Low-noise pneumatic tire assembly

A pneumatic tire and low-noise technology, which is applied in the field of low-noise pneumatic tire components, can solve the problems of increasing tire weight, difficulty in repair fluid flow, and high cost, so as to improve the sound absorption and noise reduction effect, increase the effective sound absorption area, and reduce the material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

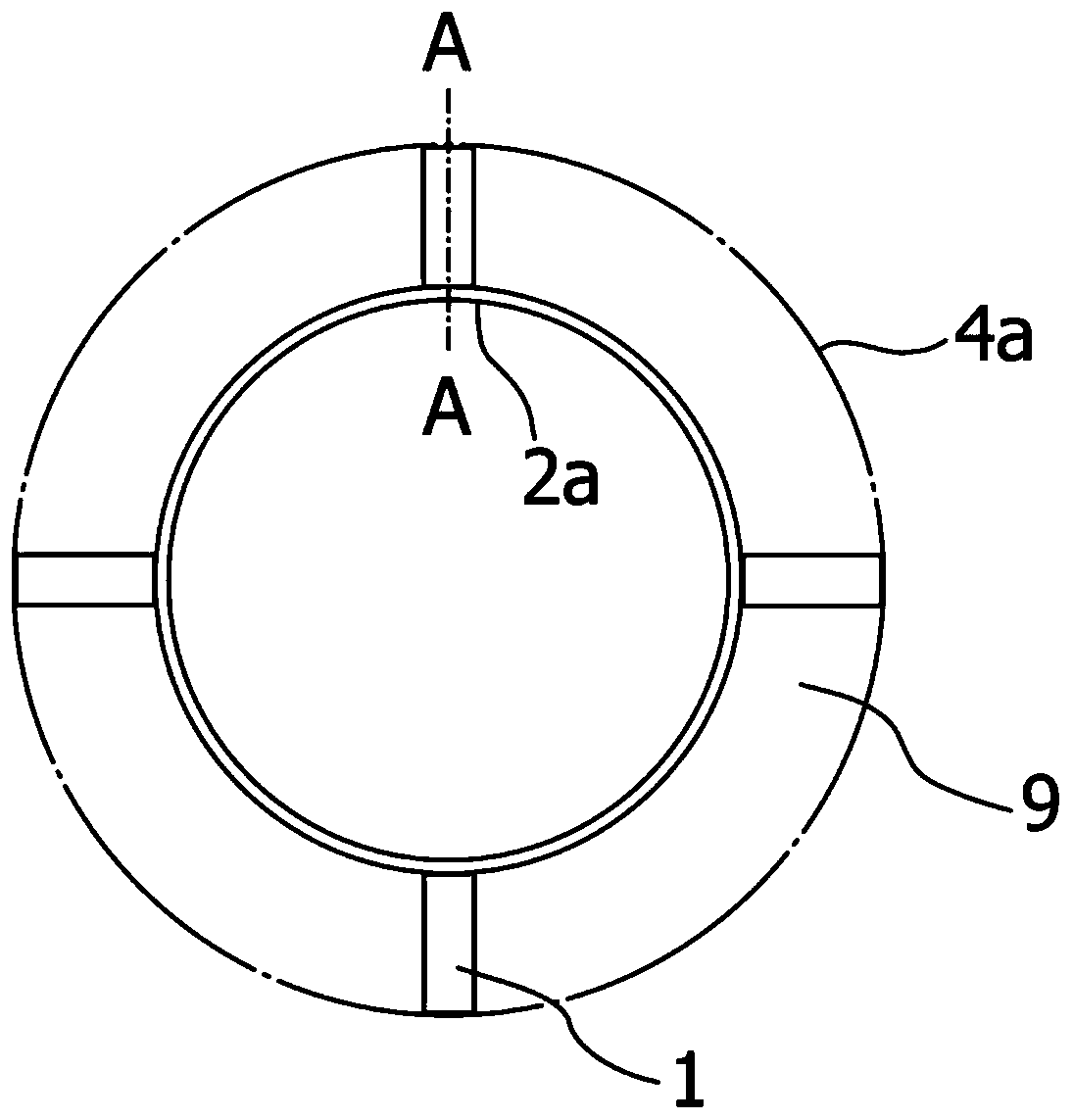

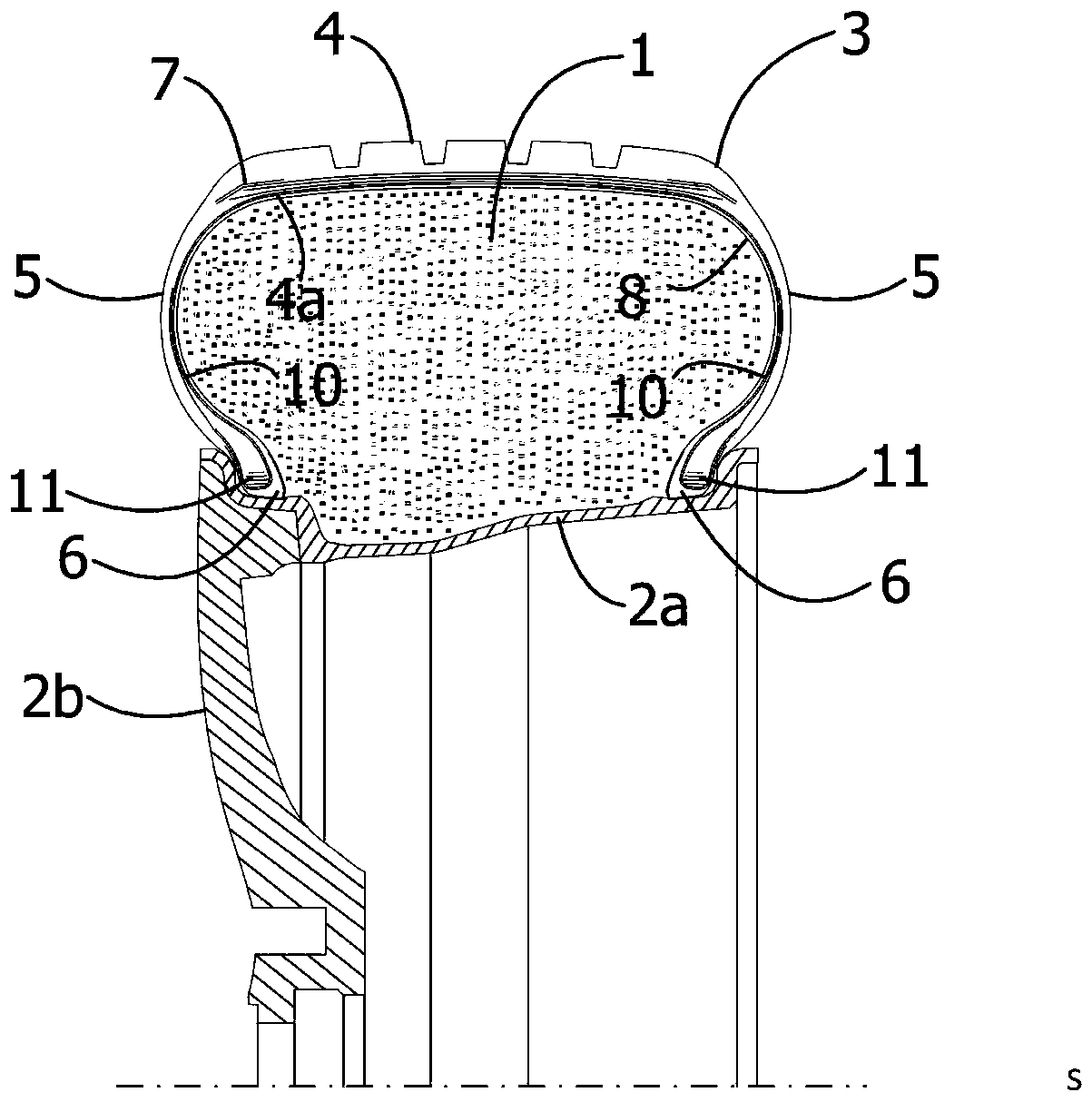

[0032] see figure 1 and figure 2 , the pneumatic tire assembly in this embodiment refers to the pneumatic tire 3 formed with the annular tire cavity 9 by the tread inner surface 4a of the tire and the rim 2a; the pneumatic tire 3 is installed on the rim 2a and supported by the spokes 2b; The tire 3 includes: a tread portion 4, a bead portion 6 on the left and right sides, sidewall portions 5 on the left and right sides connecting the tread portion 4 and the bead portion 6; A carcass 10 extends inside the tire, a belt 7 is provided on the outer peripheral side of the carcass of the tread portion 4, and bead cores 11 are embedded in the left and right bead portions 6, respectively, so that both ends of the carcass 10 are placed on the tire. The ring core 11 is turned back from the inner side of the tire to the outer side; the space surrounded by the tire inner surface 8 forms the cavity of the pneumatic tire 3, and the pneumatic tire 3 is installed on the wheel by sealing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com