A system for purification and reuse of construction wastewater from temporary concrete mixing station in highway construction

A wastewater purification and concrete technology, which is applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of lack of degreasing function, complicated maintenance and management, high engineering cost, etc., and improve the effect of precipitation purification , Extensive utilization value, and the effect of increasing hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

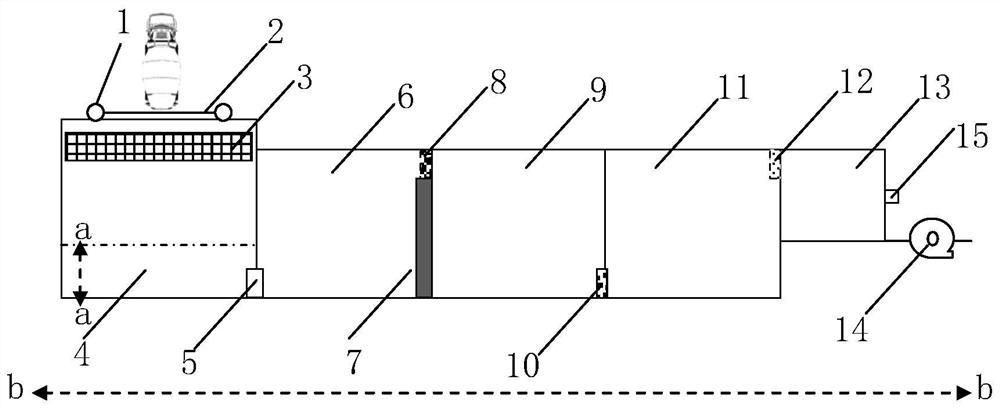

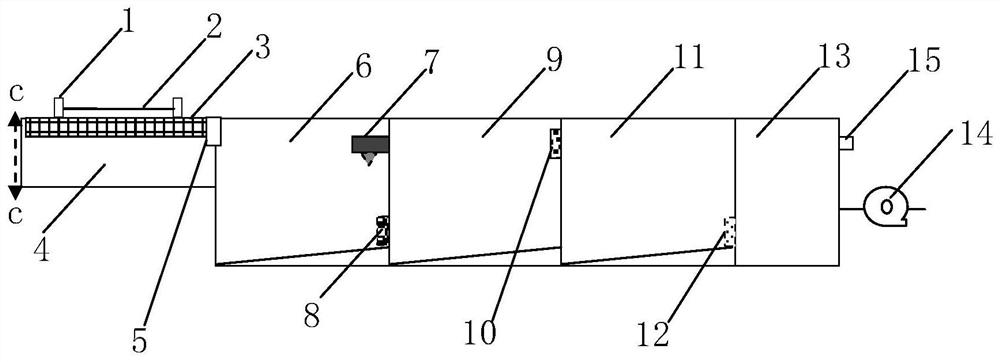

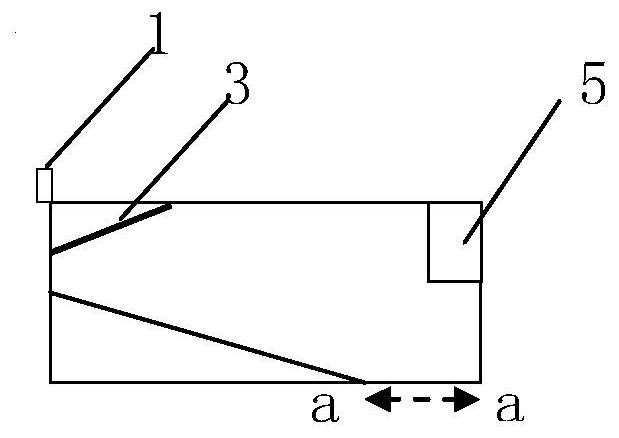

[0066] A method for purifying and reusing construction waste water of a temporary concrete mixing station for highway construction, which specifically includes: after the waste water from the mixing station and the washing waste water of concrete transport vehicles are removed through a grid 3 to remove large-diameter stones, and then collected into a centralized The primary sedimentation tank 4, then enters the primary sedimentation oil separator (6) through the overflow hole (5), adds flocculant, and after sedimentation and oil separation purification, enters the secondary sedimentation filter tank 9 through the filter hole 8, After precipitation and filtration, it enters the tertiary precipitation filter tank 11 through the filter hole 10, and after further precipitation and filtration, it enters the reuse tank 13 through the filter hole 12, and the reused water pump 14 is used for comprehensive utilization of the treated wastewater. The primary sedimentation tank 4 is commu...

experiment example 1

[0068] Experimental Example 1 See Example 1 for the specific construction wastewater purification and reuse treatment method of temporary concrete mixing station for highway construction, in which polyaluminum chloride (PAC) was added as a flocculant in the primary sedimentation grease trap.

experiment example 2

[0069] Experimental Example 2 See Example 1 for the specific construction wastewater purification and reuse treatment method of temporary concrete mixing station for highway construction, in which polyferric sulfate (PFS) was added as a flocculant in the primary sedimentation grease trap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com