Combustion stove for mating with incinerator

A technology for incinerators and combustion stoves, applied in incinerators, burners, combustion methods, etc., can solve the problems of re-ignition, black smoke and flameout of combustible gas, and inability to fully burn the incinerator, so as to reduce the outflow of flue gas. , the effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

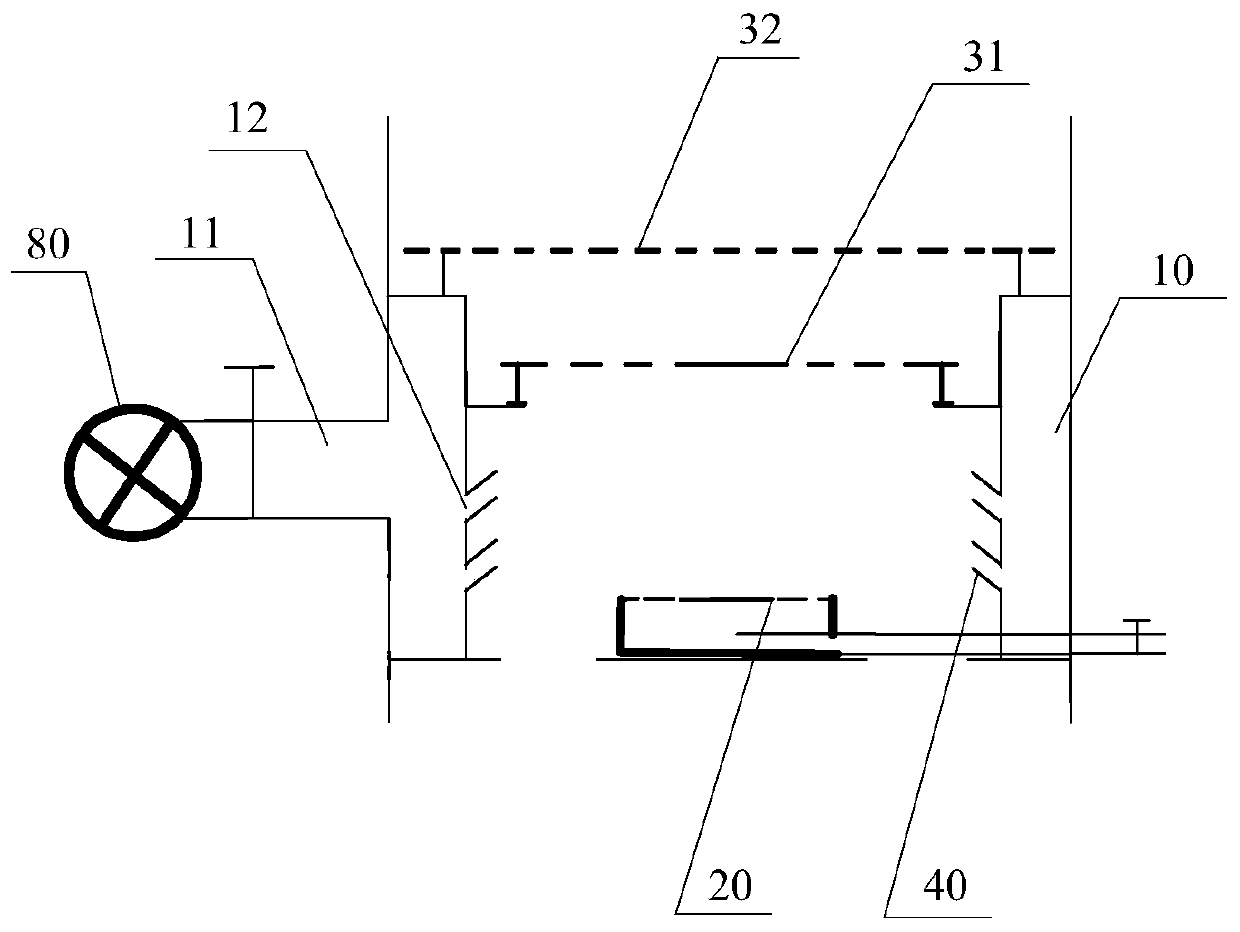

