A fabric forming device with oblique yarn guiding function

A guiding function and forming device technology, which is applied in textiles, looms, textiles and papermaking, etc., can solve the problems of insufficient mechanical properties of composite materials and easy adhesion of fabrics, so as to reduce the adhesion effect, wide engineering application range, and easy disassembly and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further disclose the invention content, features and effects of the present invention, the following examples are specifically cited and described in detail in conjunction with the accompanying drawings as follows.

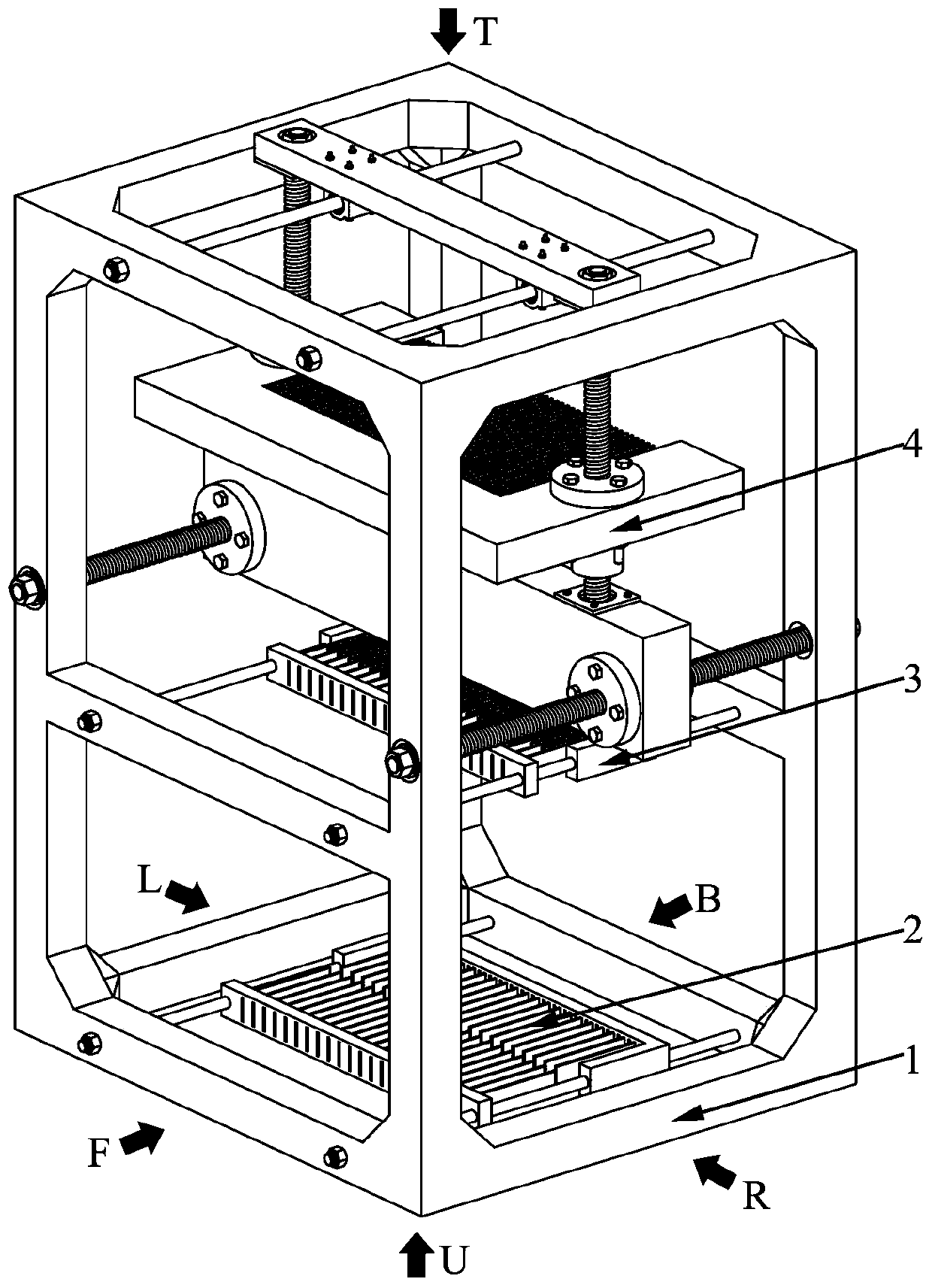

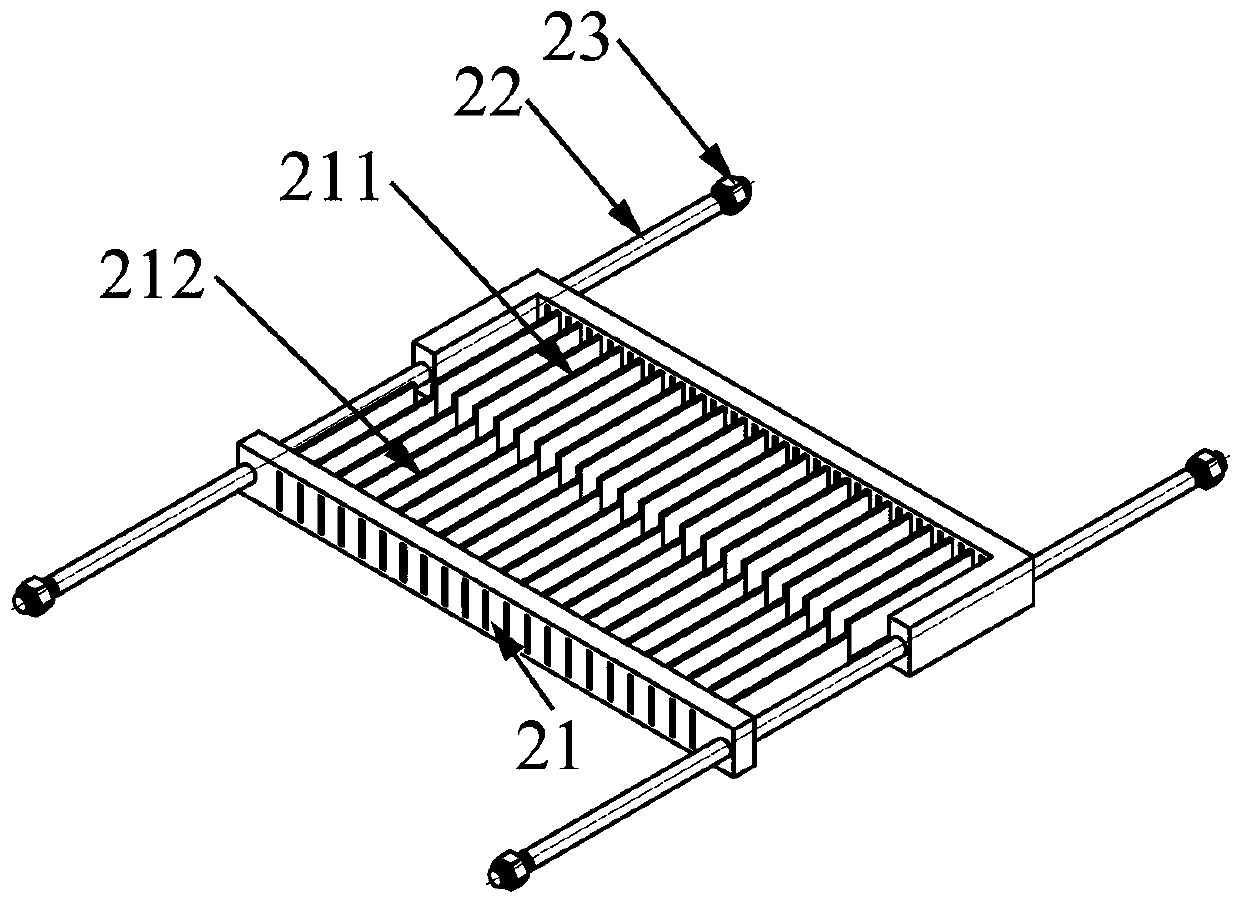

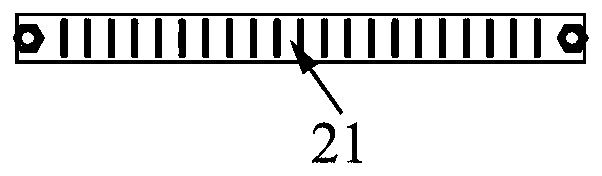

[0050] See attached Figure 1-23 , a fabric forming device with an oblique yarn guiding function, comprising a frame 1, a yarn drawing mechanism 2, a yarn dividing mechanism 3 and a weft beating mechanism 4, the yarn drawing mechanism 2, the yarn dividing mechanism 3, and a weft beating mechanism 4 are installed in the lower, middle and upper parts of the frame 1 in turn; the yarn drawing mechanism 2 includes a movable reed 21, a double-headed long bolt A22, and a fastening nut A23, and the movable reed 21 includes a half-open and The main reed 211 with reed beams on both sides and the auxiliary reed 212 with half openings and no reed beams on both sides, the reed teeth of the auxiliary reed 212 are relatively embedded in the grooves between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com