Multiaxial robot stacking workstation with positioning function

A multi-axis and robotic technology, applied in the field of palletizing workstations, can solve problems such as low work efficiency, small work range, and small number of arms, and achieve the effect of high work efficiency and wide work range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

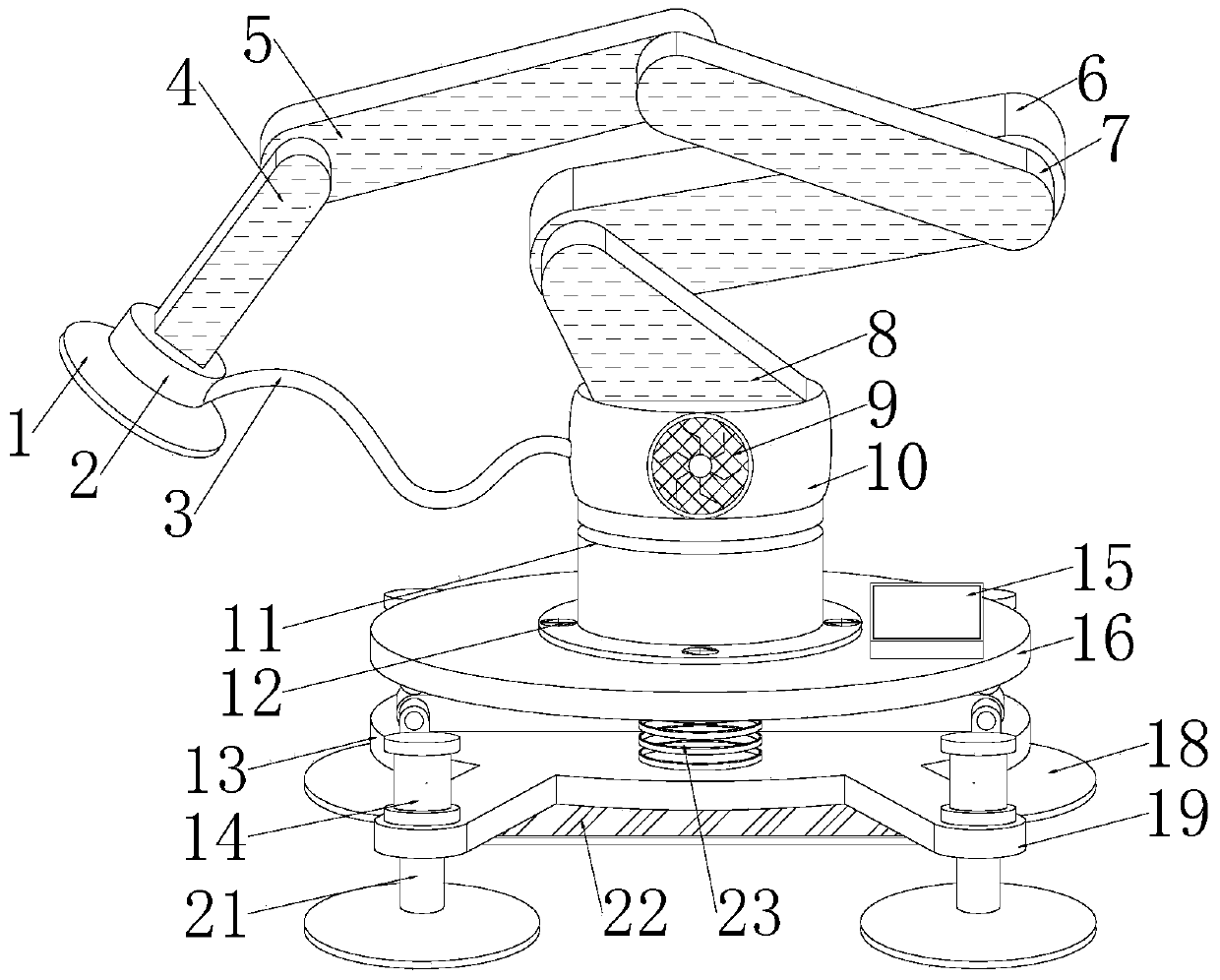

[0033] Such as Figure 1-7As shown, the present invention provides a multi-axial robot palletizing workstation with a positioning function, including a base 13 and a motor housing 11, four extension frames 19 that are symmetrically distributed in the center are welded to the edge of the base 13, and the extension frames 19 A hydraulic cylinder 14 is installed on the top, and a crawler machine 22 is installed on the bottom of the base 13, and the crawler machine 22 and the base 13 are connected by a connecting frame 37 arranged on the top of the crawler machine 22. Spring 23, the top of spring 23 is equipped with receiving platform 16, and the bottom of spring 23 is welded with base 13, and the top abuts with receiving platform 16, and the bottom of receiving platform 16 is equipped with first support 29 and second support 31, and The first support 29 and the second support 31 are arranged crosswise, the top of the receiving platform 16 is equipped with a controller 15, the ins...

