Earth-rock dam composite core wall structure and construction method thereof

A construction method and technology for earth-rock dams, applied in dams, barrages, wall dams, etc., can solve problems such as a large number of additional resources of the anti-seepage system, affecting the safe operation of dams, and core wall defects, and reduce engineering investment and operating costs. , Improve stability and durability, improve the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The basic core wall in this embodiment is an asphalt concrete core wall 21 .

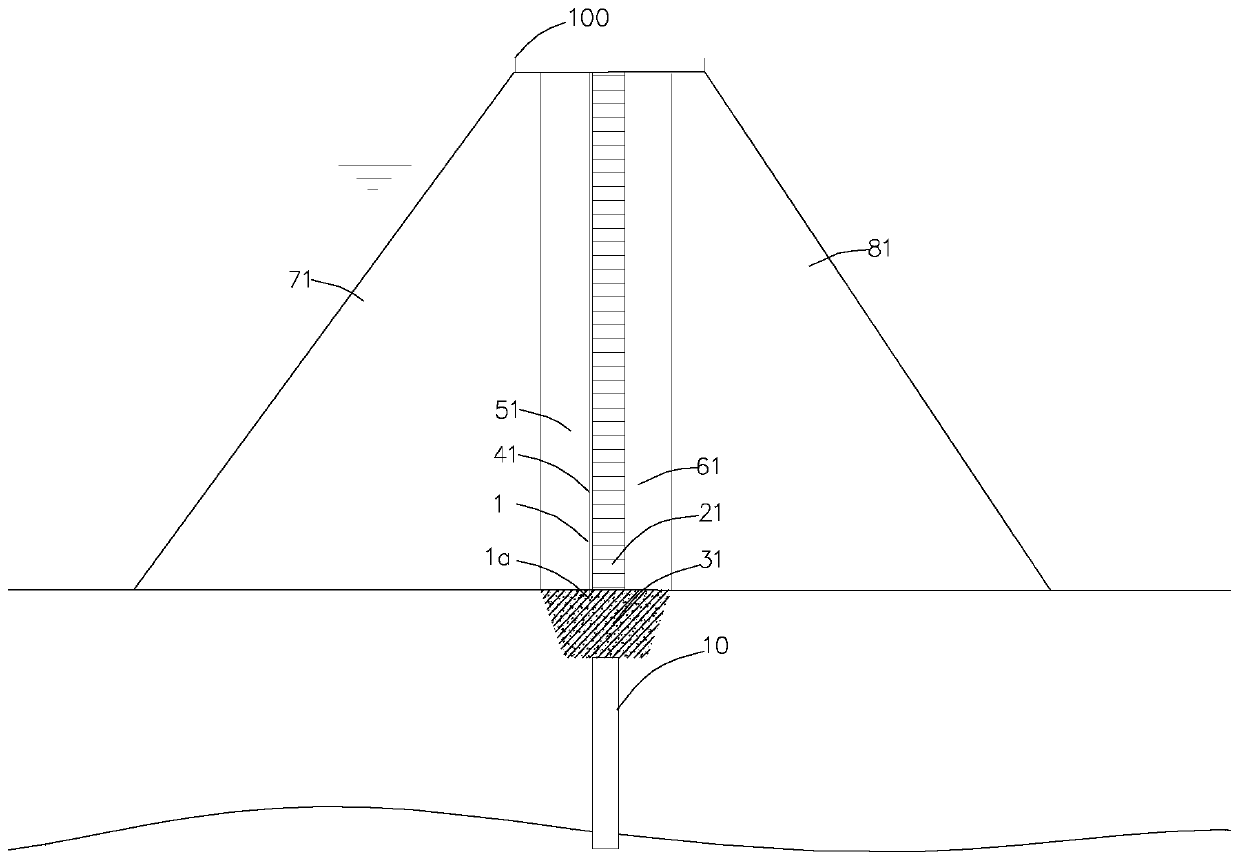

[0031] Such as figure 1 As shown, this embodiment provides an earth-rock dam HDPE membrane and asphalt concrete composite core wall structure, including: an asphalt concrete core wall 21 filled in the middle; an HDPE membrane 1 closely attached to the upstream surface of the asphalt concrete core wall 21 .

