System for measuring output and cutting off compacted powder

A powder and packaging system technology, applied in the system of measuring output and cutting compacted powder, cutting compacted powder field, which can solve the problems of powder loss, impossible powder accurate dosing and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention is described with reference to specific embodiments as shown in the accompanying drawings. However, the invention is not to be limited to the particular embodiments described in the following detailed description and shown in the drawings, but rather the described embodiments are simply illustrations of various aspects of the invention, the gist of which is defined by the claims. Other modifications and variations of the present invention will be apparent to those skilled in the art.

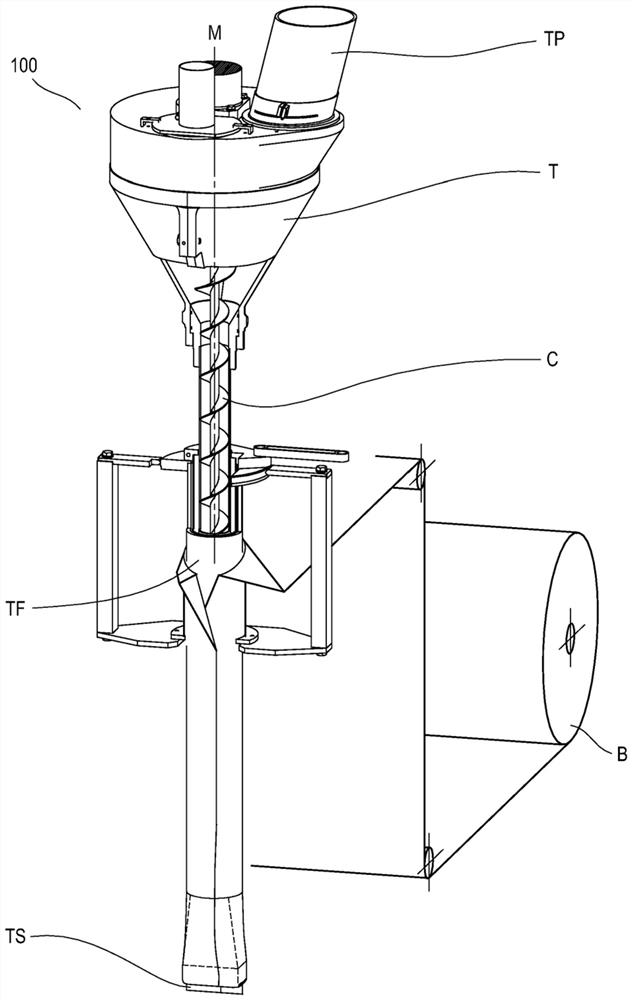

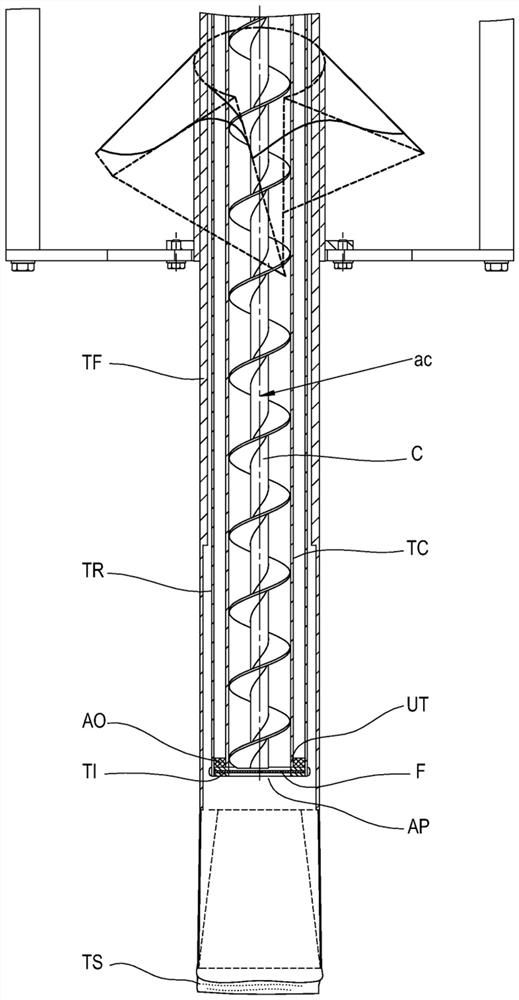

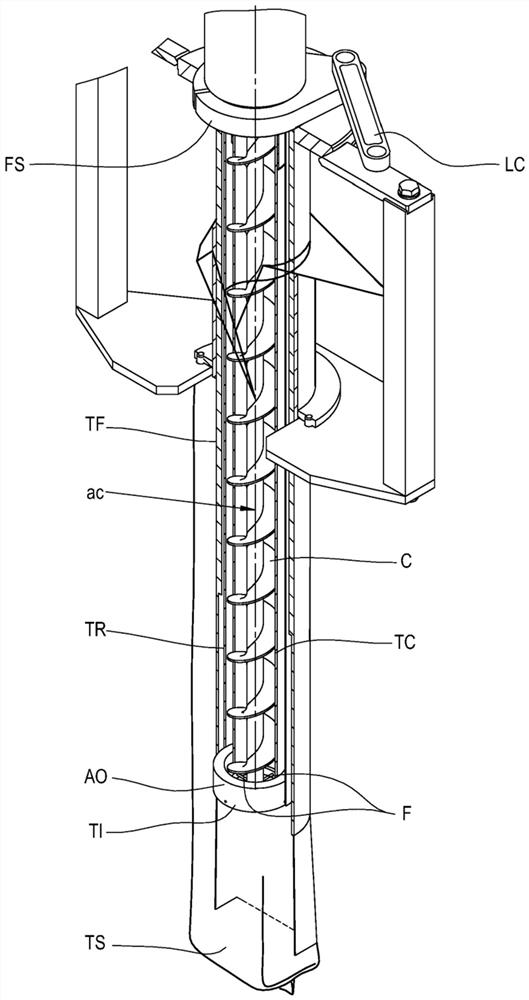

[0049] figure 1 A compacted powder packaging system 100 according to an embodiment of the invention is schematically shown. As shown, the powder packaging system 100 includes a hopper T having an inlet TP through which powder is conveyed into the hopper T. Referring to FIG. In the lower part of the hopper T there is placed a screw conveyor C which, due to its rotation around its own axis ac, conveys the powder inside the tube located in the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com