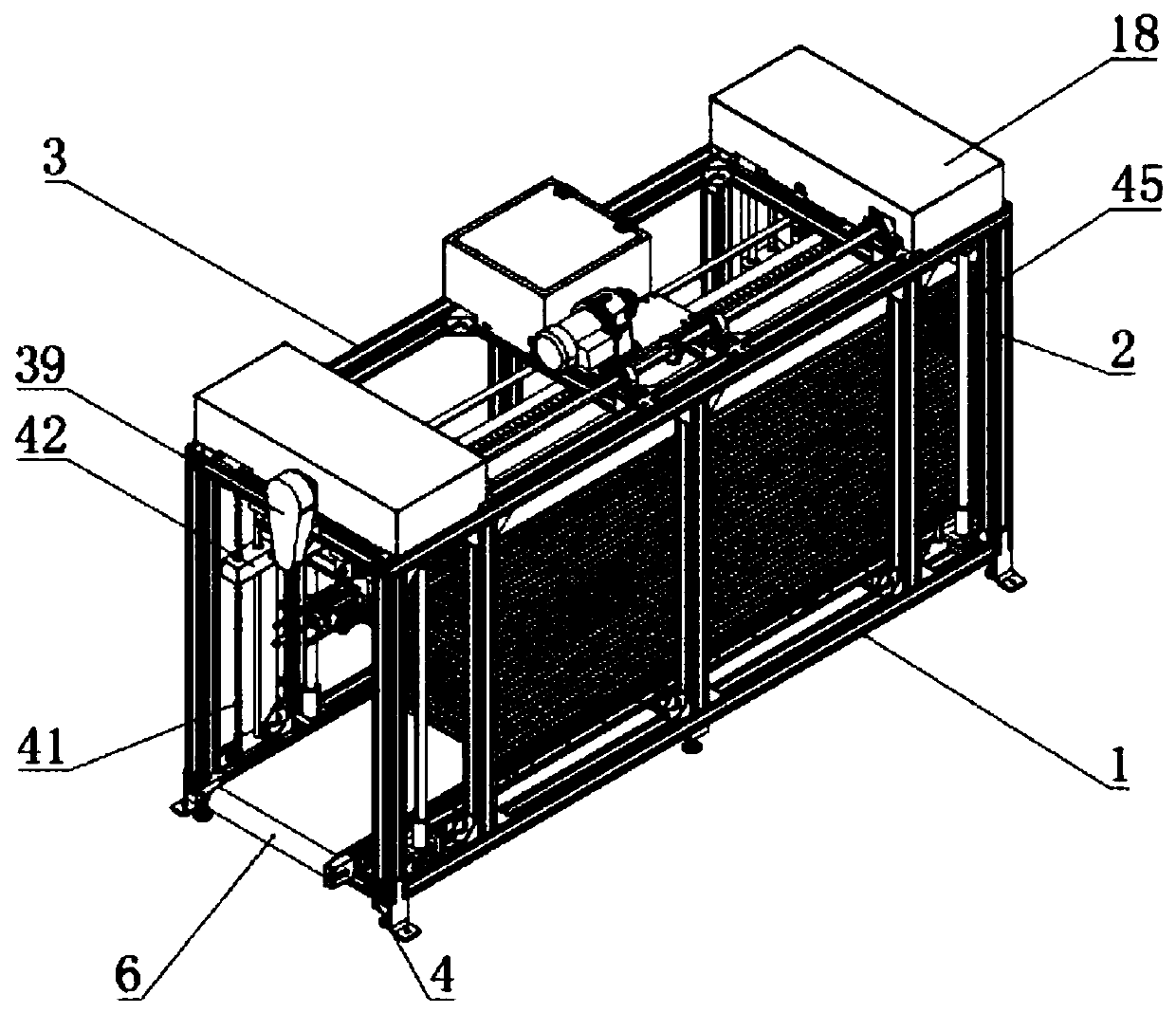

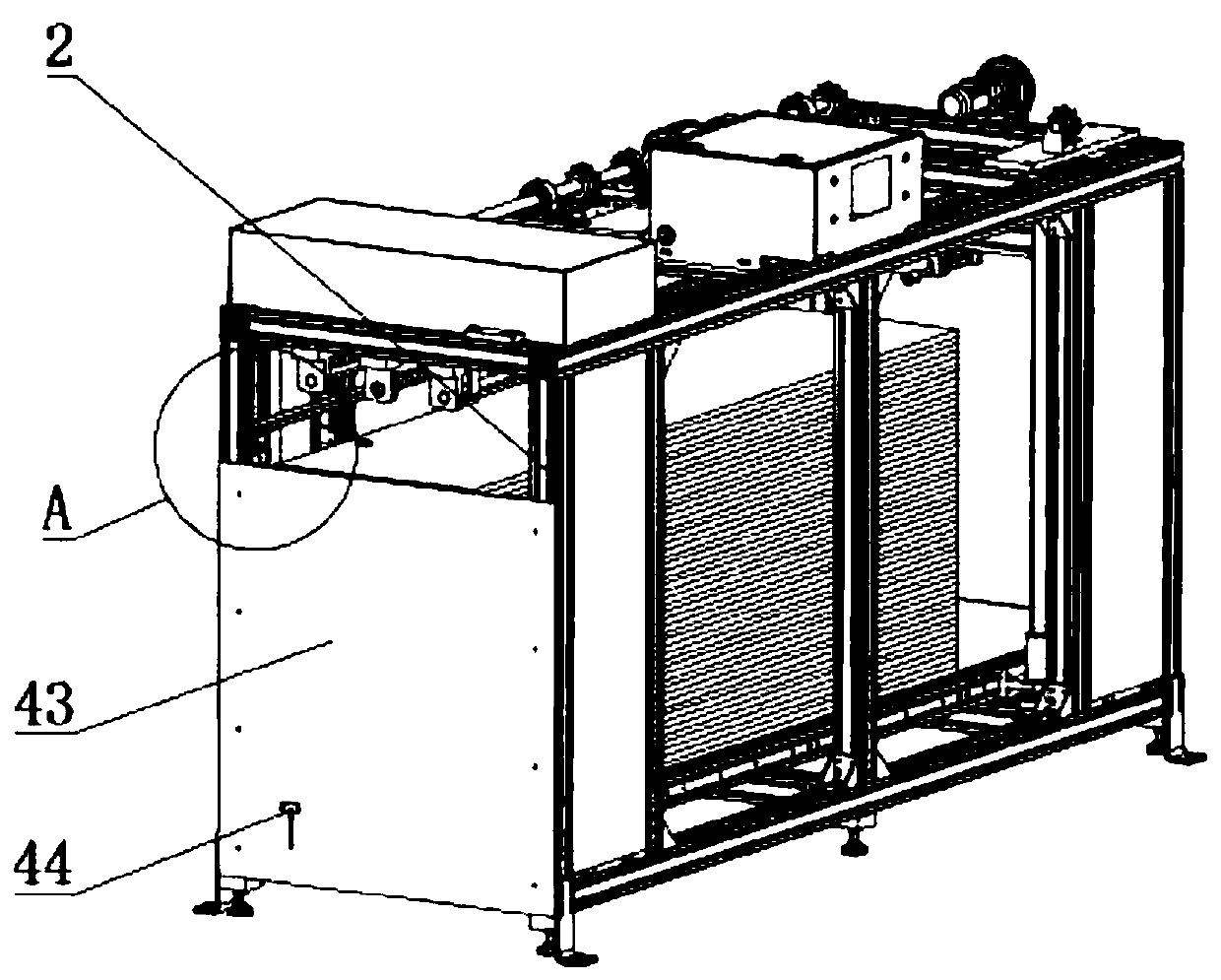

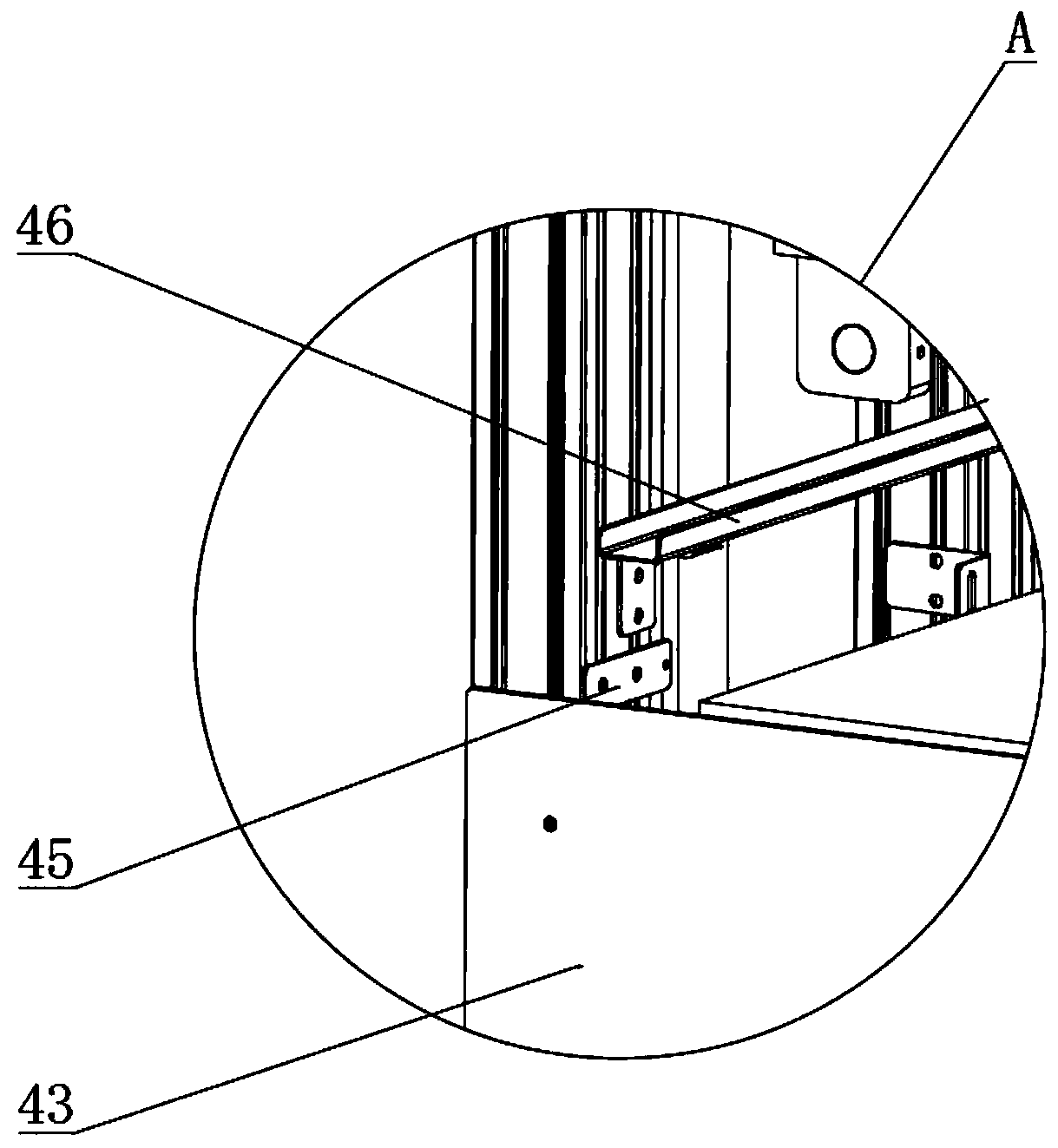

[0040] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a feeding machine for a cabinet production line, including a bottom frame 1, the top of the bottom frame 1 is installed with a top frame 3 through a support column 2, and the middle part of the top of the bottom frame 1 is symmetrical Mounting frame 4 is installed, and transmission drum 5 is installed equidistantly between two mounting frames 4, and one end of transmission drum 5 of mounting frame 4 ends is equipped with feed motor 47, and transmission drum 5 is wrapped with transmission belt 6 outside measurement, installs The first linear bearing 8 is installed on the surface of one side of the frame 4 through the T-shaped fixing seat 7, and the limit column 9 is installed on the side of the bottom frame 1 corresponding to the position of the first linear bearing 8, and the first linear bearing 8 and the limit Column 9 sliding socket connection.

[0041] The bottom of the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com