An installation structure of a concrete pumping mechanism hopper and a concrete pump truck

A concrete pump and installation structure technology, which is applied in the processing of building materials, building construction, construction, etc., can solve the problems of high production cost, material overflow, and difficult alignment of hopper mounting holes and rack mounting holes, etc., to achieve The effect of reducing the requirements of the production process and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

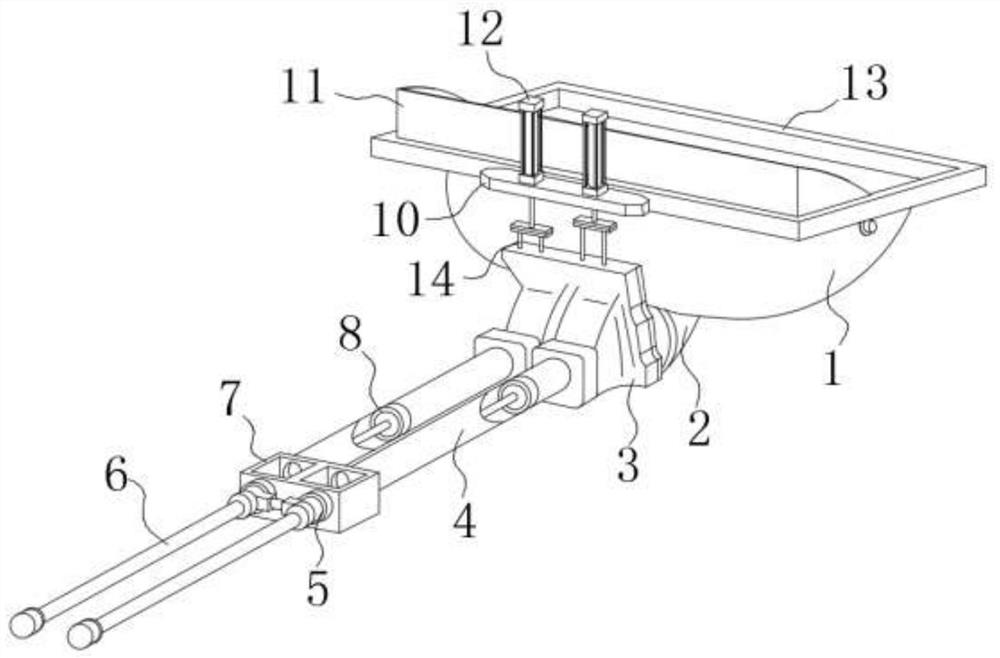

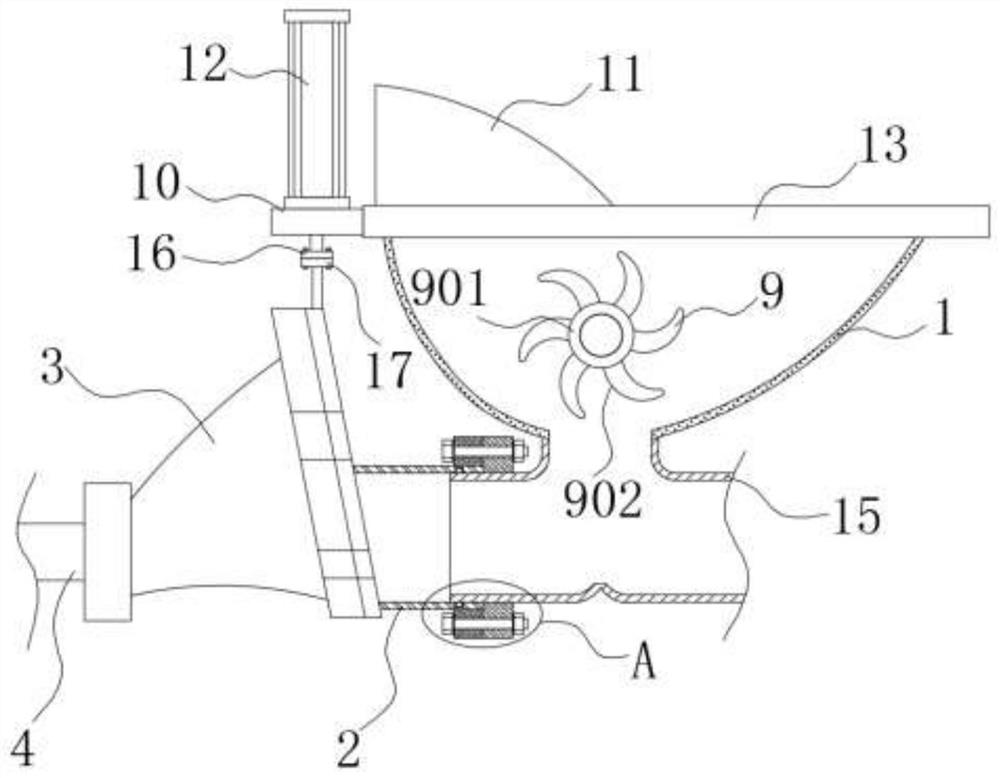

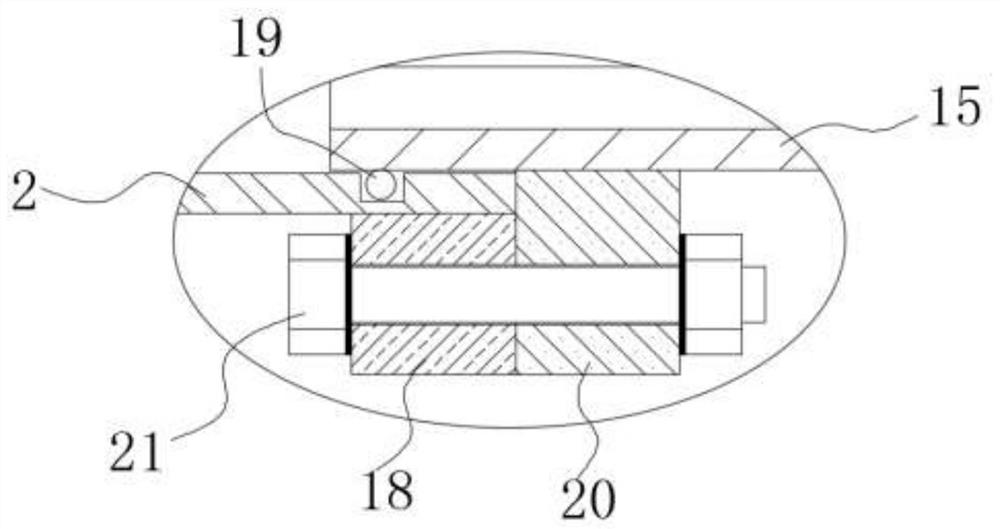

[0033] refer to Figure 1-6 , a concrete pumping mechanism hopper installation structure, including a hopper body 1, the lower end of the hopper body 1 is connected with a three-way pipe 15, and one end of the three-way pipe 15 is installed with a Y-shaped pipe 2, and the Y-shaped pipe 2 includes two receiving parts and a conveying part, and one end of the tee pipe 15 communicates with the conveying part, and the two receiving parts of the Y-shaped pipe 2 are jointly installed with a pumping frame for conveying concrete.

[0034] The pumping frame includes two slide valves 3, each receiving portion is equipped with a slide valve 3, and each slide valve 3 is symmetrically inserted with two telescopic rods 14, and the upper ends of the two telescopic rods 14 are jointly installed with The first connecting plate 17; the upper end surface of the hopper body 1 is equipped with an installation frame 13, the upper end surface of the installation frame 13 is equipped with a baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com