Method for monitoring and controlling clearance between wind power generator unit blade and tower drum

A technology of wind turbines and control methods, which is applied in the monitoring of wind turbines, control of wind turbines, and wind power generation. risk, reduced risk of collision, effects of significant practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

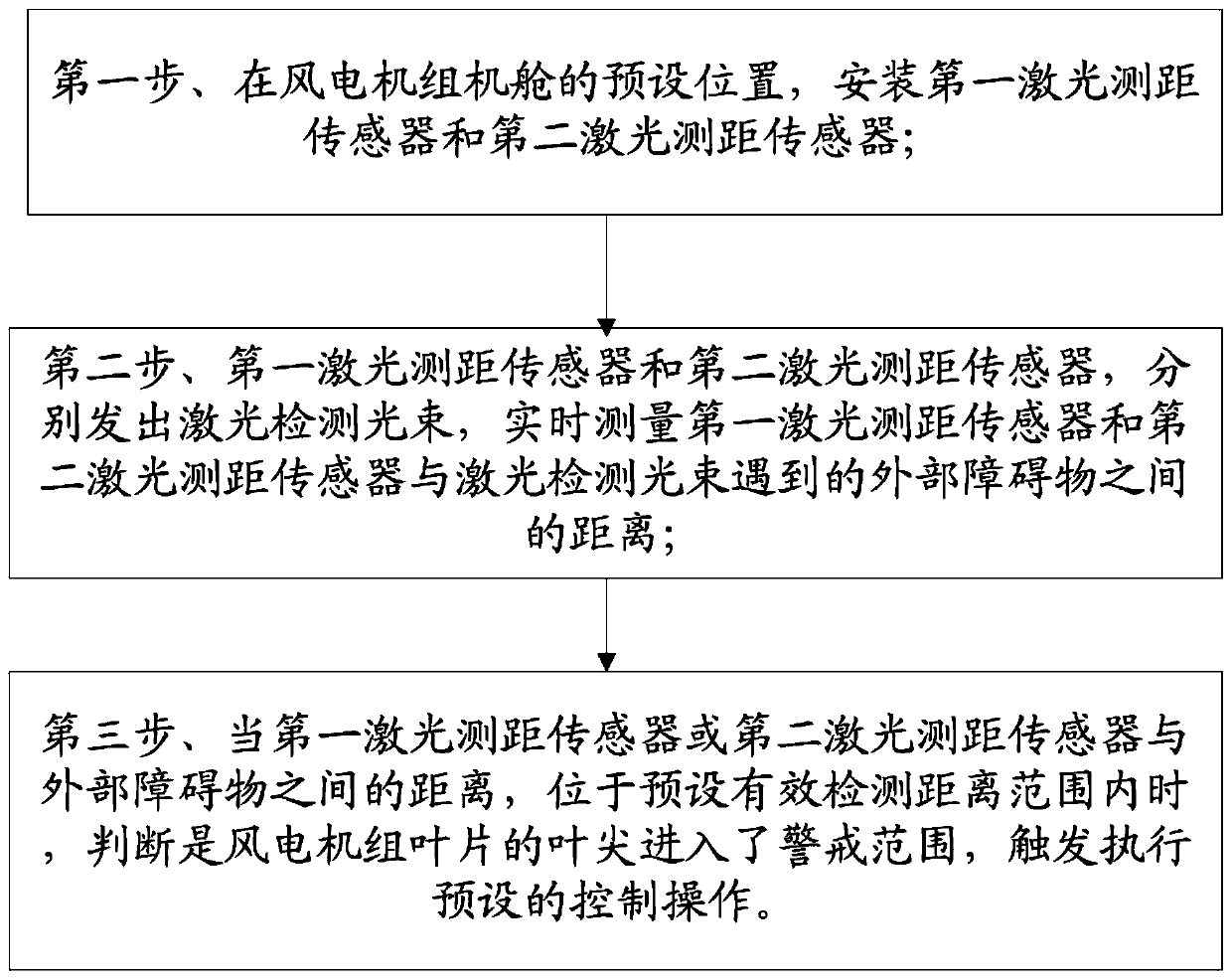

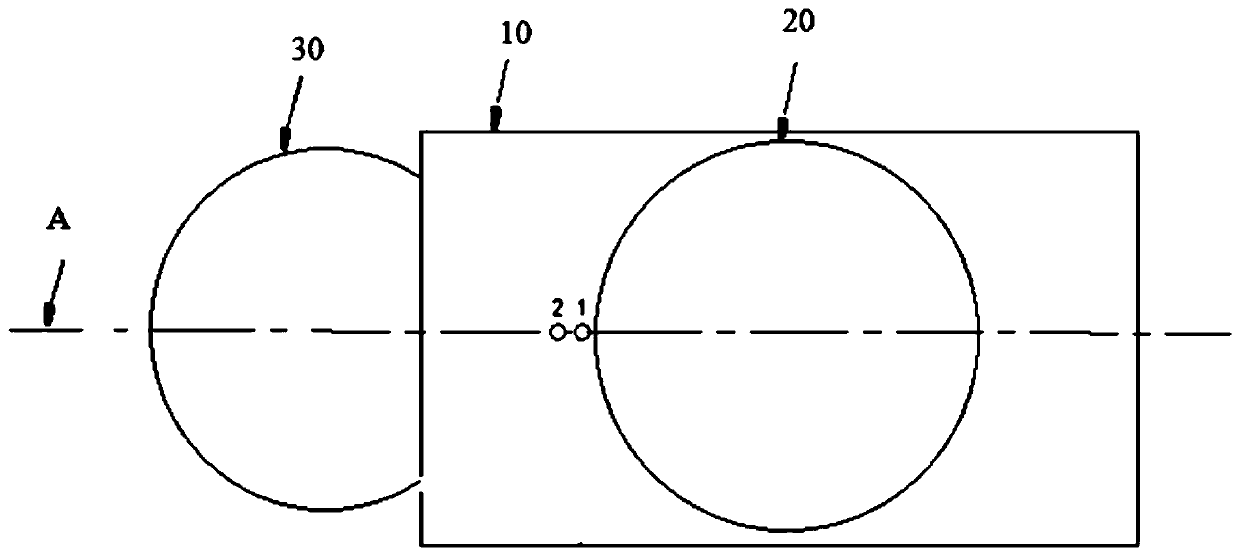

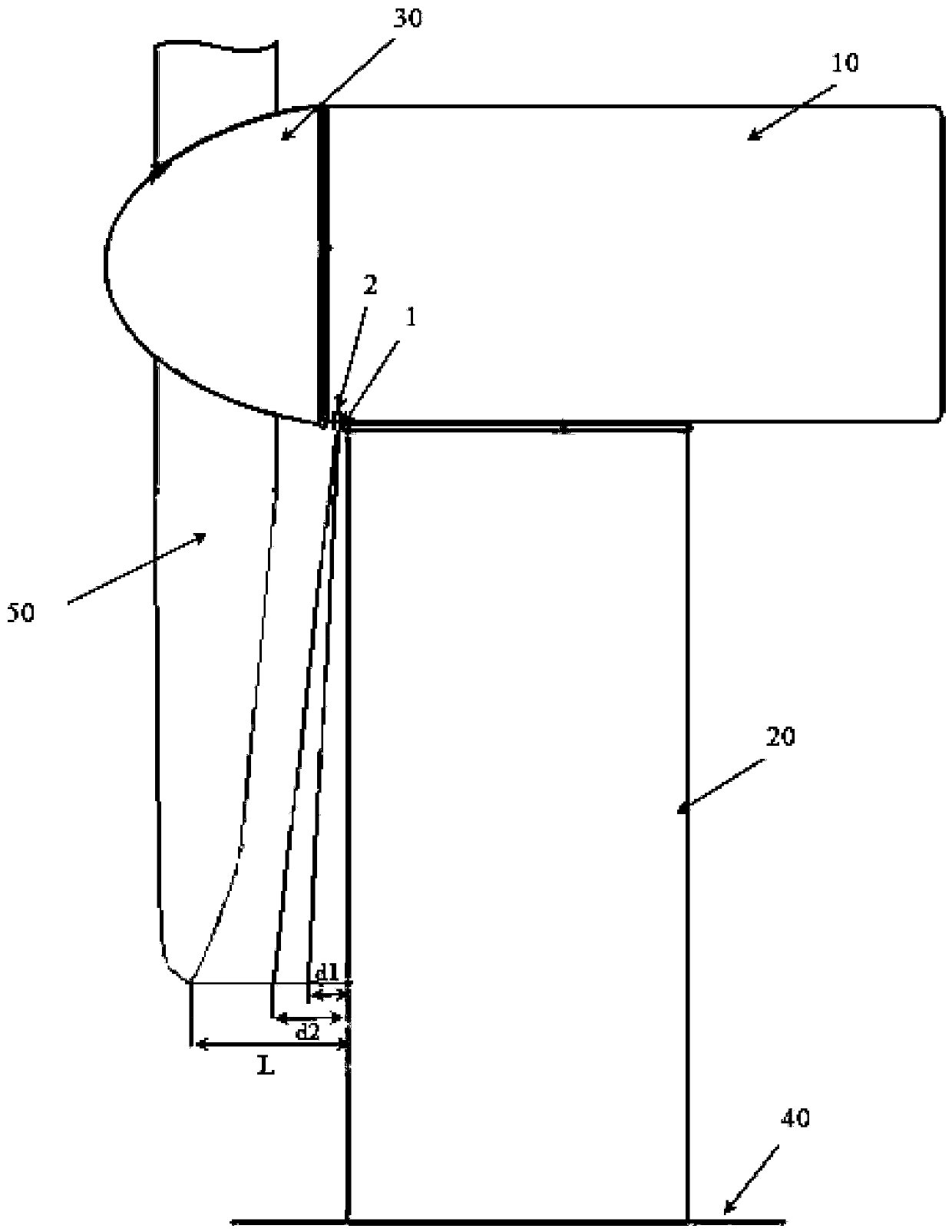

[0034] see Figure 1 to Figure 4 , the invention provides a method for monitoring and controlling the clearance between blades and towers of wind turbines, comprising the following steps:

[0035] The first step is to install the first laser ranging sensor and the second laser ranging sensor at the preset position of the wind turbine nacelle;

[0036] In the second step, the first laser ranging sensor and the second laser ranging sensor emit laser detection beams respectively, and measure the distance between the first laser ranging sensor, the second laser ranging sensor and the external obstacle encountered by the laser detecting beam in real time. the distance between

[0037] Step 3. When the distance between the first laser ranging se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com