[0032] Wherein, in this embodiment, the cationic asphalt paint coating 41 is applied on the downstream surface of the HDPE diaphragm 1 to achieve close adhesion with the asphalt concrete core wall 21 . And the HDPE diaphragm 1 of this embodiment adopts the HDPE diaphragm with enhanced heat resistance.

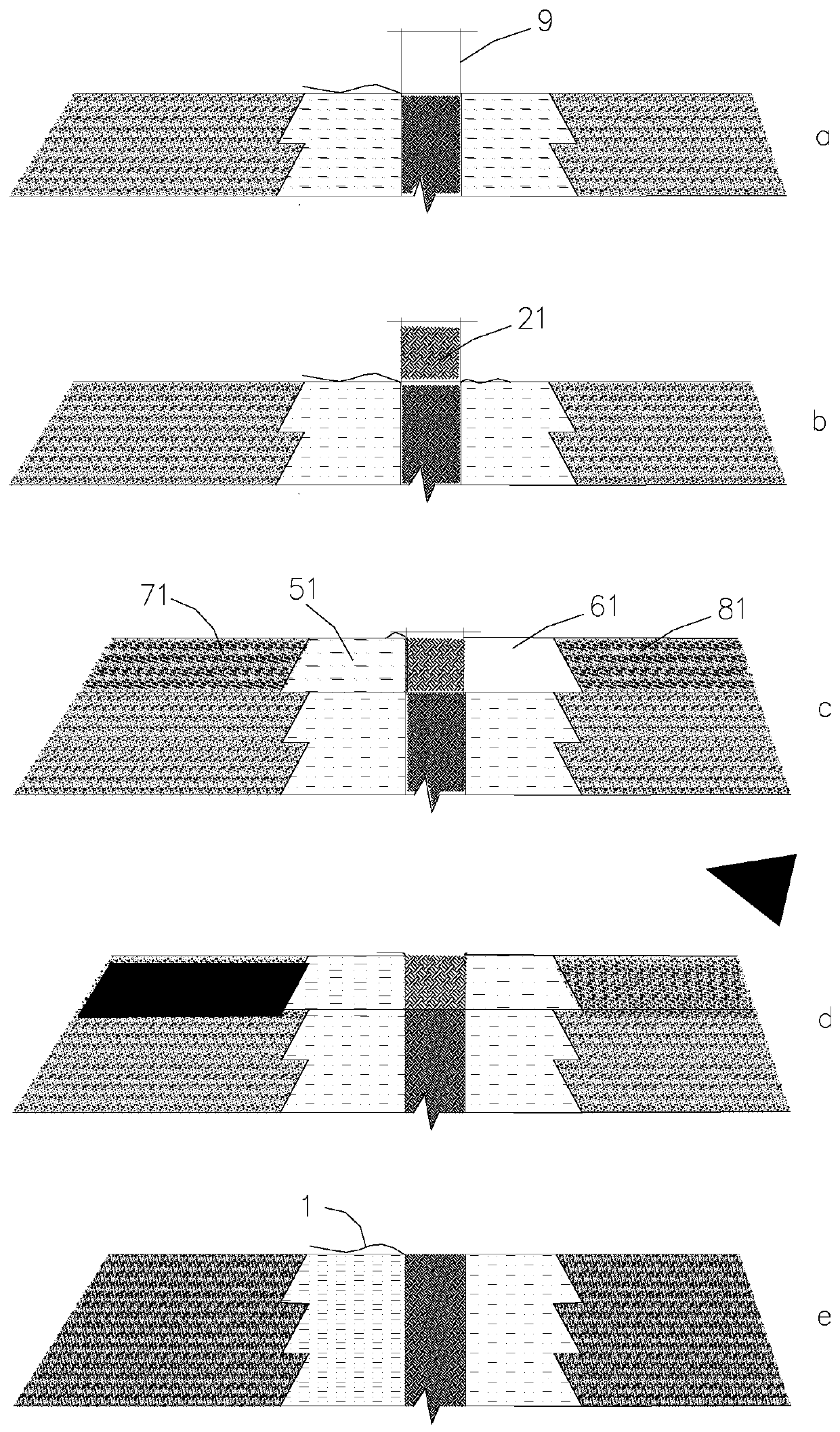

[0033] Present embodiment also provides a kind of construction method of HDPE film and asphalt concrete composite core wall, comprising:

[0034] 1. In the design stage, calculate and check the HDPE membrane and asphalt concrete core wall earth-rock dam structure to form the design draw...

