Lifting oil cylinder with buffer structure

A lifting cylinder and cushioning structure technology, applied in the direction of lifting devices, fluid pressure actuating devices, etc., can solve the problems of large oil inlet resistance, slow lifting response, and rising oil temperature of the hydraulic system, so as to avoid oil temperature rising , Simple and reliable structure, adjustable cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

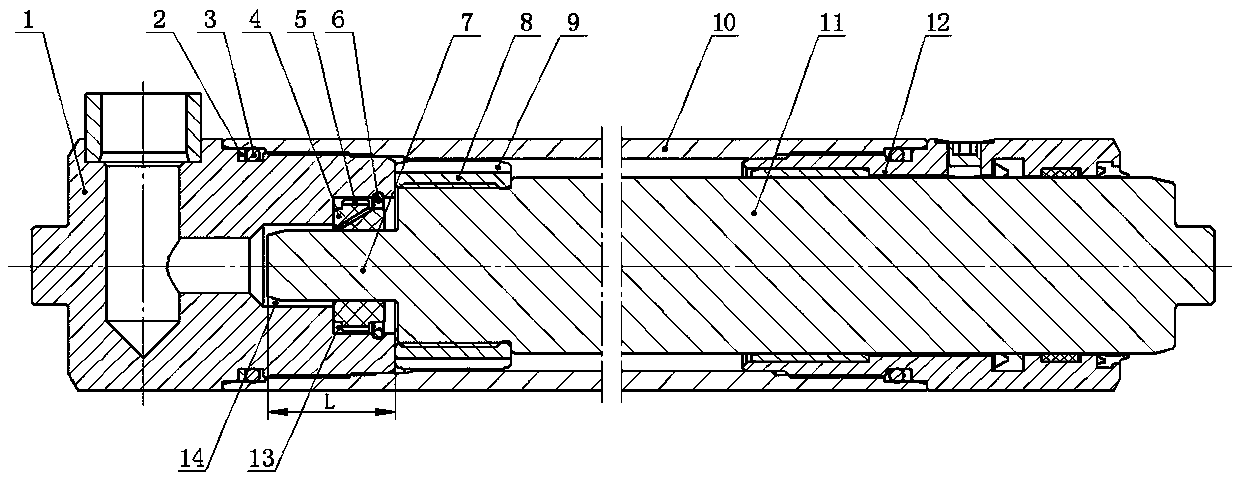

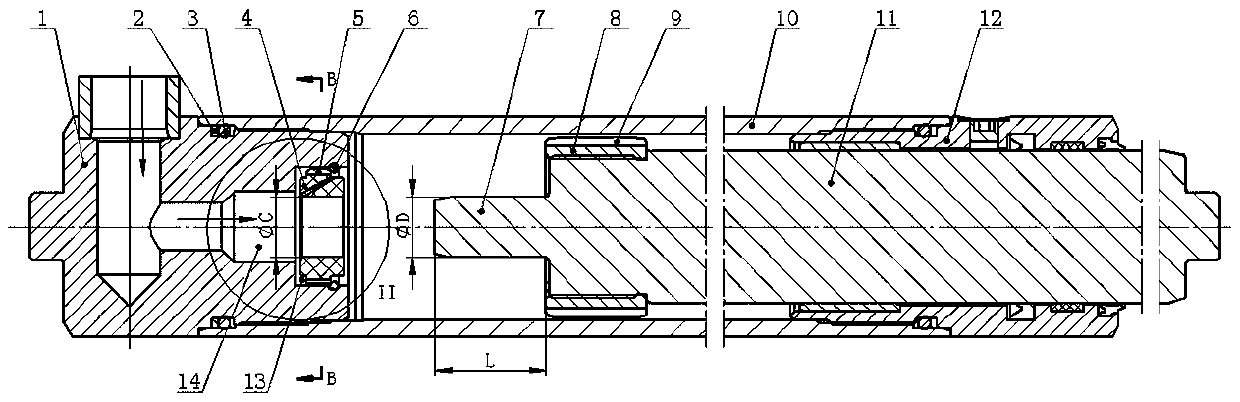

[0037] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0038] see figure 1 with figure 2 , a lifting cylinder with a buffer structure includes a cylinder 10, a cylinder bottom 1, a cylinder head 12, a plunger rod 11, and a plunger 8. The inner diameter of the cylinder 10 is 50 mm. The cylinder bottom 1 and the cylinder head 12 are respectively fixedly mounted on both axial ends of the cylinder barrel 10 . The plunger rod 11 is located in the cylinder barrel 10 , one end extends out of the cylinder head 12 , and the other end corresponds to the cylinder bottom 1 ; the plunger 8 is sleeved on one end of the plunger rod 11 in the cylinder barrel 10 . One end of the cylinder bottom 1 located in the cylinder 10 is provided with a coaxial central oil passage, one side of the cylinder bottom 1 is provided with a radial oil passage, the radial oil passage communicates with the central oil passage, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com