Embodiment 2

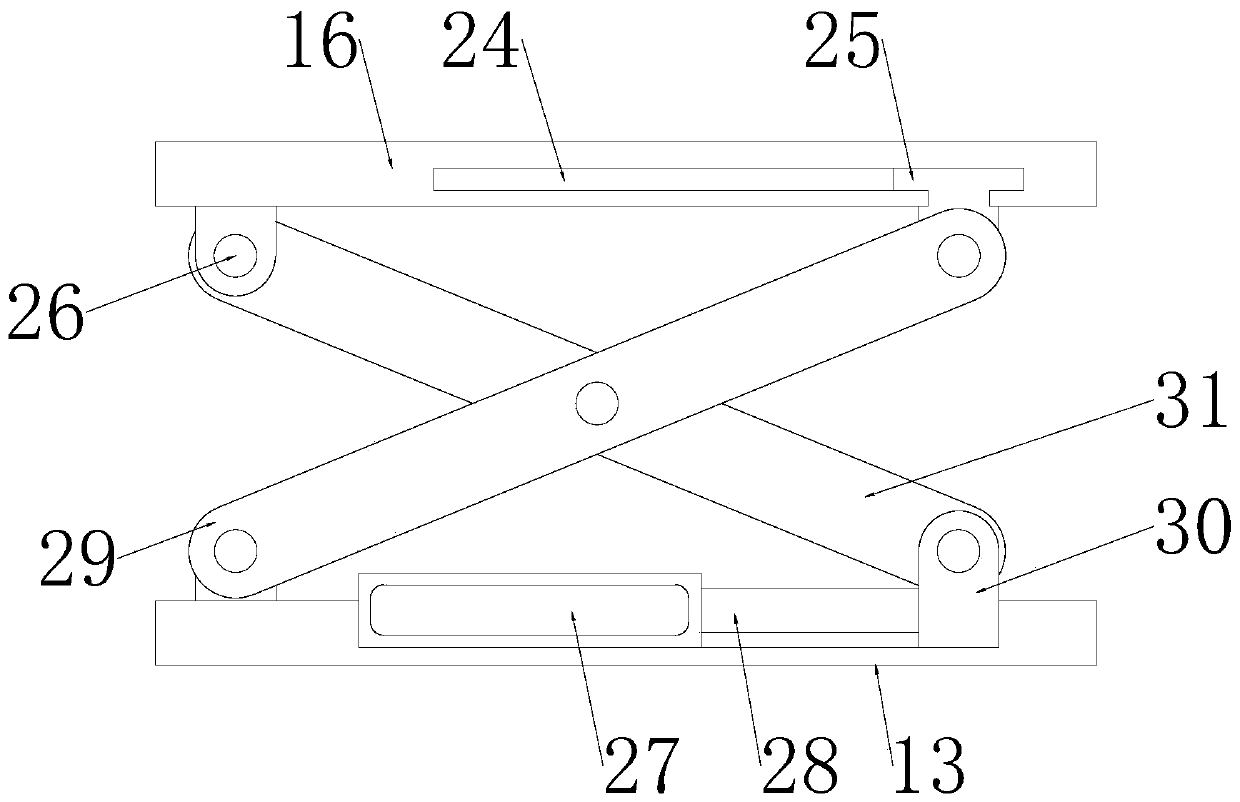

[0036] In a preferred embodiment, the motor housing 11 is connected to the receiving platform 16 by the screws 12 arranged at the bottom of the motor housing 11, and the top and bottom of the first bracket 29 and the second bracket 31 are equipped with connectors 30, and the first bracket 29 and the second bracket 31 are connected with the connecting member 30 through the pin shaft 26 arranged on the side of the connecting member 30 . The central positions of the first support 29 and the second support 31 are connected by the pin shaft 26 arranged in the central area of the first support 29, and the tops of the first support 29 and the second support 31 are connected with the receiving platform 16 by a connecting piece 30, the first Bottoms of the bracket 29 and the second bracket 31 are connected to the base 13 through a connecting piece 30 .

Embodiment 3

[0038] In a preferred embodiment, a slider 25 is welded to the top of the top connector 30 of the first bracket 29 , and the slider 25 is embedded in the slide groove 24 inside the receiving platform 16 and fits with the inner wall of the receiving platform 16 in clearance. The bottom of the second bracket 31 bottom connector 30 is welded with a telescopic tube 28, and one end of the telescopic tube 28 is equipped with a cylinder 27, and the cylinder 27 is embedded in the base 13, and the inside of the fan housing 10 is equipped with a fan 36, cylinder 27, hydraulic pressure The cylinder 14 , the infrared sensor 32 , the second motor 17 , the fan 36 , the first motor 35 and the crawler 22 are all electrically connected to the controller 15 . According to the height position of the transported object, the height of the receiving platform 16 can be adjusted. The adjustment process is that the cylinder 27 works, and the connecting piece 30 at the bottom of the second support 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com