Optical lens module and forming method thereof

An optical lens and module technology, applied in the optical field, can solve problems such as damage to the collected objects, and achieve the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

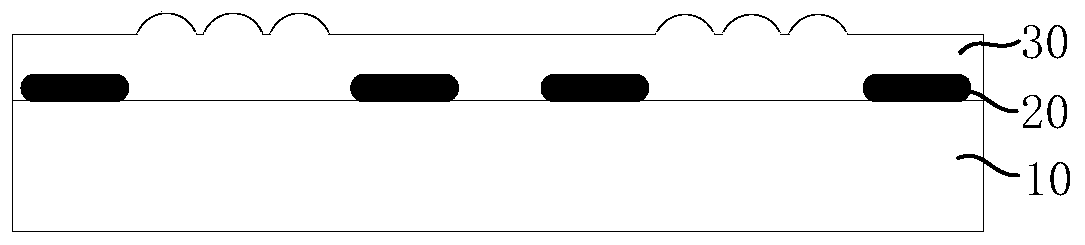

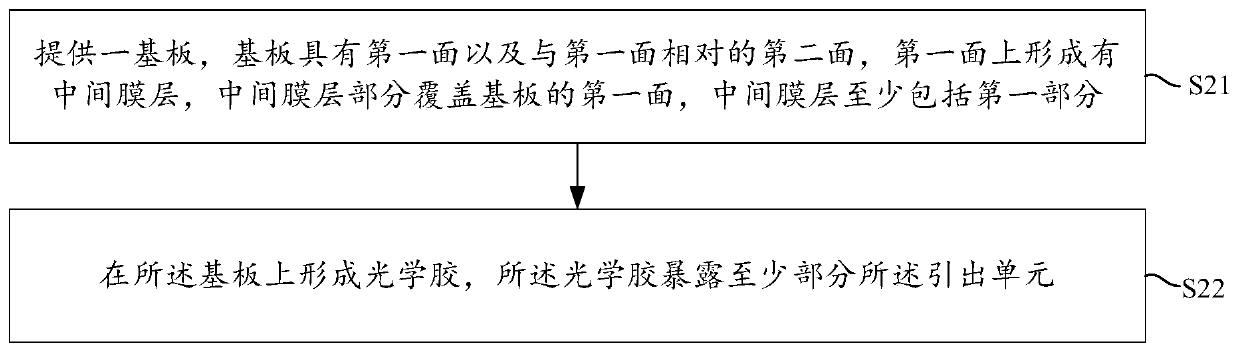

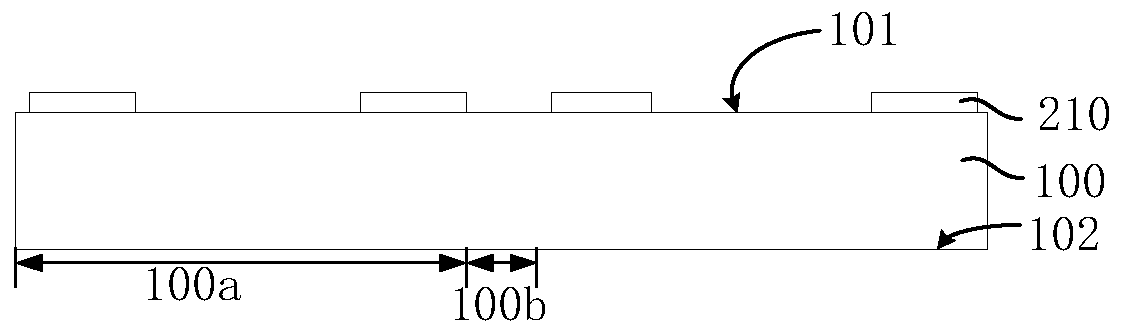

[0040] As described in the background art, there is a limitation in forming an ITO film on the side of the glass substrate facing away from the optical glue. Therefore, the inventors set the ITO film on the side of the glass substrate facing the optical glue and used the following method Prepare wafer-level optical lens (WLO), as follows: figure 1 As shown, first, a circular glass substrate 10 is provided. An ITO film layer is formed on the glass substrate 10, and the ITO film layer includes at least two ITO pads 20; then, on the glass substrate 10 The side with the ITO film layer is covered with a layer of optical glue 30; then, the optical glue 30 is pressed by a mold; then, the optical glue 30 is cured by UV (ultraviolet light) and / or thermally baked 30 Perform curing treatment; finally, remove the mold. Since all the optical lens modules of the wafer-level optical lens in the above process are prepared through an integrated molding process, the ITO film is completely confin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com