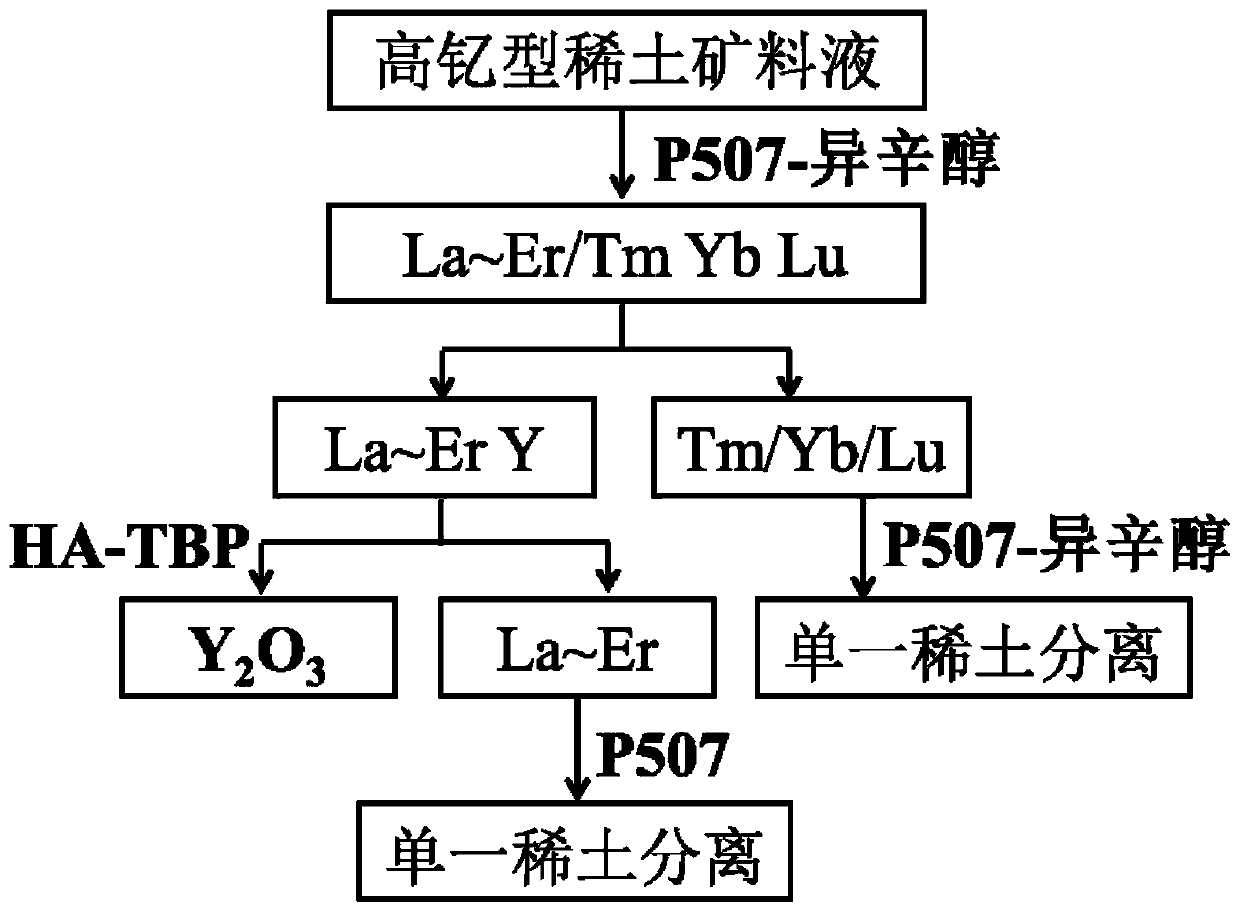

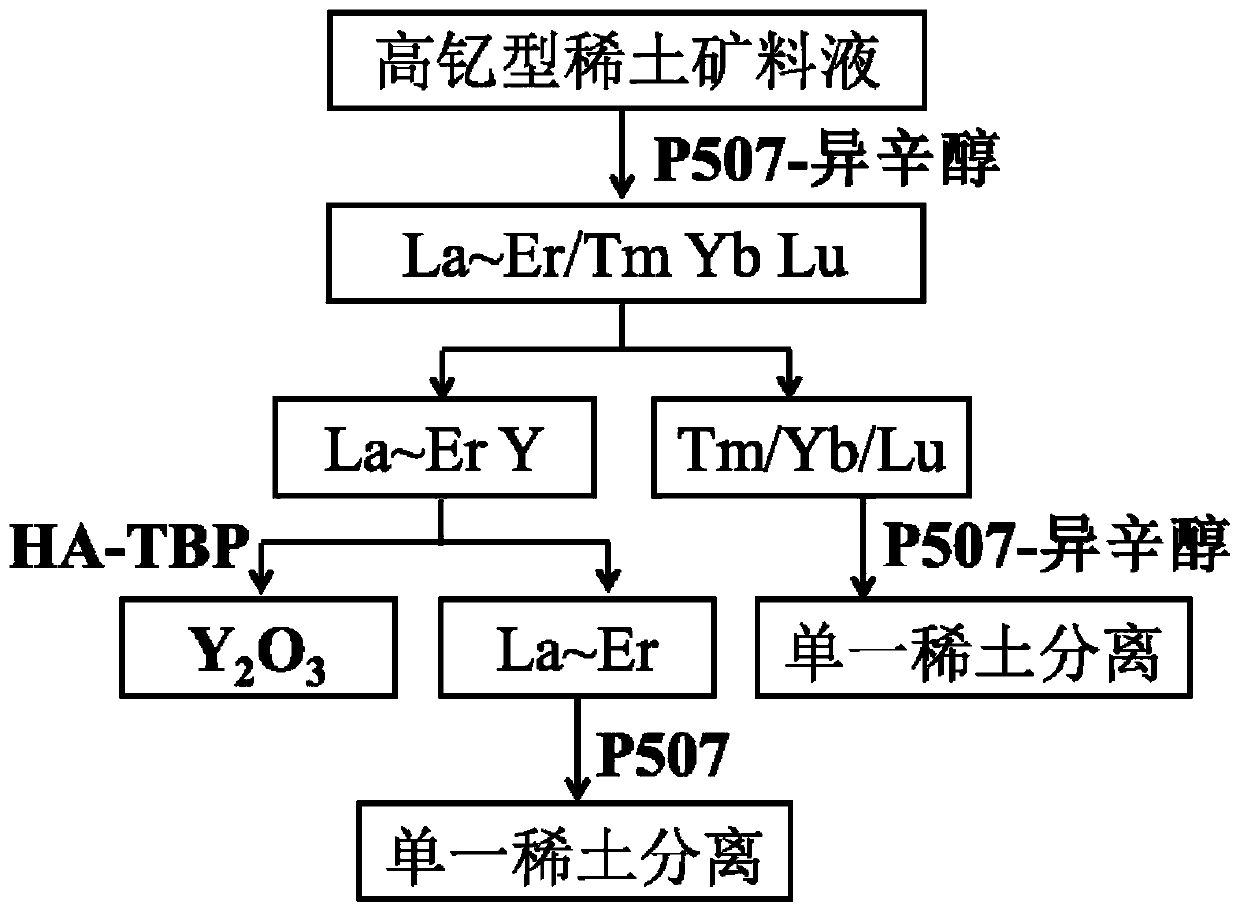

Method for grouping high-yttrium rare earth ore and separating yttrium oxide

A technology of rare earth ore and yttrium oxide, which is applied in the fields of rare earth metal compounds, chemical instruments and methods, and inorganic chemistry, and can solve problems such as separation difficulties, affecting process stability, and small separation coefficient of lanthanum and yttrium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1: The high-yttrium type rare earth ore liquid is grouped with erbium and thulium in a 1.0mol / L P507-20% isooctyl alcohol mixed system, and the degree of saponification is 36%. The organic phase is back-extracted with 5mol / L hydrochloric acid, and the raffinate aqueous phase is La ~Er Y component (yttrium-rich material), the organic phase is TmYb Lu component (thulium ytterbium lutetium enrichment). Thulium, ytterbium and lutetium concentrates are separated by a 1.0mol / L P507-20% isooctyl alcohol mixed system to separate a single heavy rare earth, and 5N lutetium oxide, 3N thulium oxide, and 5N ytterbium oxide can be obtained.

[0047] Step 2: The yttrium-rich feed solution is directly extracted and separated from yttrium oxide with a 0.50mol / L CA12-10%TBP mixed system, the degree of saponification is 80%, the organic phase is back-extracted with 3mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component. The organic phase is La-Er components, and...

Embodiment 2

