A functional ordered mesoporous polymer material and its preparation method and application

A polymer material and functionalization technology, applied in the field of materials, can solve problems such as narrow application range, and achieve the effects of low cost, fast response speed, good industrial production and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

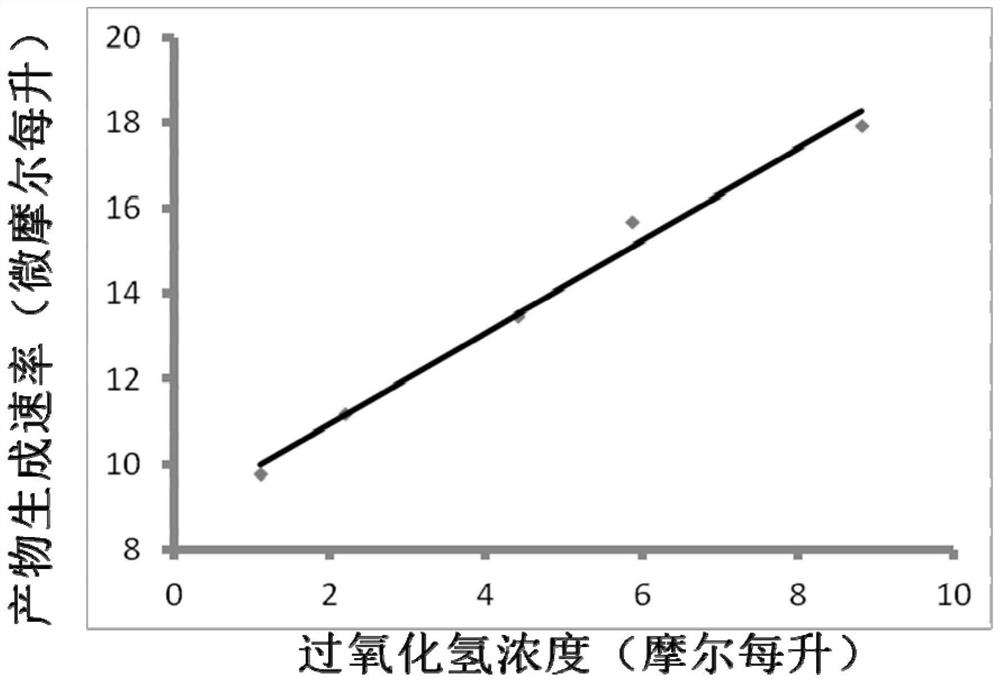

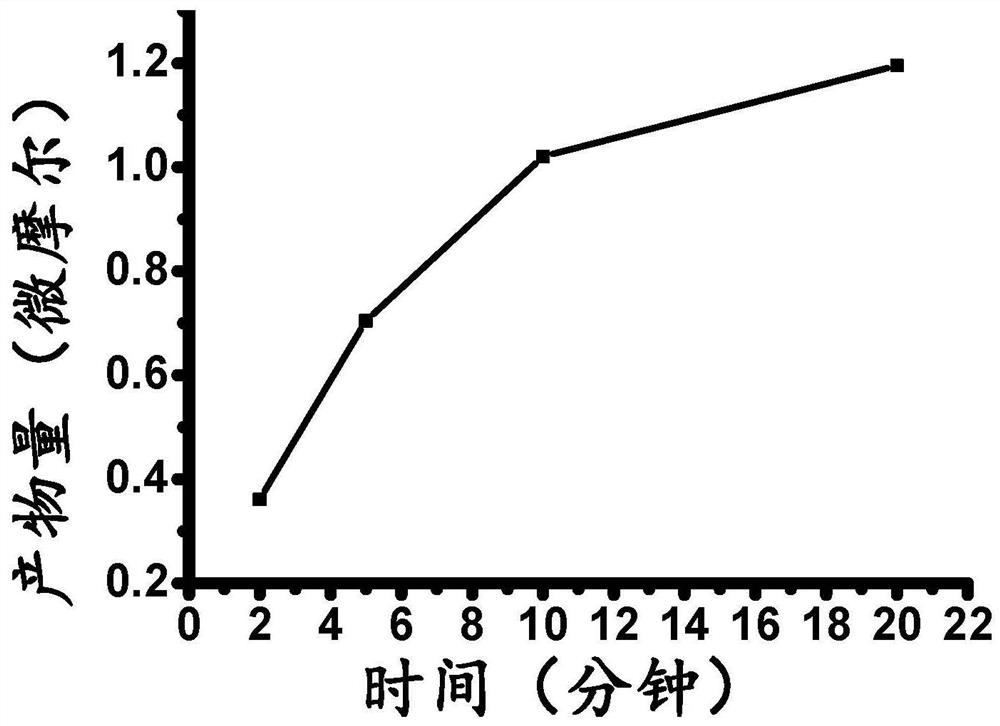

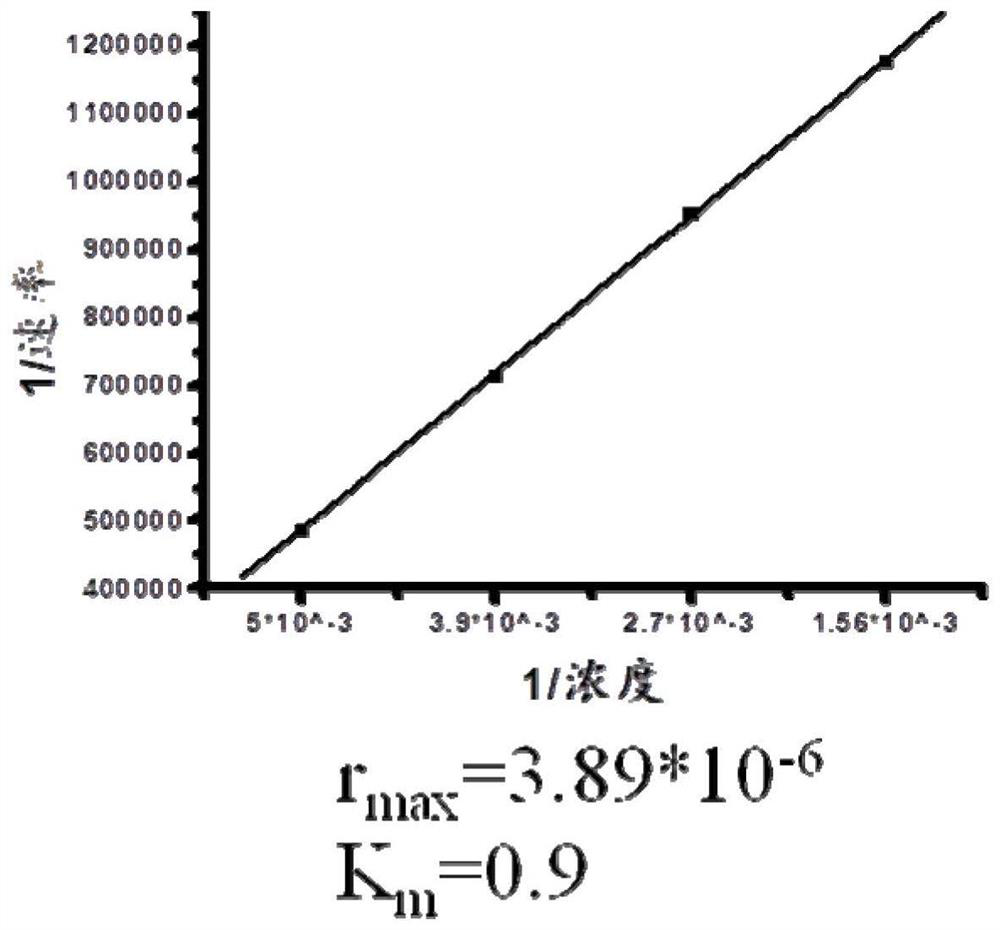

Embodiment 1

[0030] At 40°C, 1.5g F127(EO 106 PO 70 EO 106 ) was dissolved in 8.00g absolute ethanol and 1.00g water, stirred for 1h; 1.92g TiCl 4 Hydrolyze in 7.50 g of absolute ethanol and 0.50 g of water for 30 min; mix the two solutions, add 5 g of nitrogen source-modified soluble resole phenolic resin, and stir at 40 ° C for 2 h. Then spread the mixture evenly on the petri dish, and place it at room temperature for 24 hours to evaporate the organic solvent; finally transfer it to an oven at 100° C., and obtain the enzyme-loaded carrier after 24 hours. 200 mg of the obtained carrier was immersed in a 1 mg / mL cytochrome C solution, shaken for 24 hours, filtered, freeze-dried, and stored at -20°C. The obtained catalyst was used for the oxidation reaction of pyrogallol. Specific tests such as Figure 1-6 As shown, compared with the reaction catalyzed by free enzyme, the reaction rate of immobilized enzyme is about 2 times. And the immobilized enzyme generated 7.2μM product within 2m...

Embodiment 2

