A 3D printing device and method for improving the quality of workpiece forming

A 3D printing and molding quality technology, applied in the field of additive manufacturing, can solve problems such as workpiece warping, blackening, and surface spheroidization, and achieve the effects of smooth and uniform airflow, high-quality molding, and atmosphere environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

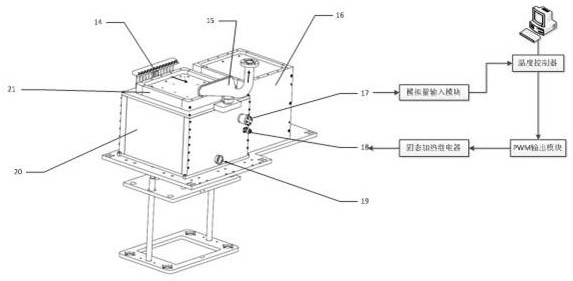

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0036] The scheme of the present invention is simple, practical and reliable, and adopts the advection nozzle, which can realize the uniform passage of airflow in a large area; the invention designs an atmosphere heating box, which can heat the atmosphere in the vacuum box and the wall plate of the processing cylinder, and at the same time, the atmosphere is heated when the workpiece is cooling The box can set a series of cooling temperature values, which reduces the cooling gradient; the blower used is equipped with a corresponding frequency converter, which can realize the free adjustment of the wind speed in the process test; the multi-stage impurity filtering device and the water and oxygen purification device are used to ensure the printing required. atmosphere environment.

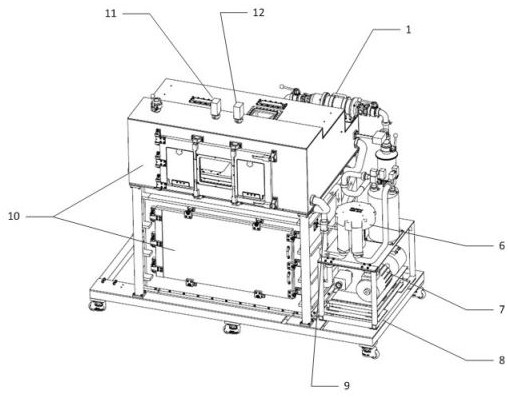

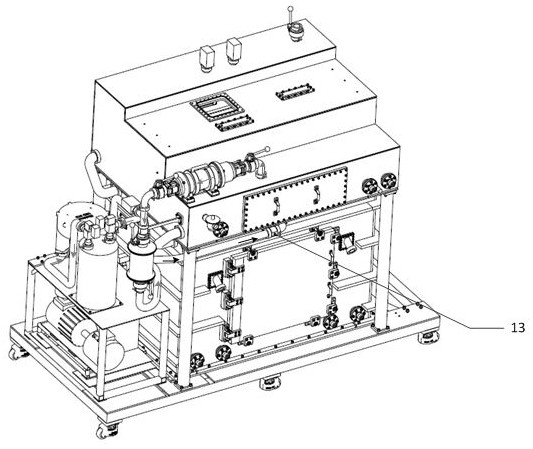

[0037] figure 1 , 2, 3 is a general diagram of a 3D printing device that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com