Determination method for stress between electrode particles during lithium ion battery discharge process based on electrochemical-mechanical coupling model

A lithium-ion battery and coupling model technology, applied in scientific instruments, material analysis by electromagnetic means, measurement devices, etc., can solve problems such as internal resistance increase, electrode material cracking, battery failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

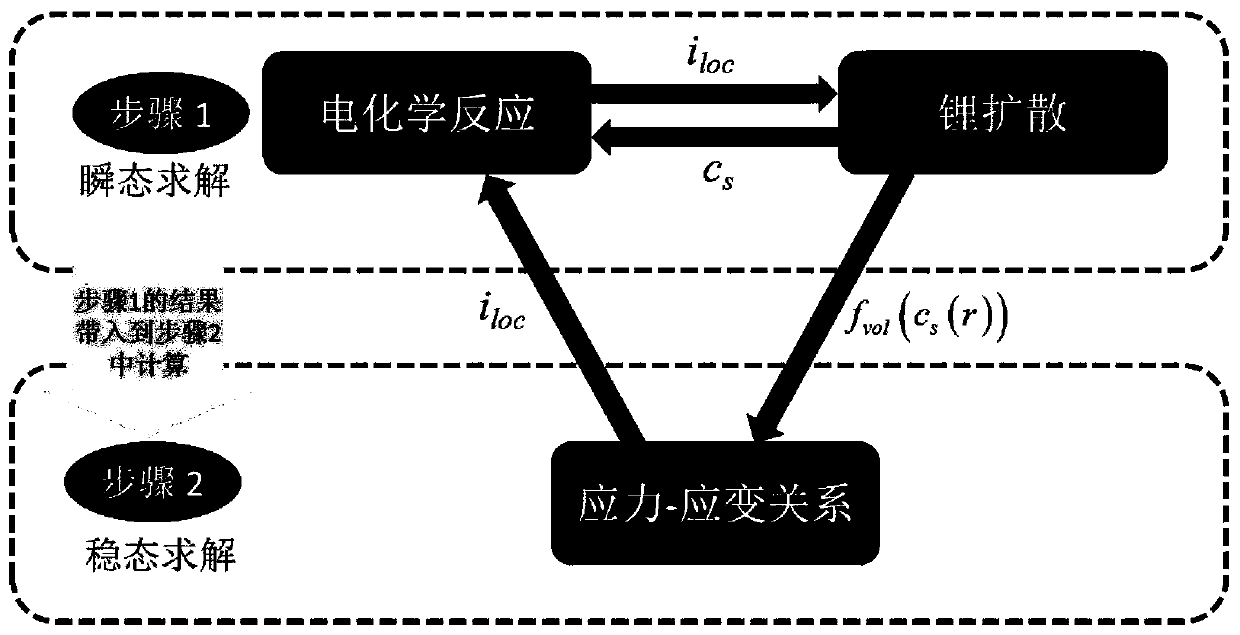

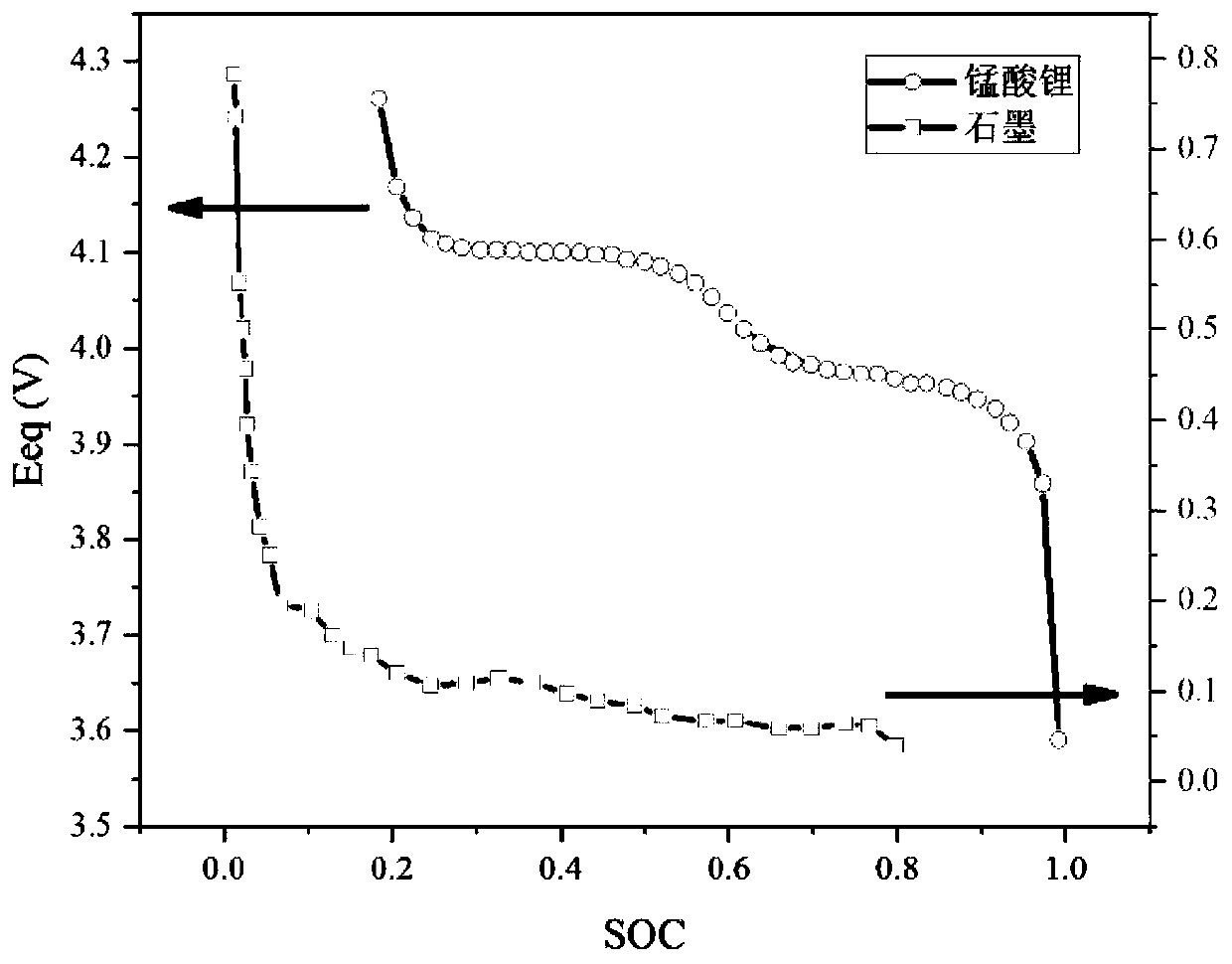

[0064] The cathode material is LiMn 2 o 4 (LMO), the negative electrode material is graphite as an example, the stress of the electrode particles of this lithium ion battery is calculated, and the present invention is described comprehensively and in detail. This method is not limited to the calculation of the stress between lithium manganate and graphite two kinds of material particles , which is applicable to all lithium-ion batteries composed of single electrode particles. The method is mainly divided into the following three parts: (1) the establishment of the model; (2) the calculation of the solid lithium concentration of the electrode particles; (3) the calculation of the stress between the negative electrode particles.

[0065] 1. First, describe the model building part, which is divided into 3 steps, as follows:

[0066] Step 1, parameter acquisition. The mechanical parameters of the electrode material and the electrochemical parameters of the battery are obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com