Cabin butt-joint bolt connection looseness simulation method under basic excitation

A technology for connecting loose and butt bolts, used in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as preload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] In the present invention, the method for simulating the connection loosening of the butt joint bolts of the cabin section under foundation excitation comprises the following steps:

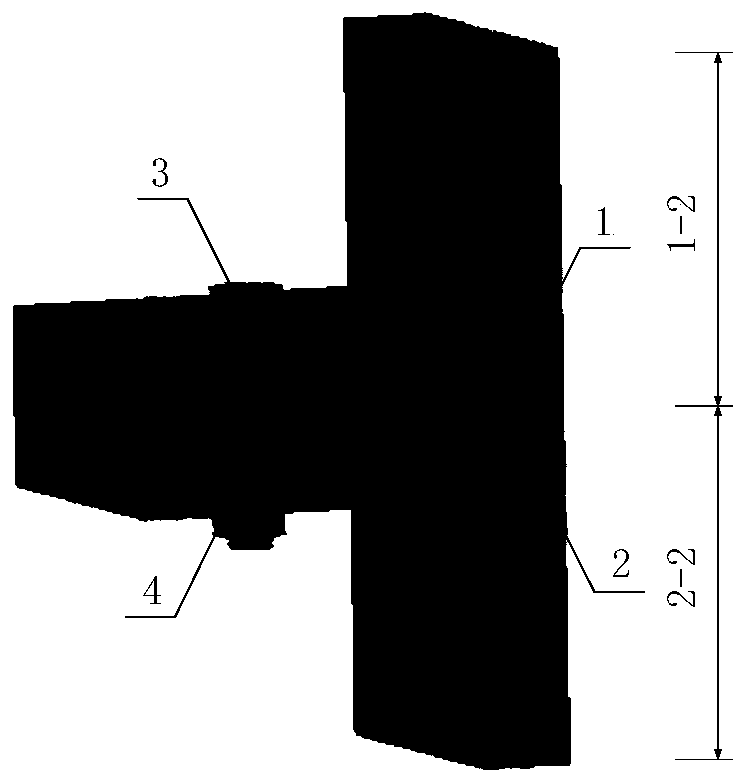

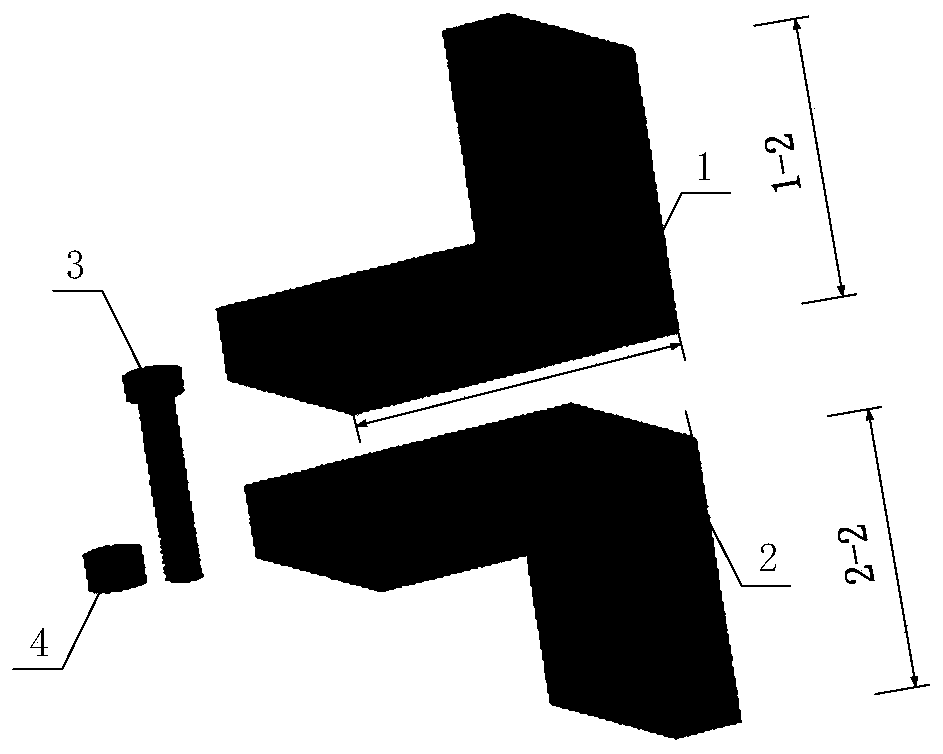

[0031] S1. First establish the 3D geometric model of the butt joint bolt connection structure of the cabin, such as Figures 1 to 3 As shown, the 3D geometric model includes the 3D geometric model of the connected part and the 3D geometric model of the bolted joint, and the connected part includes an upper connected plate (1) and a lower connected plate (2), both of which are L shaped plate, corresponding positions on its long sides (1-1) and (1-2) are respectively provided with circular holes of the same size to form through holes; the bolted connectors include screw rods (3) and nuts (4); The connected plate (1) is connected with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com