lidar

A lidar and radar technology, applied in the field of ranging, can solve the problems of increasing the difficulty of radar rotor design, occupying lidar space, and lack of tight shaft design, achieving good support, reducing cost and complexity, and improving measurement accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

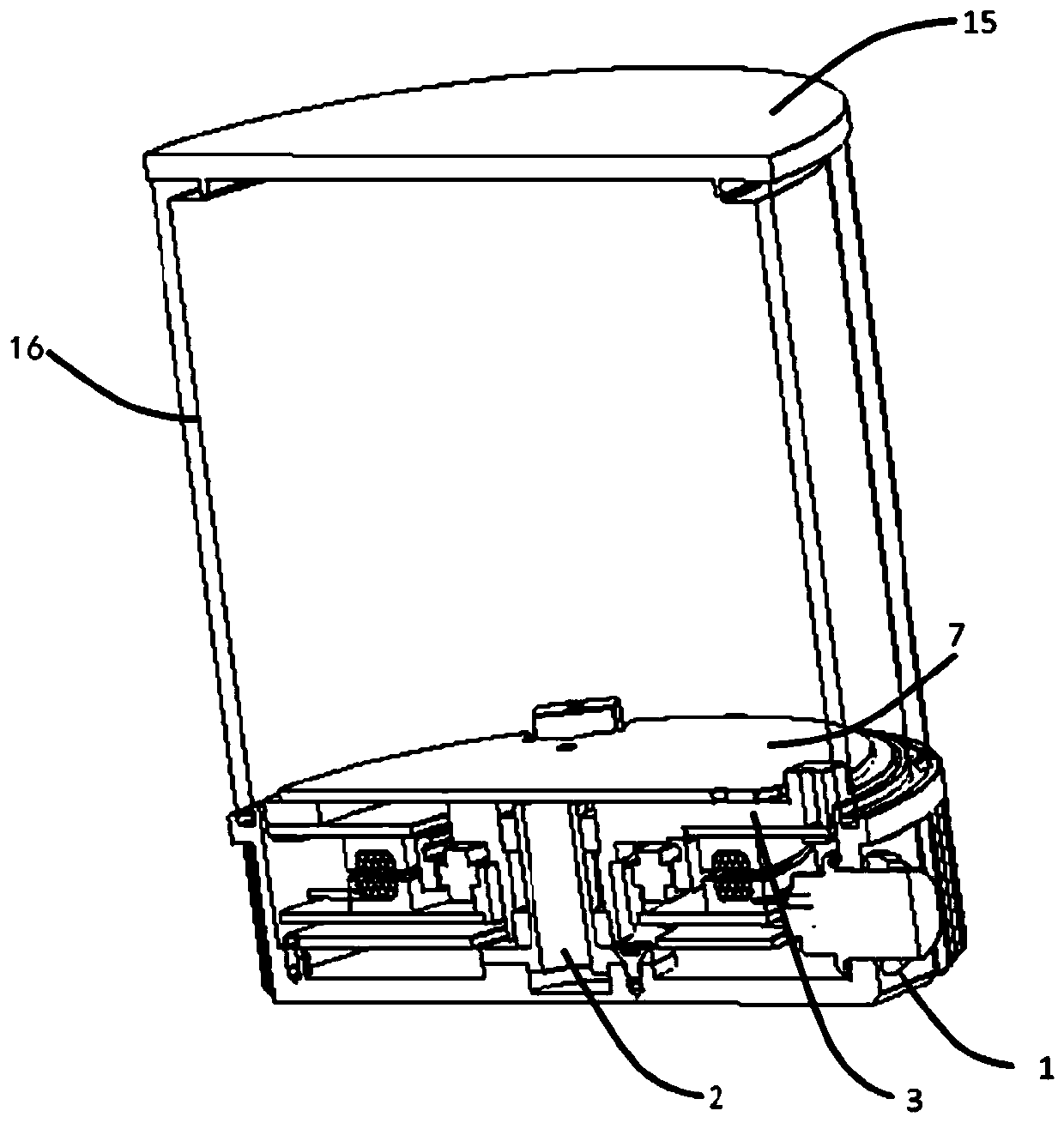

[0049] Embodiment 1: A laser radar, including a main shaft, a radar rotor, an upper bin plate, a top cover and a base;

