A Prestressed Shot Peening Forming Method for Integral Ribbed Panels with Broken Ribs

A technology of shot peening and prestressing, which is applied in the field of aircraft manufacturing, and can solve problems such as inability to select, sudden changes in the shape of broken ribs, and affecting the effect of shot peening of wall panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

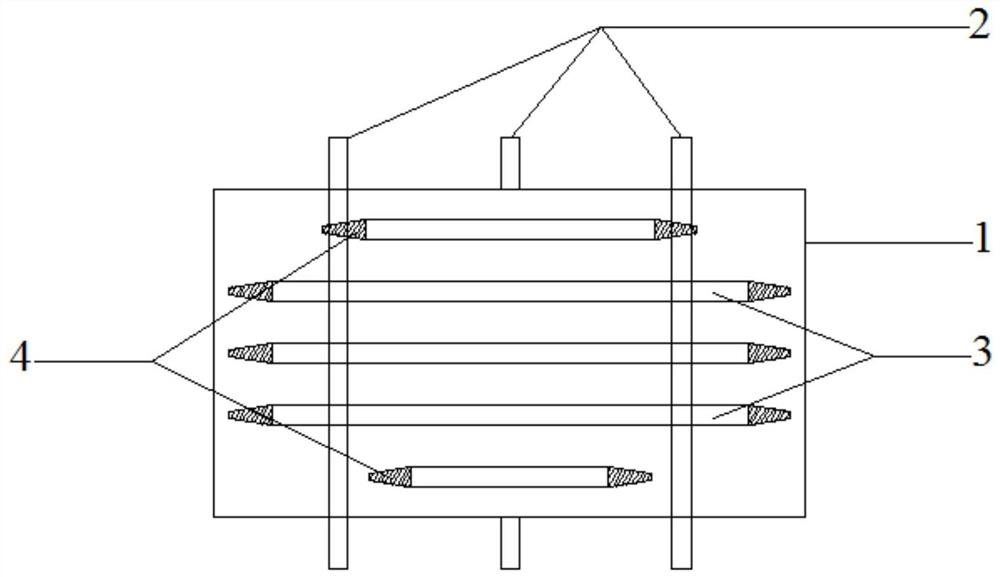

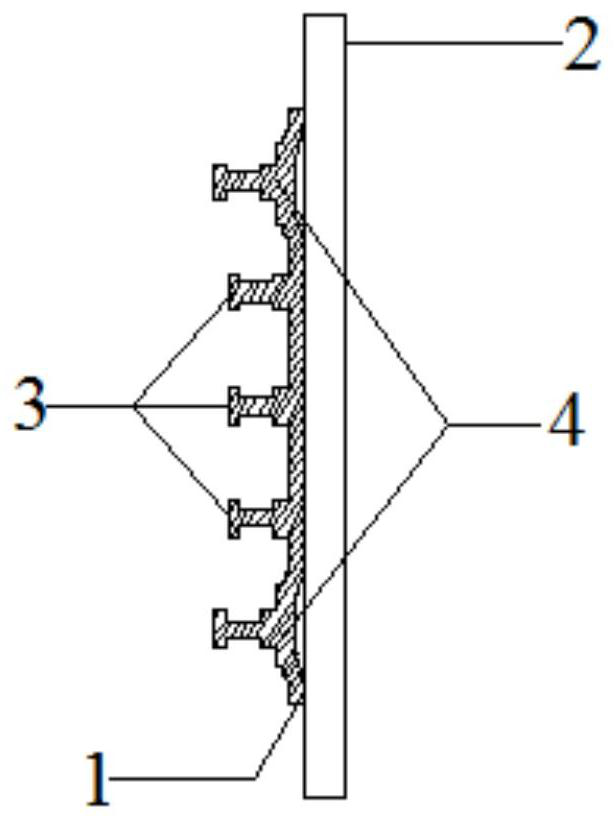

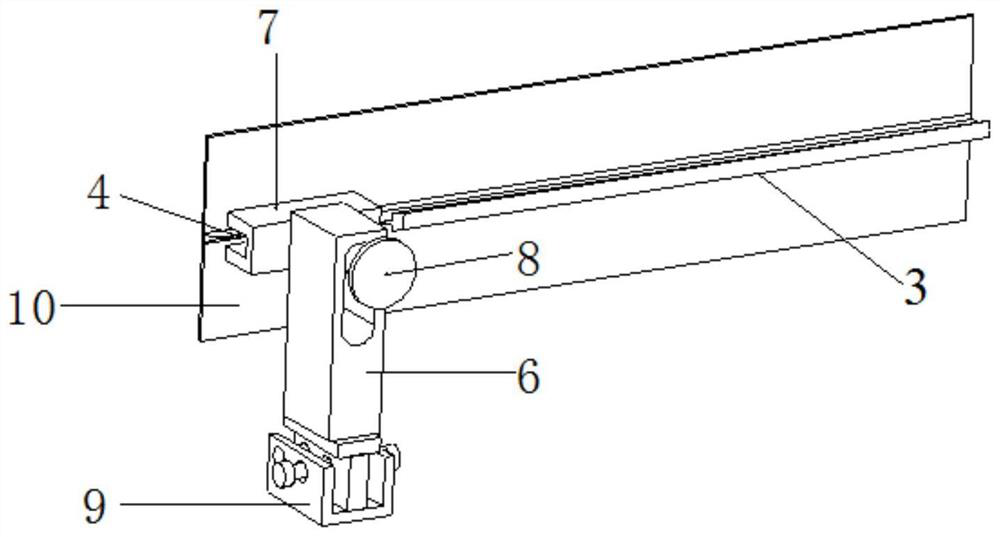

[0023] A prestressed shot-peening forming method for the rib-broken area of an integral ribbed panel, comprising an auxiliary prestressed shot-peening tooling 5, the auxiliary prestressed shot-peening tooling 5 including a connecting support 6, a U-shaped block 7, and a feed bolt 8. The lower part of the connecting support 6 cooperates with the guide rail 9 of the machine tool, slides along the guide rail and can be fixed on the guide rail, the U-shaped block 7 is fixed on the connecting support 6, and the center of the U-shaped block 7 is provided with a blind thread with the feed bolt 8 The hole, the ribbed wall plate broken rib area 4 is stuck in the U-shaped opening of the U-shaped block 7, the U-shaped opening surface is attached to the web surface 10 of the wall plate, and the method for forming includes the following steps:

[0024] 1. Connect the connecting support of the auxiliary prestressed shot-peening forming tooling to the lower guide rail of the machine tool, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com