Coal series fault formation simulation test device and forward and reverse fault simulation test method

A simulation test and reverse fault technology, which is applied to lifting devices, measuring devices, teaching models, etc., can solve the problem that the simulation test equipment cannot simulate normal faults and reverse faults at the same time, and achieve the effect of easy operation and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

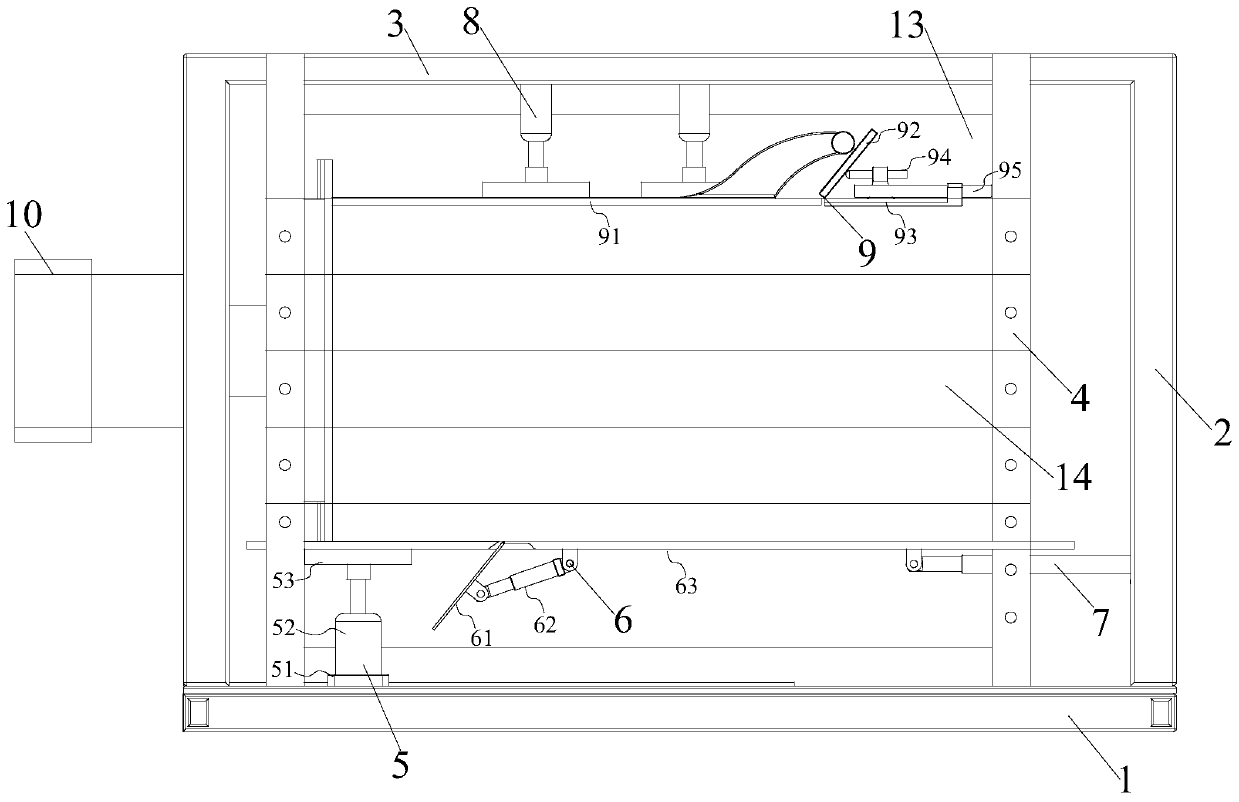

[0036] combine Figure 1 to Figure 5 As shown, a coal-measure fault formation simulation test device and a normal and reverse fault simulation test method provided by the present invention are specifically implemented as follows.

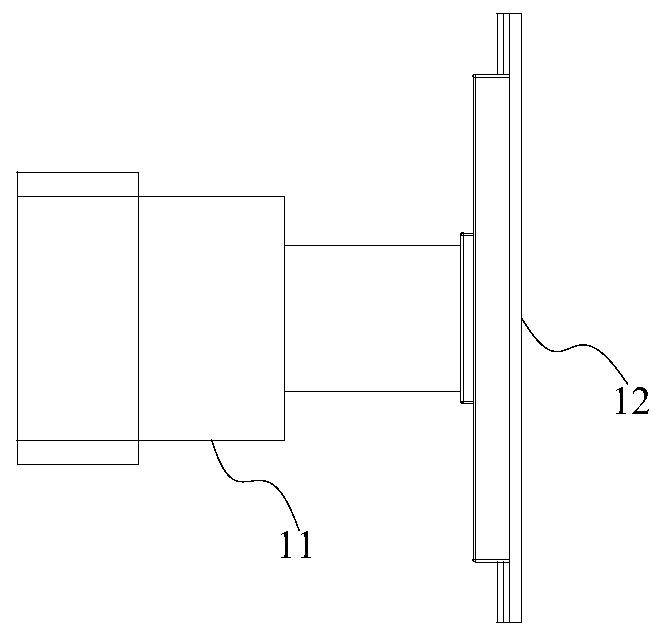

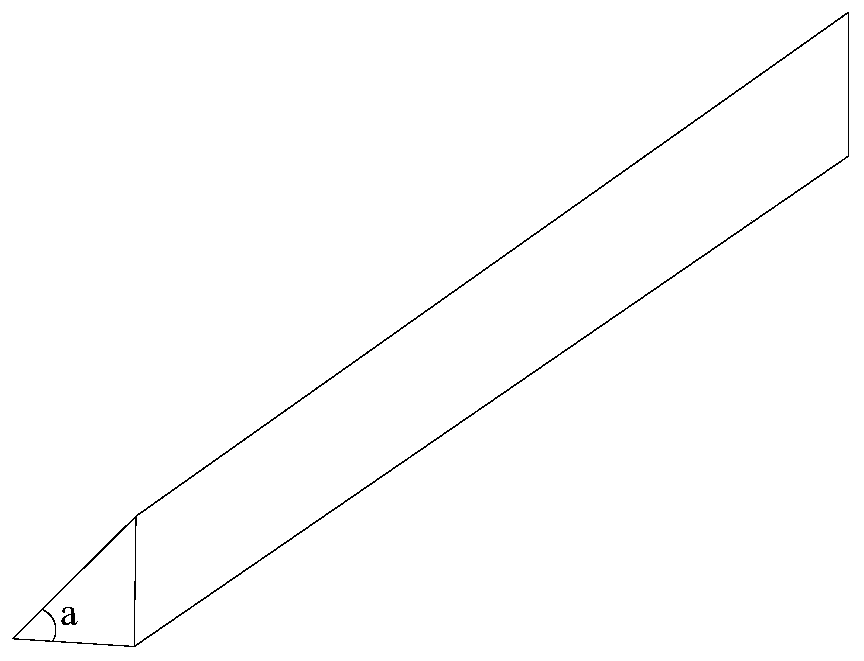

[0037] A coal-measure fault formation simulation test device specifically includes a base 1, a column 2, a top beam 3 and a baffle 4, wherein the two ends of the base 1 are provided with columns 2, and the base 1 between the columns 2 is also provided with a baffle 4 , the upper end of the column 2 is connected by the top beam 3 , and the experimental body 14 is placed between the baffles 4 . In addition, the test device also includes a hydraulic lifting device 5 , a lower angle adjustment device 6 , a push rod device 7 , an upper loading device 8 , an upper angle adjustment device 9 , a side loading device 10 and a transparent side plate 13 . The hydraulic lifting device 5 is lifted to adapt to the height change of one side of the test body during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com