Hot forging die upper die with internal cooling function and cooling method thereof

A hot forging die and functional technology, applied in heating/cooling equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of reducing die life, pollution of workshop working environment, and ejection force of die and forging bonding , to achieve sufficient cooling, improve manufacturability, and improve the effect of mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

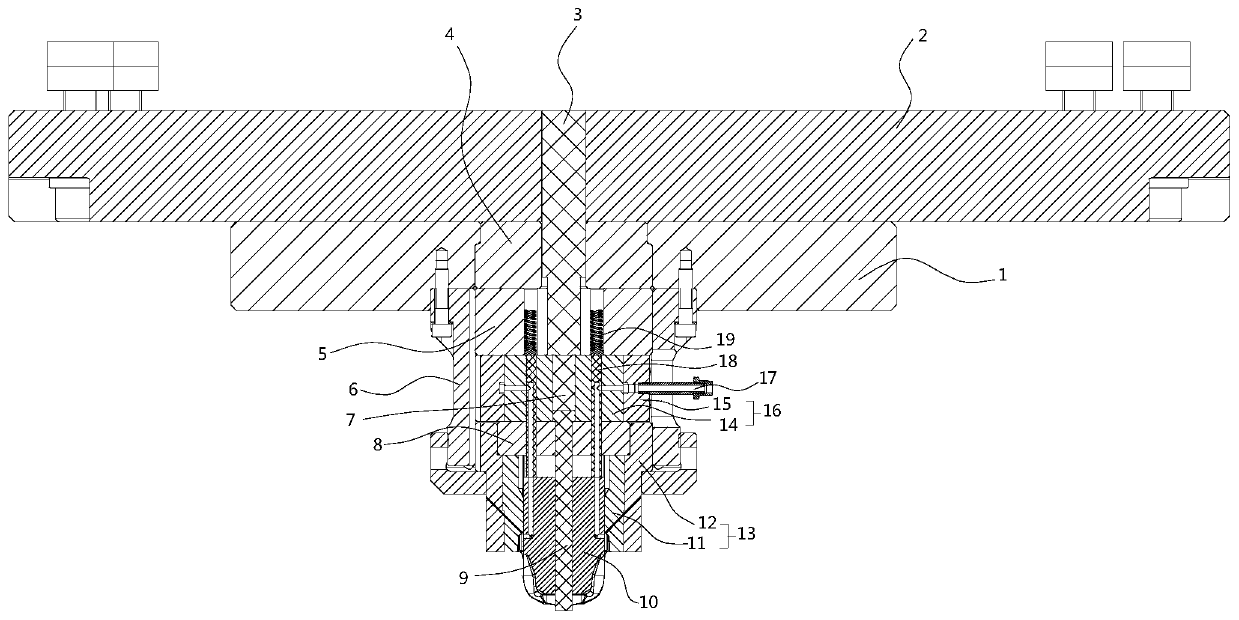

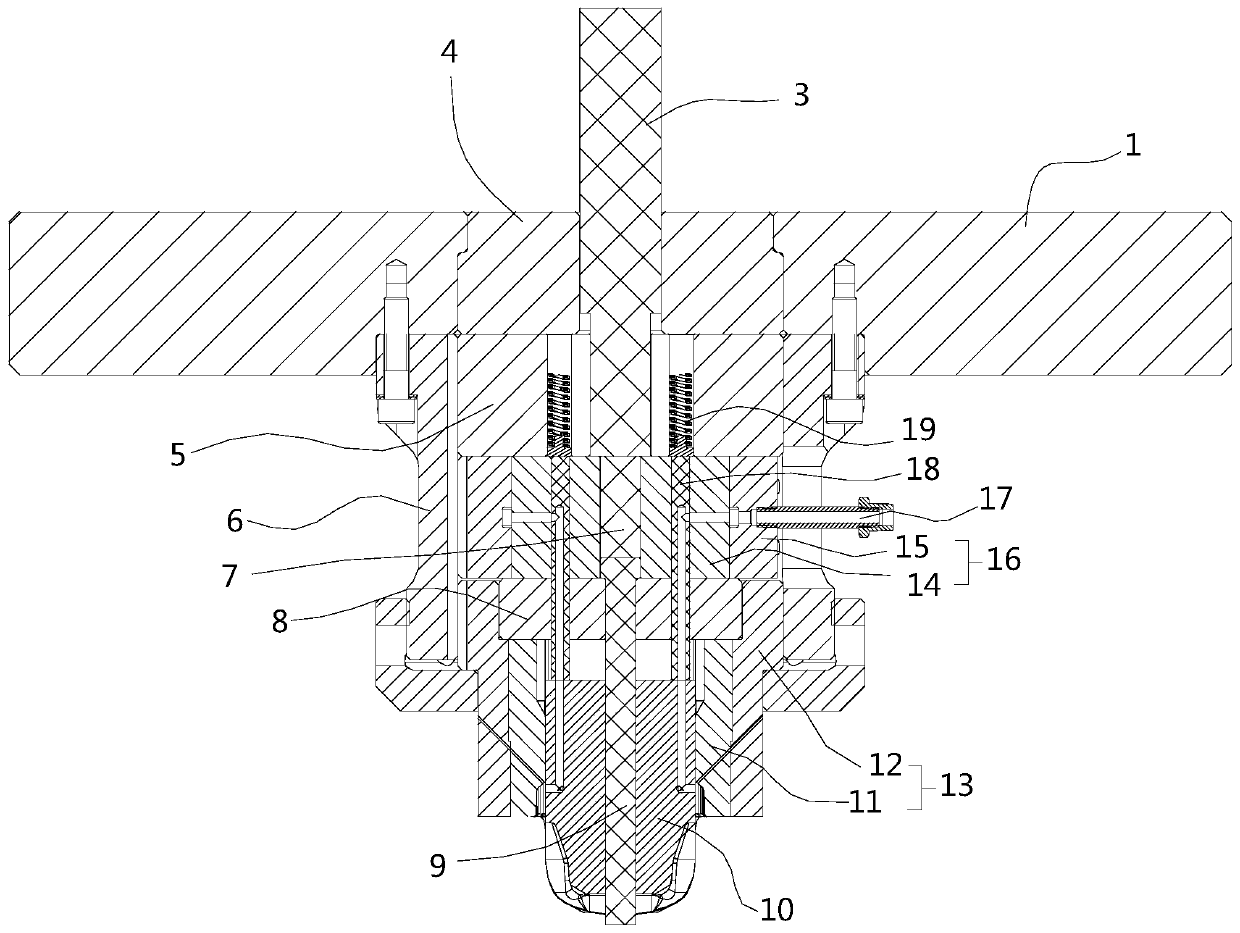

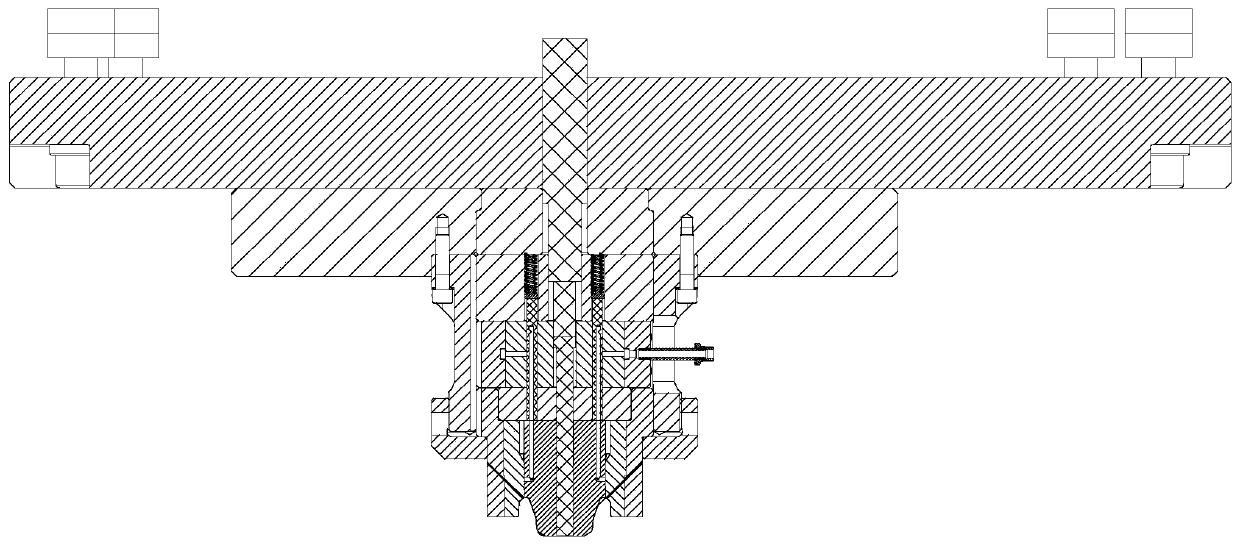

[0040] figure 1 It is a schematic diagram of the working state of the upper mold internal cooling system of the upper mold of the present invention, figure 2 yes figure 1The enlarged view after removing the upper backing plate, combined with these two figures, it can be seen that the upper die of the present invention is equipped with a mold frame system, a feeding mechanism, a punch assembly, a punch support pad system and a punch internal cooling system. The formwork system includes a horizontally arranged upper backing plate 2 , the lower surface of the upper backing plate 2 is closely fixed with an upper formwork 1 , and the upper formwork 1 and the upper backing plate 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com