Embodiment 2

[0052] The basic core of this embodiment is a clay core 22 .

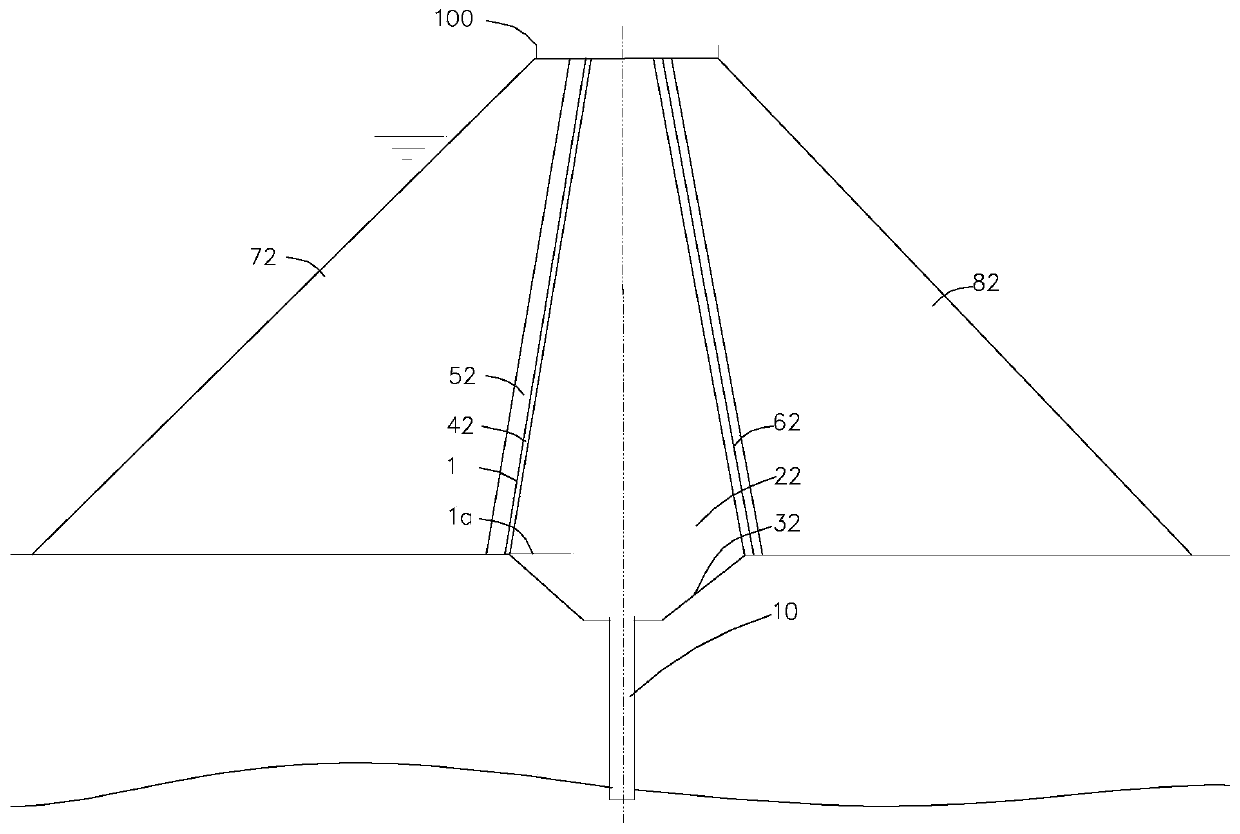

[0053] Such as image 3 As shown, this embodiment provides an HDPE membrane and clay composite core wall structure for an earth-rock dam, including: a clay core wall 22 filled in the middle; and an HDPE membrane 1 tightly attached to the upstream surface of the clay core wall 22 .

[0054] Wherein, in this embodiment, the clay slurry coating 42 is applied on the downstream surface of the HDPE diaphragm 1 to achieve close adhesion with the clay core wall 22 . The HDPE diaphragm 1 of this embodiment adopts a standard HDPE diaphragm.

[0055] Present embodiment also provides a kind of construction method of HDPE film and clay composite core wall, comprising:

[0056] 1. In the design stage, calculate and check the HDPE membrane and clay core earth-rock dam structure to form the design drawing of the dam;

[0057] During the construction stage, the foundation is excavated and anti-seepage treated, and the clay core ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap