Crane Swing Suspension System

A suspension system and swing-type technology, applied in the direction of cranes, suspensions, elastic suspensions, etc., can solve the problems of large space occupation, large size, and reduced power performance of the whole machine, so as to achieve low manufacturing cost and strong bearing capacity , The effect of ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

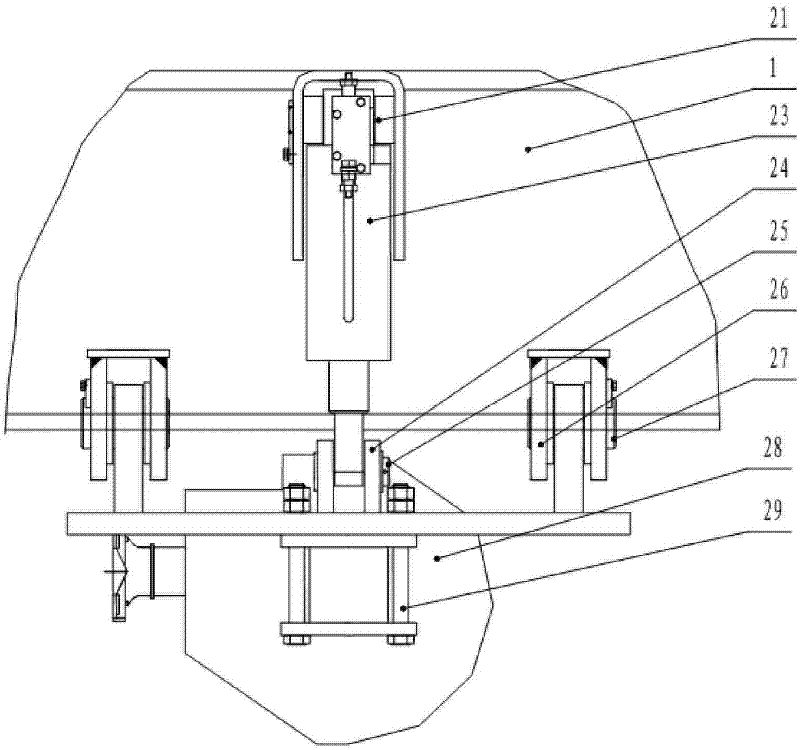

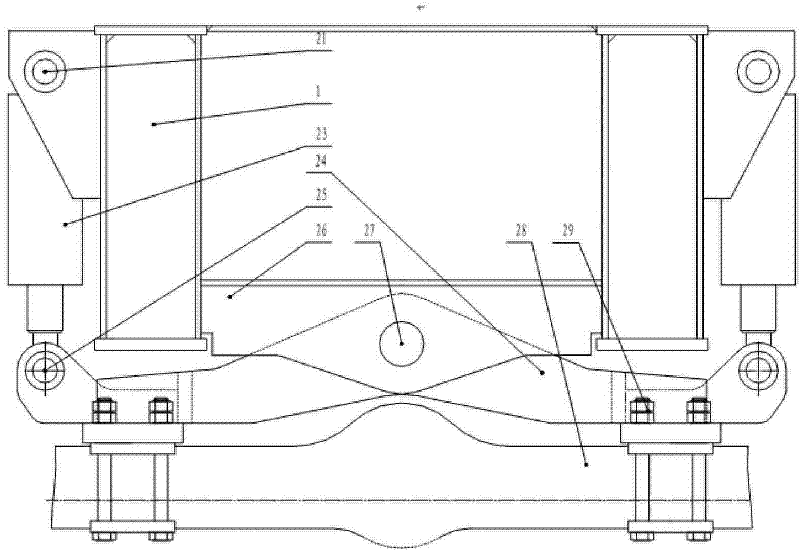

[0025] Specific embodiments of the present invention, such as figure 1 Shown, a kind of crane swing type suspension system, comprises the underframe 1 of vehicle, is equipped with front suspension and rear suspension 4 on underframe 1, and front suspension comprises the front suspension bracket that is welded on the underframe 1 Seat 2, front suspension bearing 2 are rigidly connected together with front drive axle 5 through shock absorbing pad 3 and connecting bolt 4 and are fixed together. Such as figure 2 , 3 As shown, the rear suspension 24 is hinged on the hinged support 26 on the underframe 1 through a pin shaft 27, and the direction of the pin shaft 27 is perpendicular to the direction of the wheel shaft. Two locking oil cylinders 23 are symmetrically arranged on both sides of pin shaft 27, and are installed between rear suspension 24 and underframe 1, preferably, as figure 2 , 3 As shown, the cylinder body of the locking cylinder 23 is hinged to the underframe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com