Printed circuit board component testing device

A printed circuit board and component testing technology, applied in printed circuit testing, electronic circuit testing, measuring devices, etc., can solve problems such as large elasticity, affecting test accuracy and reliability, and inconvenient testing of PCB components, so as to improve test efficiency, Stable test results and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

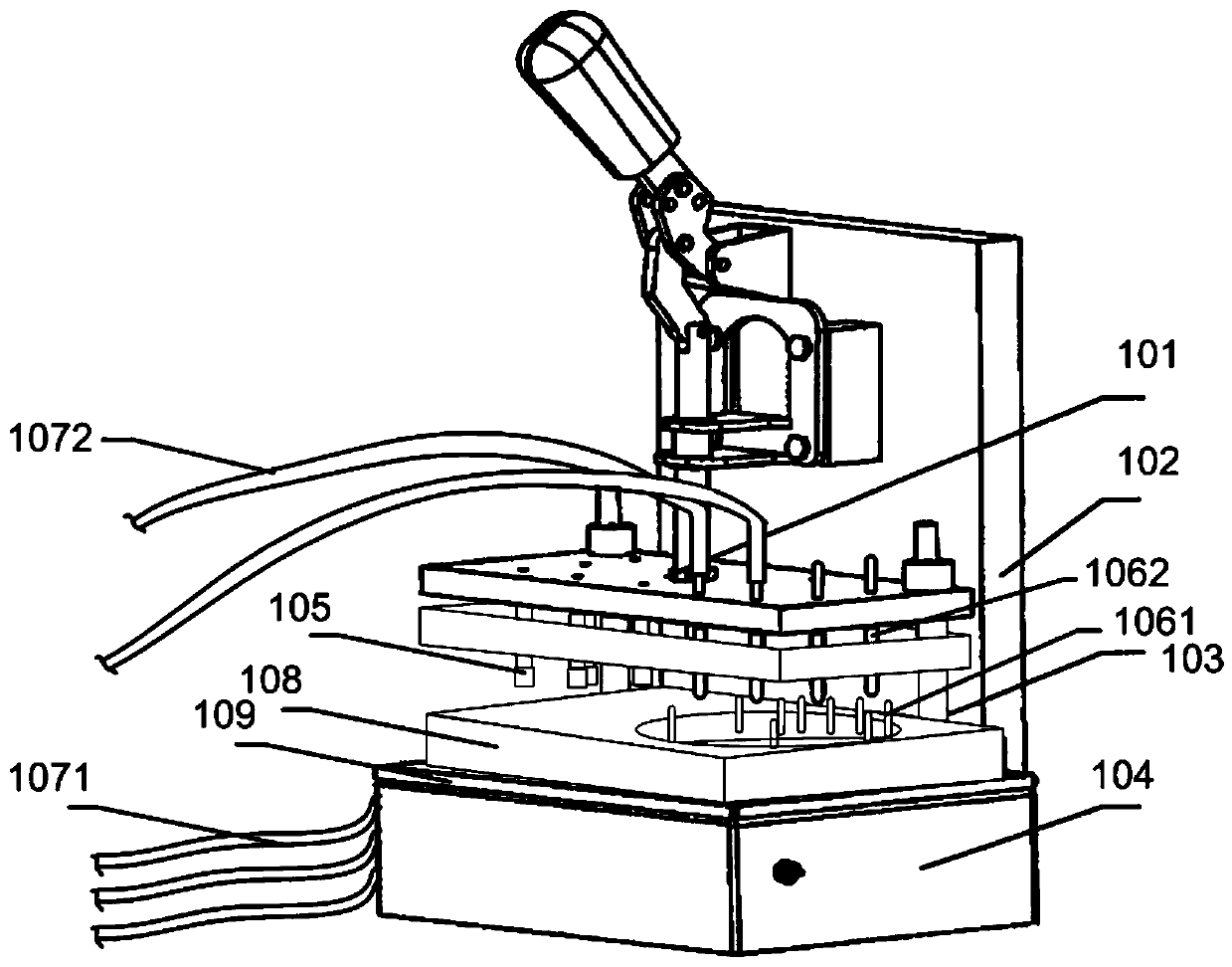

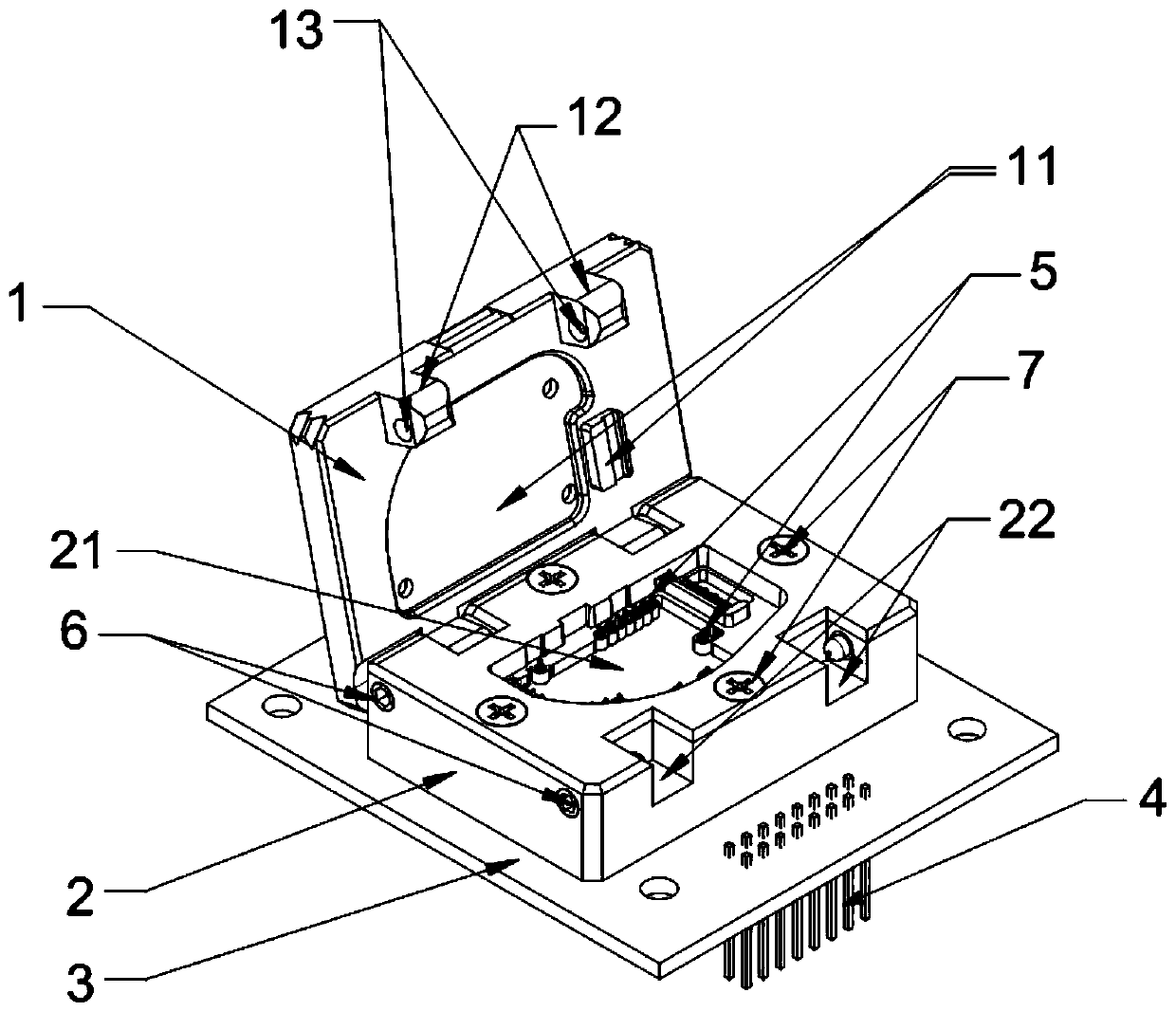

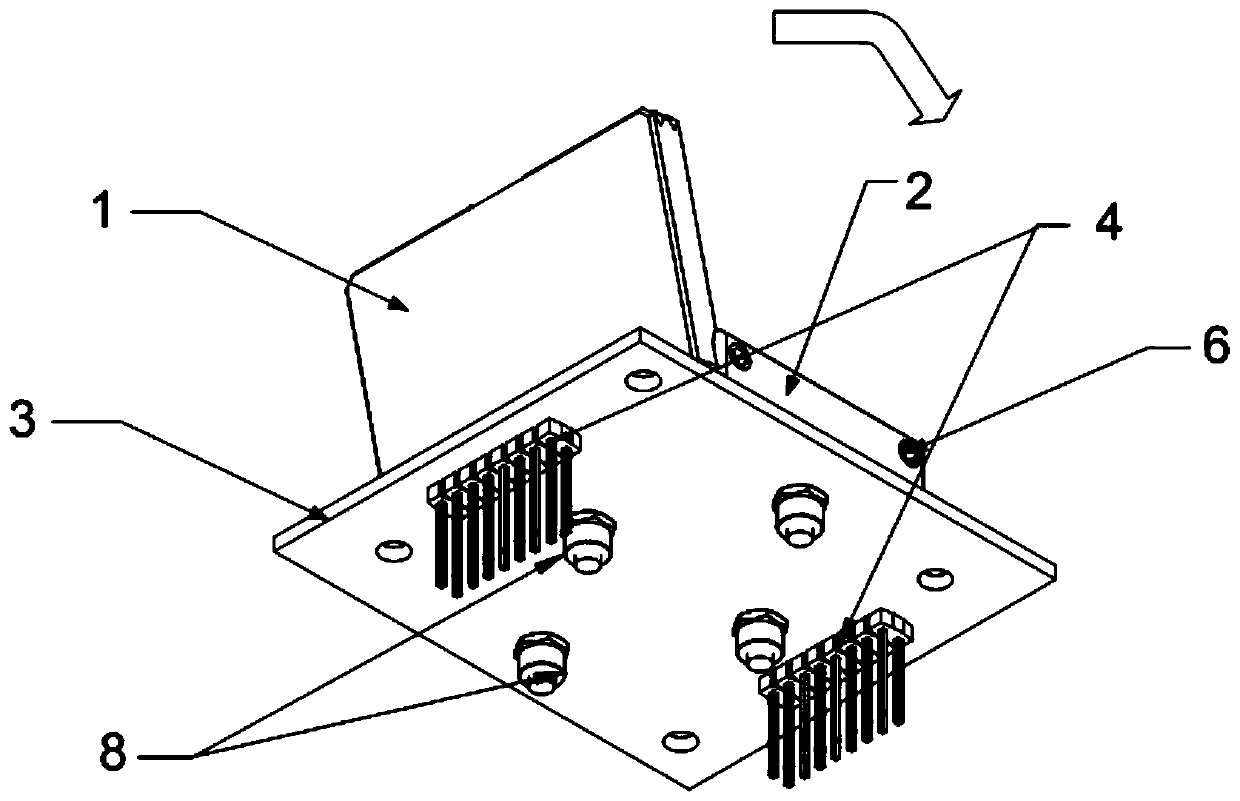

[0039] In order to make the purpose and features of the present invention more obvious and understandable, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0040] Please refer to Figure 2 to Figure 4 , an embodiment of the present invention provides a printed circuit board assembly testing device, including a cover 1 , a circuit board fixing base 2 , a carrier board 3 and a connector 4 which are sequentially fitted from top to bottom.

[0041] The connector 4 can be fixedly arranged on the side of the carrier board 3 facing away from the circuit board fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com