Precipitation adsorption purification device for treatment of dye wastewater

A technology of dye wastewater, precipitation and adsorption, which is applied in textile industry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as the complex structure of backwashing devices, and achieve convenient, fast and convenient backwashing process The effect of adsorption structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

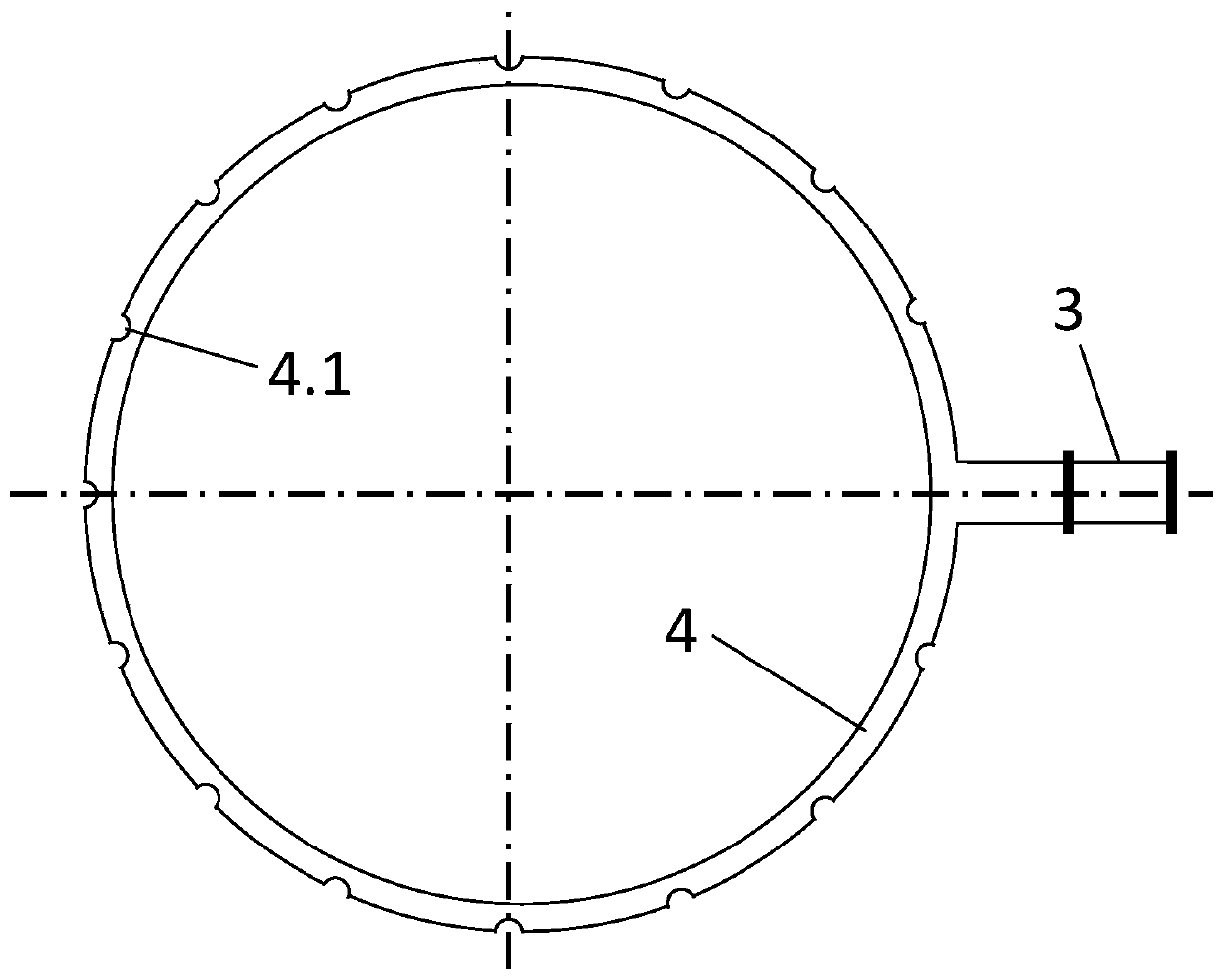

[0029] The invention provides a kind of precipitation adsorption purification device (abbreviation device, see Figure 1-10 ), characterized in that the device includes a tank body 1, an annular water distribution pipe 4, a slow-flow filter structure 6, an adsorption purification structure 8, a drain pipe 9, an upper support plate 13, a secondary sedimentation chamber check valve 14, and a state conversion mechanism 15. State conversion conduit 16, lower support plate 17, one-way valve 18 of the first-stage sedimentation chamber, lower support plate connecting plate 19, upper gasket 20 and lower gasket 21;

[0030] The bottom of the inside of the tank body 1 is fixed with a lower supporting plate connecting plate 19, and the lower supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com