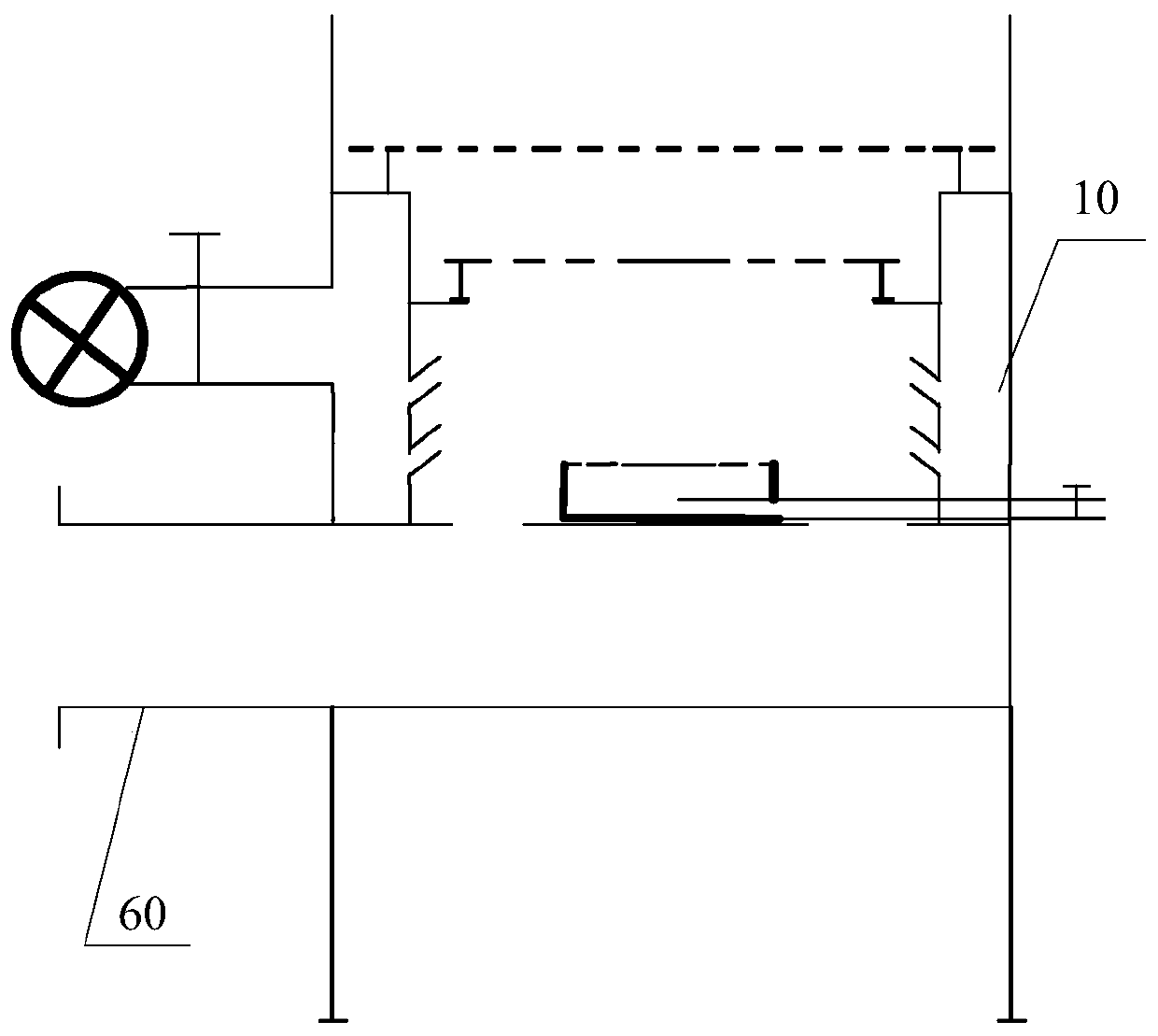

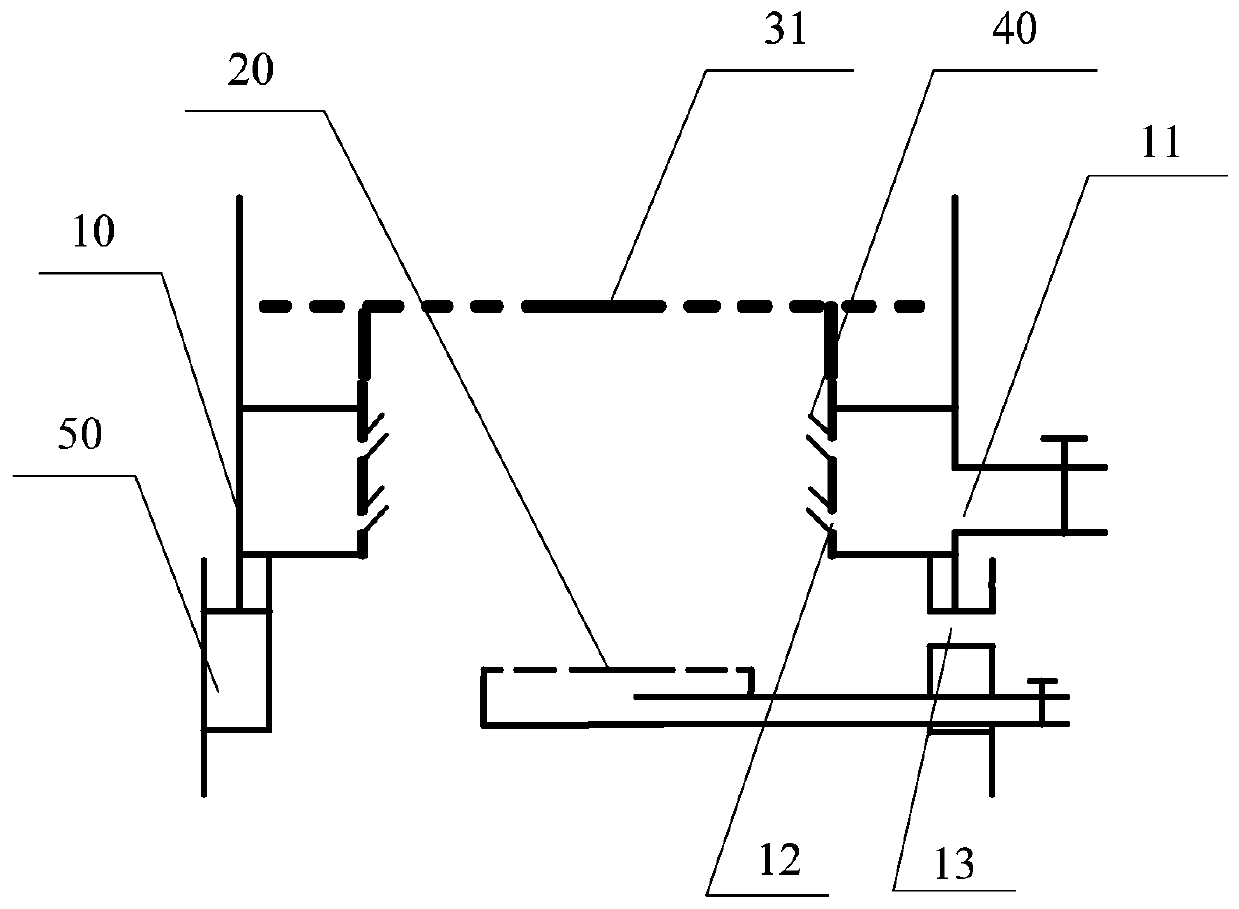

[0029] refer to figure 1 , a preferred embodiment of the present invention provides a combustion stove for an incinerator, which is used in conjunction with an incinerator to burn the combustible gas produced by the gasification and cracking of garbage in the incinerator. In this embodiment, the combustible gas includes Gasification gas produced by garbage gasification and pyrolysis gas produced by garbage cracking. The combustion stove includes a stove body 10 with openings at both ends, and the stove body 10 includes an air intake end connected with an incinerator, and a flame injection end for emitting fire. The stove body 10 is also provided with a gas supply channel and an air induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com