A New Method for Butt-connection of 10kv Large-capacity Overhead Line Leads

An overhead line, large-capacity technology, applied in the direction of line/collector components, circuits, connections, etc., can solve the problems of high resistivity of the contact surface, serious power loss, difficulty in docking stability and quality assurance, and achieve non-stop shares, saving power loss, and stable docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A new method for connecting leads of 10k V large-capacity overhead lines, comprising the following steps:

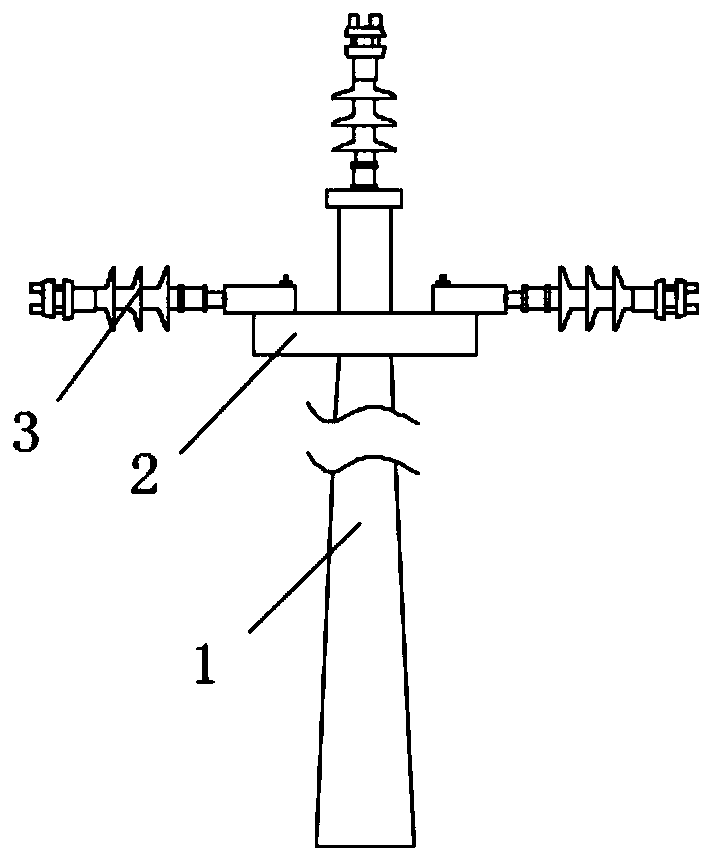

[0046] S1: Preparation before docking, install insulators at the docking position of the lead wires of the overhead line, the insulators are installed on the iron cross arm and form an insulator string, the insulator string can be flexibly rotated in the direction of the line and in the direction of the vertical line, the specific steps as follows:

[0047] The upturned angle of the end of the iron cross-arm is 5° to prevent the wire or lead wire from slipping off;

[0048] The insulator is a pin-type insulator, which is installed vertically on the iron cross-arm, and is fixed with spring washers or double nuts to prevent loosening;

[0049] And / or, the insulator is an all-ceramic cross-arm insulator, and rubber gaskets are added when installing on the iron cross-arm to prevent surface damage of the all-ceramic cross-arm insulator due to friction.

[0050] S2: P...

Embodiment 2

[0075] A new method for connecting leads of 10k V large-capacity overhead lines, comprising the following steps:

[0076] S1: Preparation before docking, install insulators at the docking position of the lead wires of the overhead line, the insulators are installed on the iron cross arm and form an insulator string, the insulator string can be flexibly rotated in the direction of the line and in the direction of the vertical line, the specific steps as follows:

[0077] The upturned angle of the end of the iron cross-arm is 7.5° to prevent the wire or lead wire from slipping off;

[0078] The insulator is a pin-type insulator, which is installed vertically on the iron cross-arm, and is fixed with spring washers or double nuts to prevent loosening;

[0079] And / or, the insulator is an all-ceramic cross-arm insulator, and rubber gaskets are added when installing on the iron cross-arm to prevent surface damage of the all-ceramic cross-arm insulator due to friction.

[0080] S2:...

Embodiment 3

[0105] A new method for connecting leads of 10k V large-capacity overhead lines, comprising the following steps:

[0106] S1: Preparation before docking, install insulators at the docking position of the lead wires of the overhead line, the insulators are installed on the iron cross arm and form an insulator string, the insulator string can be flexibly rotated in the direction of the line and in the direction of the vertical line, the specific steps as follows:

[0107] The upturned angle of the end of the iron cross-arm is 10° to prevent the wire or lead wire from slipping off;

[0108] The insulator is a pin-type insulator, which is installed vertically on the iron cross-arm, and is fixed with spring washers or double nuts to prevent loosening;

[0109] And / or, the insulator is an all-ceramic cross-arm insulator, and rubber gaskets are added when installing on the iron cross-arm to prevent surface damage of the all-ceramic cross-arm insulator due to friction.

[0110] S2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com