Positioning structure for mandrel assembly parts, use method thereof, and impeller dynamic balance testing device

A technology for positioning structures and positioning methods, applied in static/dynamic balance testing, machine/structural component testing, measuring devices, etc., can solve problems such as inability to locate assembly parts, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

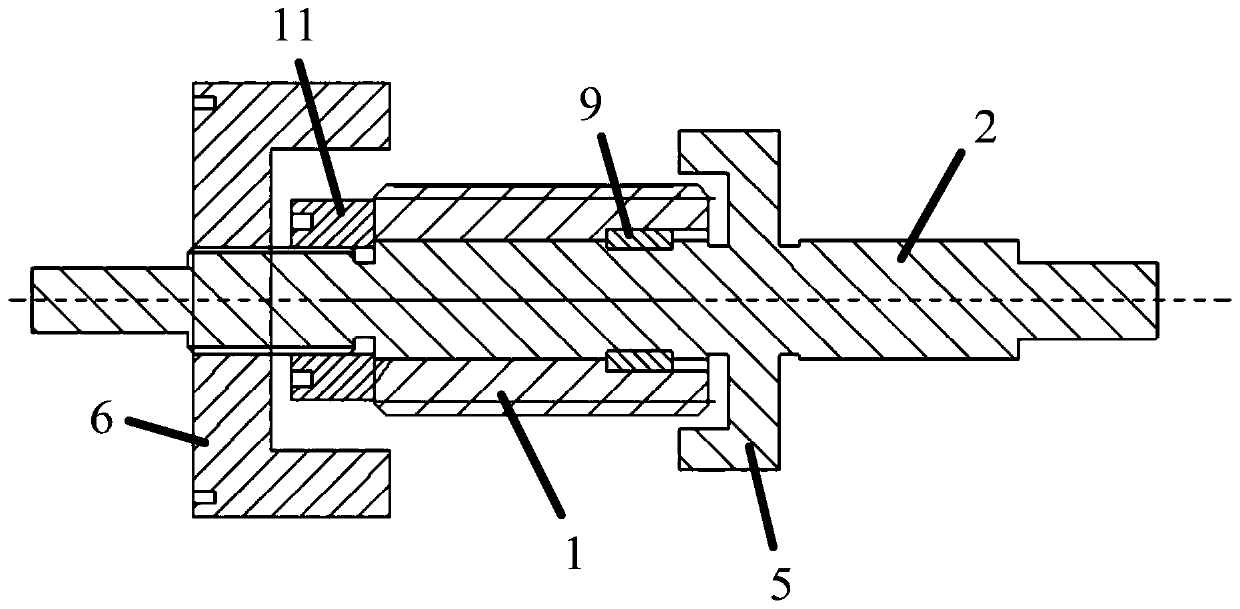

[0054] This embodiment provides an impeller dynamic balance test device, such as Figure 9 shown, which includes:

[0055] mandrel 2;

[0056] In the positioning structure of the mandrel assembly, the impeller is sleeved on the outer surface of the positioning sleeve 1 of the positioning structure of the mandrel assembly, and the first positioning member 5 and the second positioning member 6 are connected to the two ends of the impeller respectively. Such as figure 1 As shown, the positioning structure of the mandrel assembly includes:

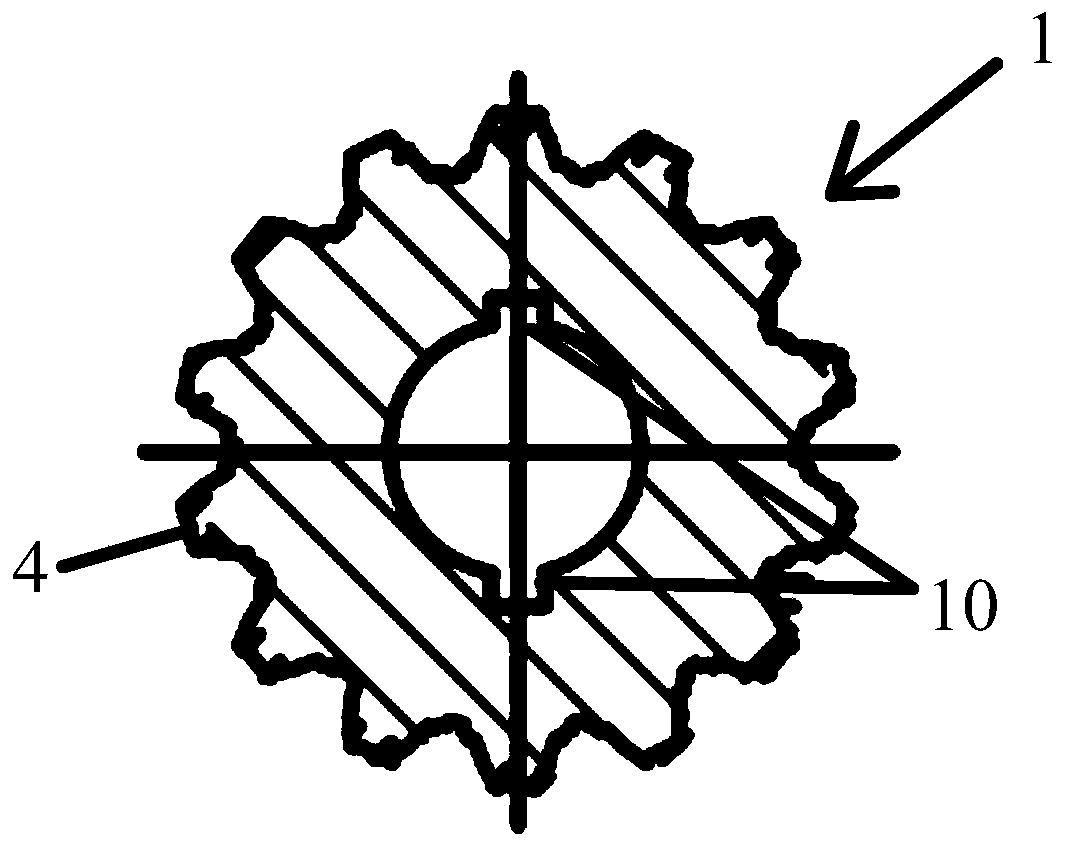

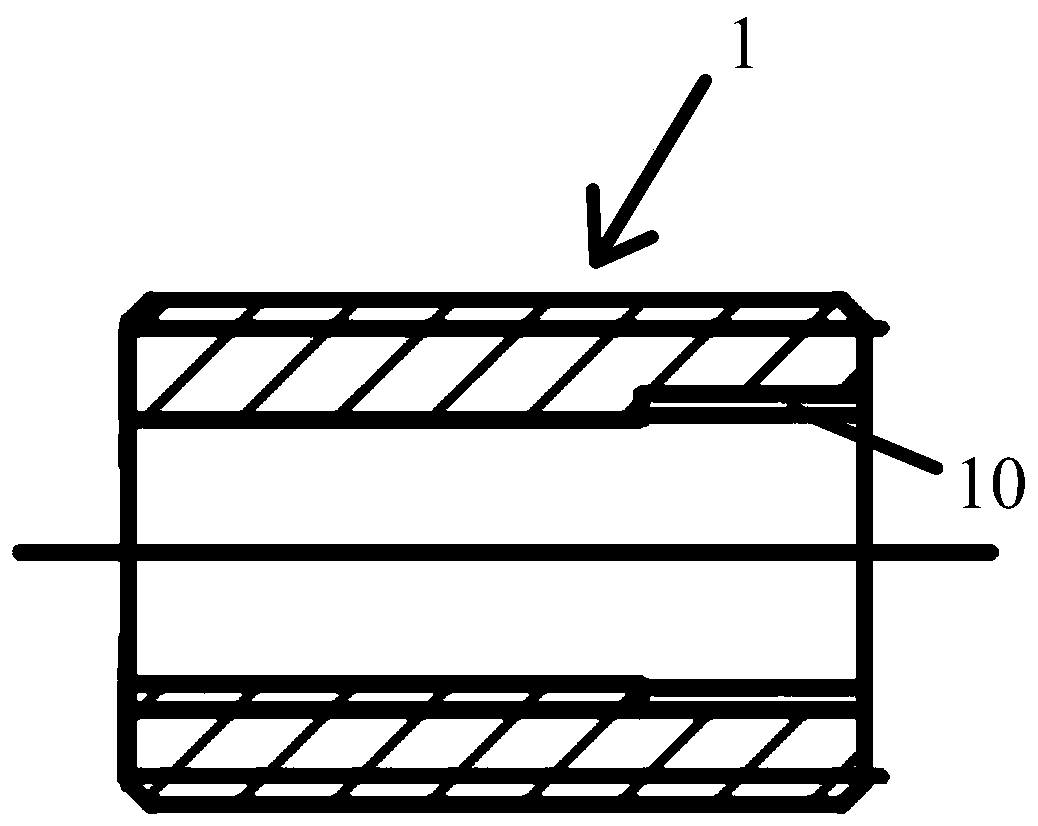

[0057] Locating sleeve 1, such as figure 2 with image 3 As shown, the positioning sleeve 1 is a spline sleeve, and the positioning sleeve 1 and the mandrel 2 are installed together through the flat key 9, and the impeller is installed on the mandrel 2 through the positioning sleeve 1, so that the user can adjust the impeller according to the size of the impeller. By selecting positioning sleeves with different diameters, impellers with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com