[0032] At 40°C, dissolve 1.5g F127 in 8.00g absolute ethanol and 1.00g water, stir for 1h; 1.92g TiCl 4Hydrolyze in 7.50 g of absolute ethanol and 0.50 g of water for 30 min; mix the two solutions, add 5 g of nitrogen source-modified soluble resole phenolic resin, and stir at 40 ° C for 2 h. Then spread the mixture evenly on the petri dish, and place it at room temperature for 24 hours to evaporate the organic solvent; finally transfer it to an oven at 100° C., and obtain the enzyme-loaded carrier after 24 hours. 200 mg of the obtained carrier was immersed in a 0.5 mg / mL hemoglobin solution, shaken for 24 hours, filtered, freeze-dried, and stored at -20°C. The obtained catalyst was used for the oxidation reaction of 4-AAP.

Embodiment 3

[0034] A method for preparing a functional ordered mesoporous polymer material, comprising the following steps: dissolving a nonionic surfactant in a mixed solution of water and an organic solvent to obtain a solution A, and mixing the solution A with a hydrolyzed titanium source , and add nitrogen source modified soluble resin for reaction, then volatilize water and organic solvent to obtain prepolymer; heat-cure the obtained prepolymer at low temperature, then immerse in enzyme solution for enzyme loading, and obtain functionalized organic ordered mesoporous polymer materials.

[0035] Among them, the nonionic surfactant adopts C 12 h 25 EO 23 , the mass concentration of nonionic surfactant is 0.5%, the reaction temperature is 15°C, and the reaction time is 4h; the titanium source is titanium tetrachloride; the nitrogen source is urea; the organic solvent is tetrahydrofuran; the soluble resin is phenolic resin; the enzyme solution The middle enzyme is cytochrome C. The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com