System and method for switching ship fuel oil

A fuel oil and fuel tank technology, which is applied in charging systems, ship propulsion, liquid fuel feeders, etc., can solve problems such as expensive viscosity, and achieve the effects of improving accuracy, reducing fuel costs, and minimizing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described below with reference to the accompanying drawings. The ship fuel oil switching system and method according to the present invention can be applied to various ships, such as liquefied natural gas carriers, ships using liquefied natural gas as fuel, drilling ships and offshore structures. Furthermore, the ship fuel oil switching system and method according to the present invention can be applied to any engine capable of operating with different types of fuel oil. It should be understood that the present invention can be implemented in various ways and is not limited to the following examples.

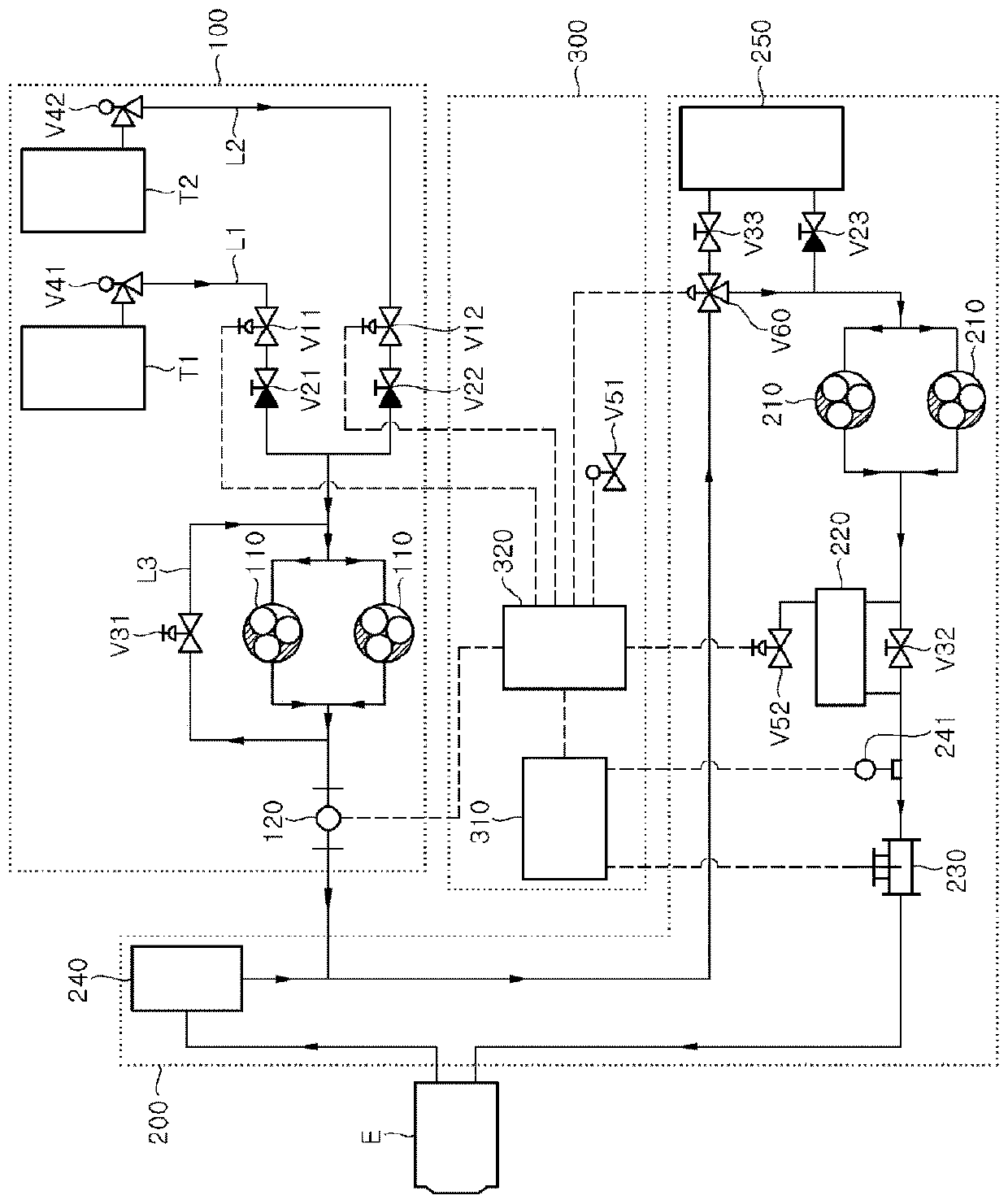

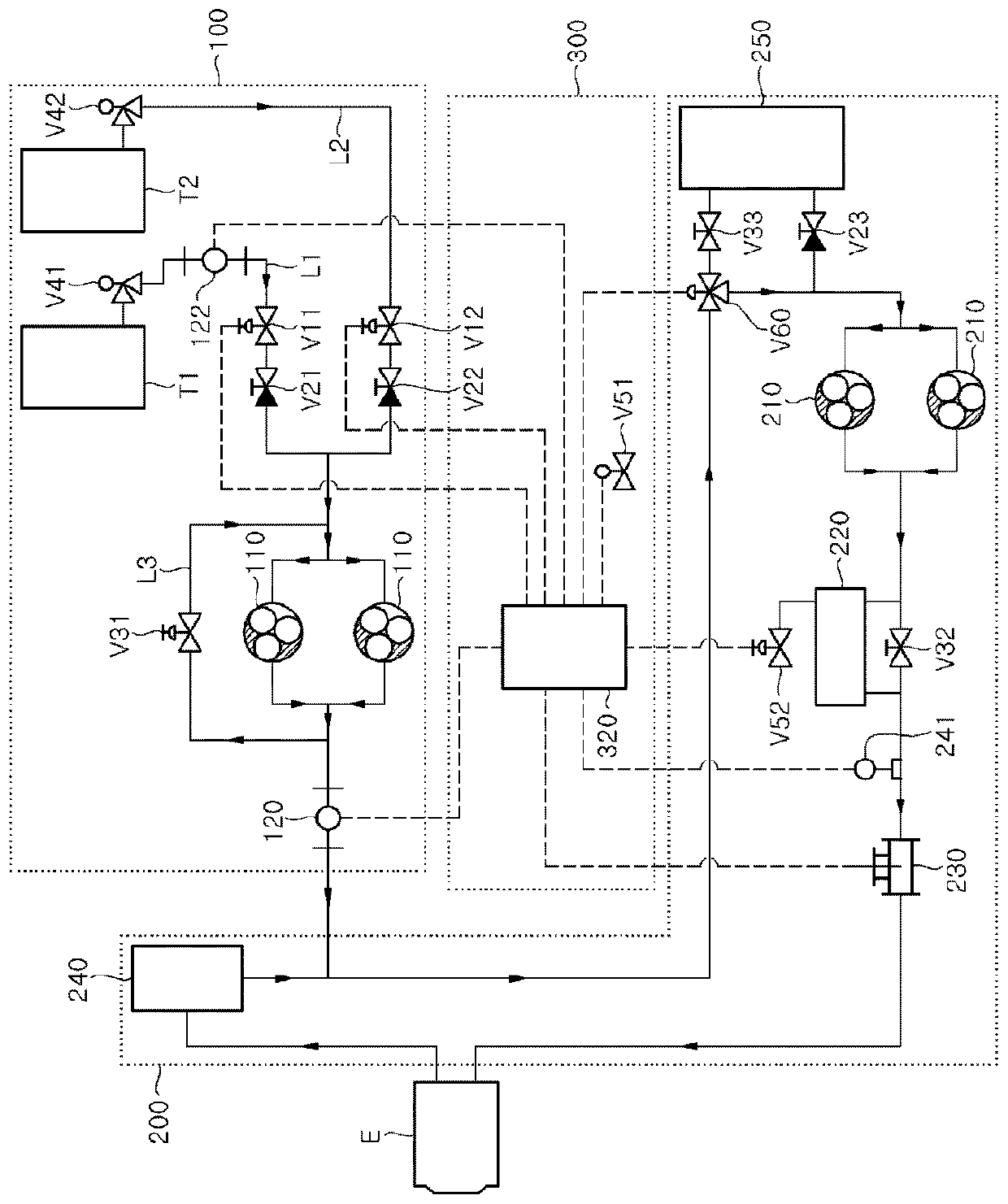

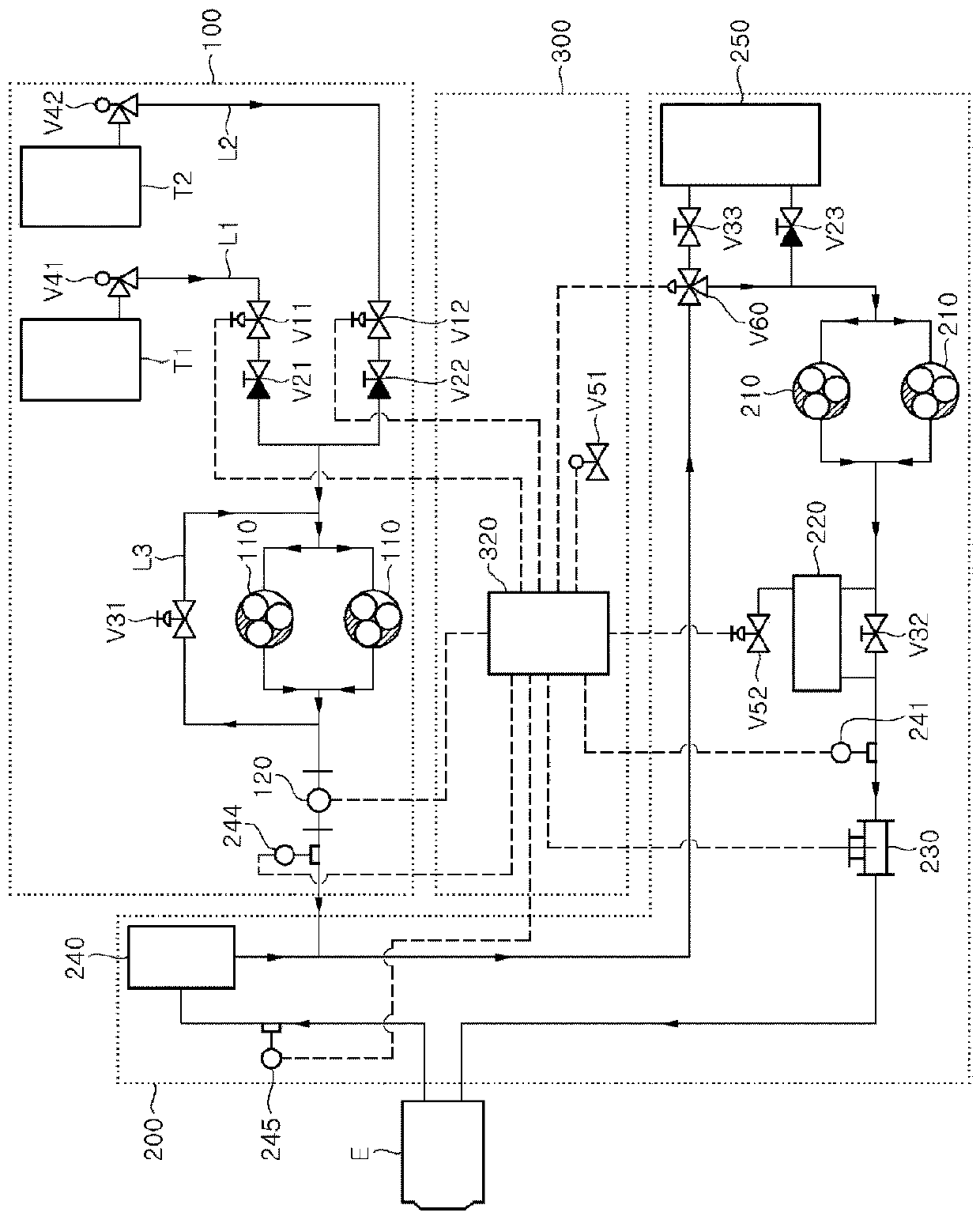

[0041] figure 1 is a schematic diagram of a ship fuel oil switching system according to a first exemplary embodiment of the present invention.

[0042] refer to figure 1 , The ship fuel oil switching system according to this embodiment includes a supply unit (100), a circulation unit (200) and a controller (300).

[0043] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com