[0050] Step 1: The high yttrium-type rare earth ore liquid is grouped with 0.5mol / L P507-0.5mol / L Cyanex272 mixed system erbium and thulium, the degree of saponification is 36%, the organic phase is back-extracted with 3.5mol / L hydrochloric acid, and the raffinate aqueous phase is La~Er Y component (yttrium-rich material), the organic phase is Tm Yb Lu component (thulium, ytterbium and lutetium enrichment). Thulium, ytterbium and lutetium concentrates are separated by a 0.5mol / L P507-0.5mol / L Cyanex272 mixed system to separate single heavy rare earths, and 4N lutetium oxide, 4N thulium oxide, and 4N ytterbium oxide can be obtained.

[0051] Step 2: Use 0.8mol / L CA12-20% TBP mixed system to directly extract and separate yttrium oxide from the yttrium-rich feed solution, the degree of saponification is 90%, the organic phase is back-extracted with 3.0mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component , the organic phase is La-Er components, and the raffi...

Embodiment 3

[0054] Step 1: The high-yttrium type rare earth ore liquid is grouped with 0.5mol / L P507-0.5mol / L P227 mixed system erbium and thulium, the degree of saponification is 36%, the organic phase is back-extracted with 3mol / L hydrochloric acid, and the raffinate aqueous phase is La ~Er Y component (yttrium-rich material), the organic phase is Tm Yb Lu component (thulium ytterbium lutetium enrichment). The thulium, ytterbium and lutetium concentrates are separated by a 0.5mol / L P507-0.5mol / L P227 mixed system to separate a single heavy rare earth, and 5N lutetium oxide, 4N thulium oxide, and 4N ytterbium oxide can be obtained.

[0055] Step 2: Use 0.8mol / L CA100-20% TBP mixed system to directly extract and separate yttrium oxide from the yttrium-rich feed solution, the degree of saponification is 90%, the organic phase is back-extracted with 3.0mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component , the organic phase is La-Er components, and the raffinate aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com