Coating machine based on switchover among three coating rolls

A technology of coating rollers and coating machines, which is applied to the device for coating liquid on the surface, coating, animal husbandry, etc. It can solve the problems that affect the drying quality of products, time-consuming and labor-intensive, and easy to shrink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Further description will be made below in conjunction with drawings and embodiments.

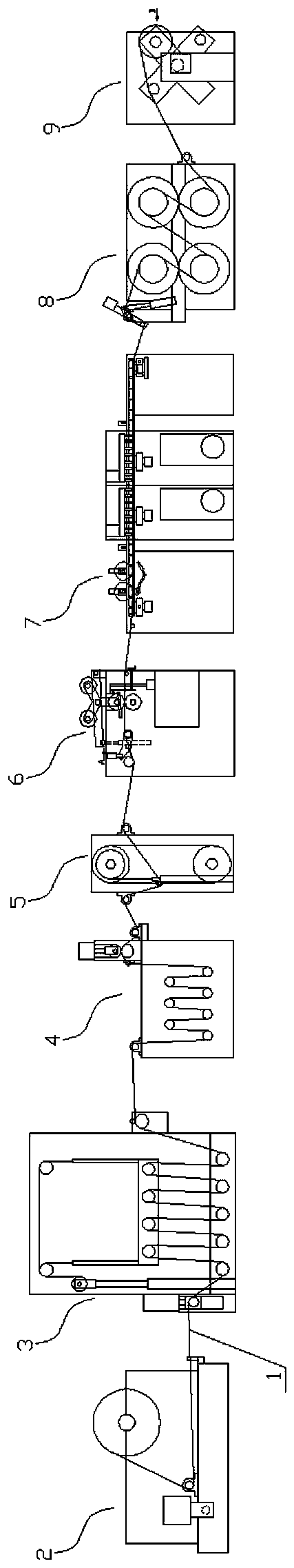

[0059] figure 1 Shown: an integrated production line of drying, coating and drying of luggage substrates includes an unwinding device 2, a storage and receiving device 3, a washing and dust removal device 4, a tension device 5, a three-coating roller switching coating machine 6, a puller The wide drying device 7, the water cooling device 8, and the winding device 9; the substrate 1 is sequentially connected to the above devices.

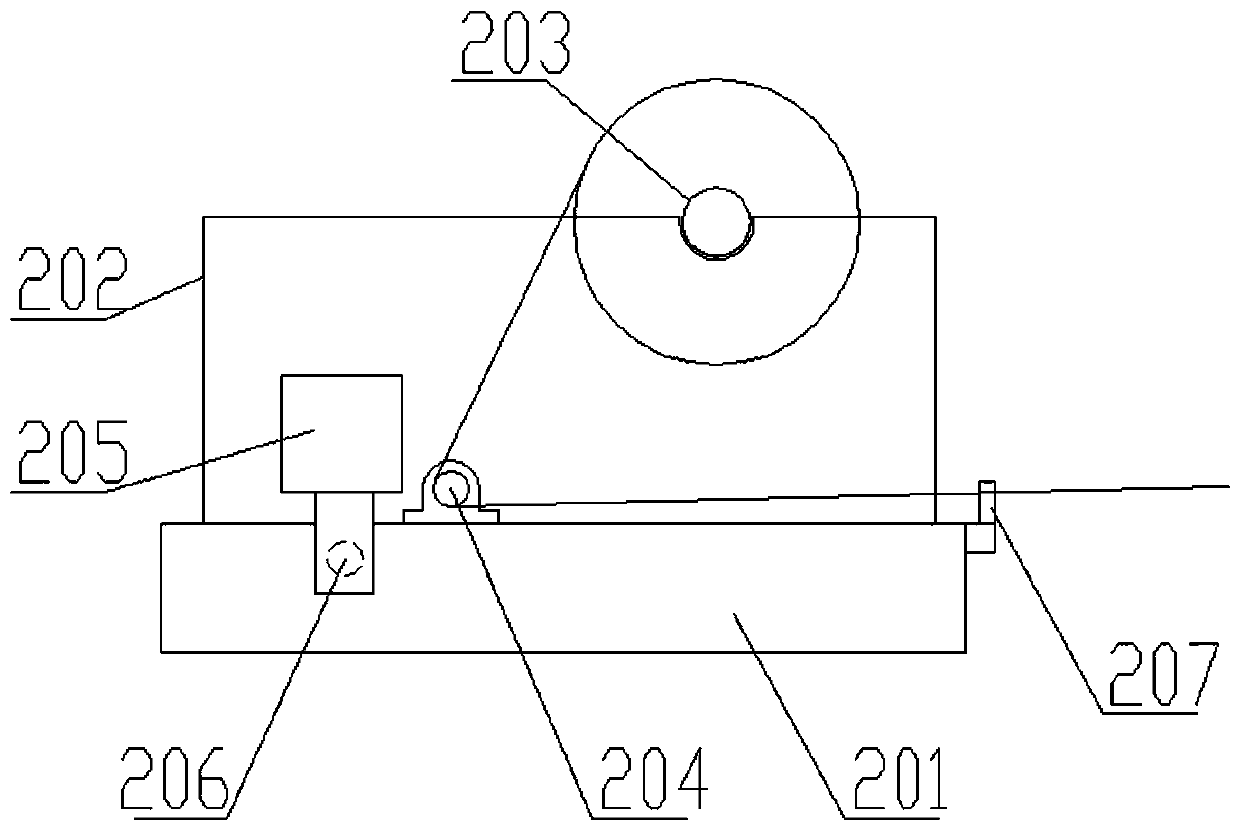

[0060] figure 2 The unwinding device 2 shown includes an unwinding base 201 , an unwinding support 202 , an unwinding shaft 203 , an unwinding reversing shaft 204 , a deviation correction motor 205 , a deviation correction screw 206 , and a deviation correction sensor 207 . The bottom of the unwinding support 202 is erected on the unwinding base 201 and is guided in the horizontal guide rail on the unwinding base through roller limit. The deviation-corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com