[0050] The upper chamber plate is fixedly arranged with respect to the radar rotor, and the upper chamber plate is relatively closer to the base and farther away from the top cover in the axial direction of the lidar;

[0051] The main shaft is arranged perpendicular to the base and located between the upper bin plate and the base.

Embodiment 2

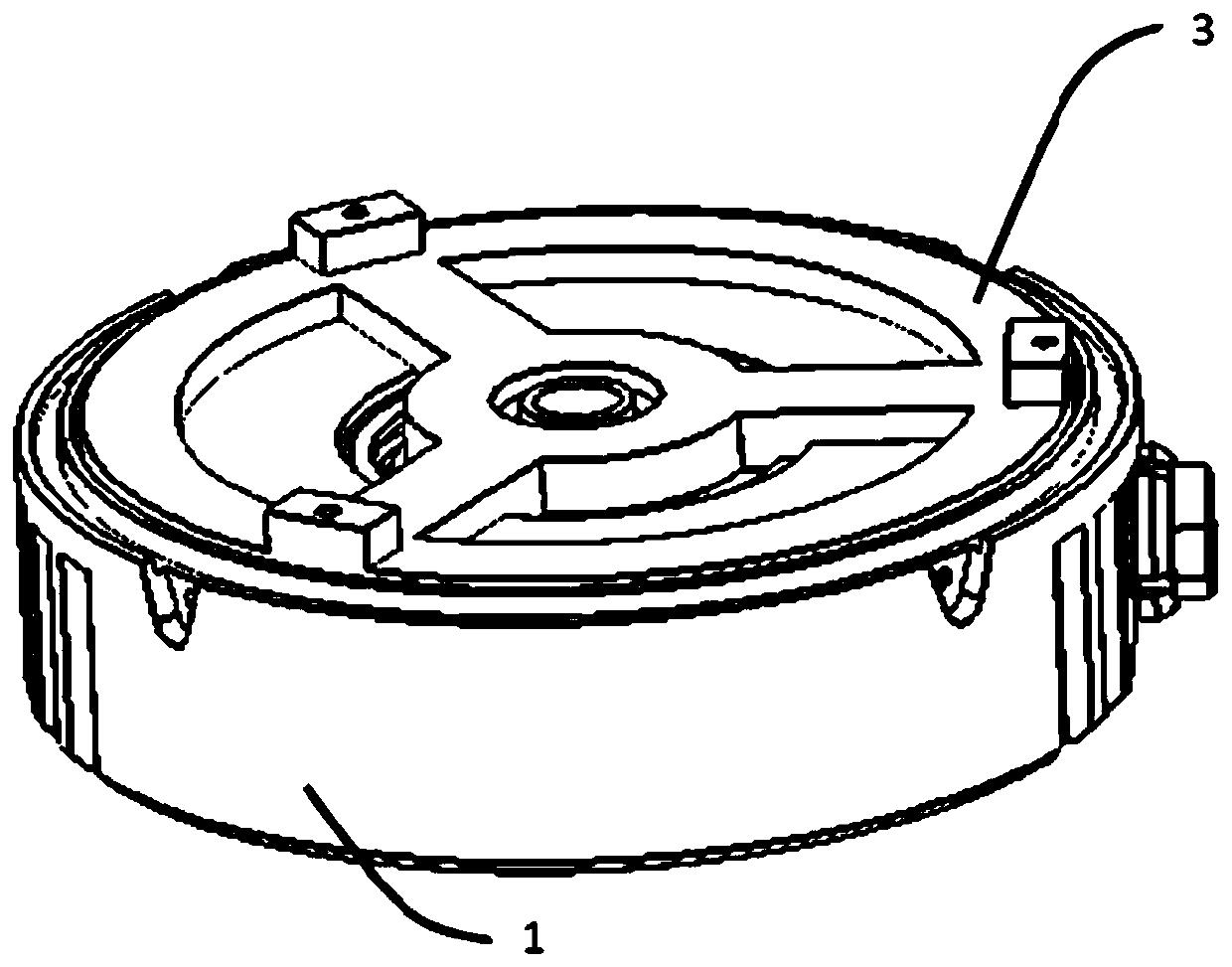

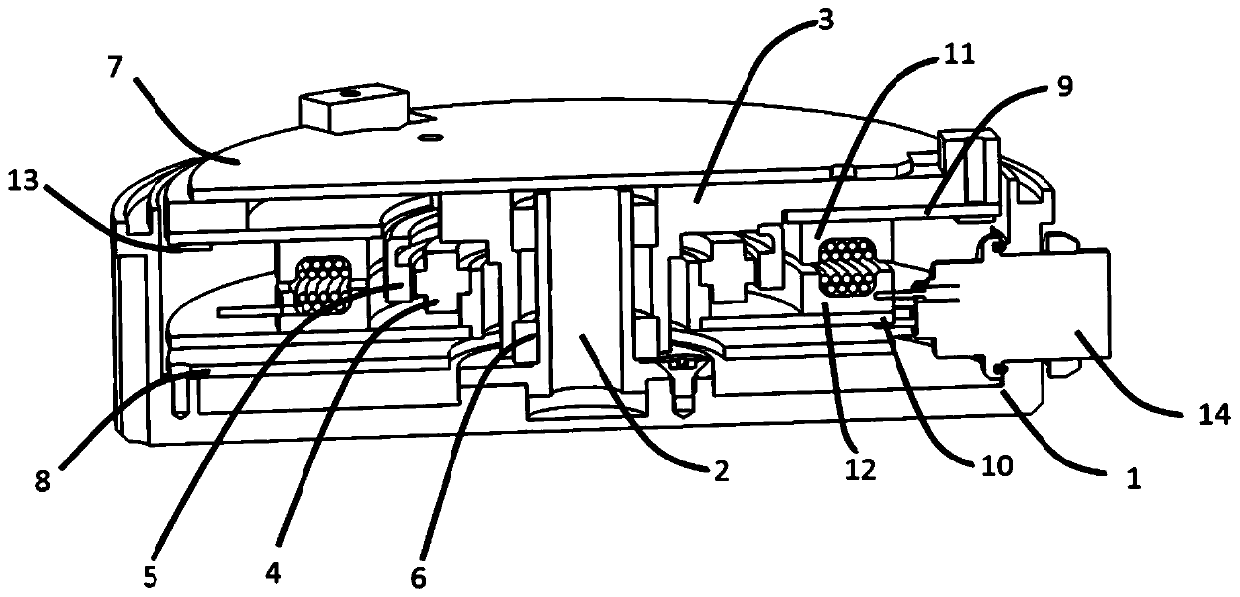

[0052] Embodiment 2: The lidar according to embodiment 1, further comprising a rotating support and a driving motor;

[0053] The rotating support includes a first part and a second part. The first part is a hollow structure and is suitable for sleeved on the main shaft, and the second part is a disk surface structure perpendicular to the first part and is suitable for Is coupled to the radar rotor, the second part includes at least three rotating sub-supports, the first end of each rotating sub-support is coupled to the first part, and the second part of each rotating sub-support The end is coupled to the edge of the disc surface of the second part, and the driving motor is adapted to drive the radar rotor to rotate through the rotating bracket.

Embodiment 3

[0054] Embodiment 3: According to the laser radar described in embodiment 2, a support flange is further provided at the coupling position between the second end of each of the rotating sub-supports and the edge of the disc surface. The protrusion direction is away from the base, and the radar rotor is adapted to be coupled with the rotating bracket through the supporting flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com