Novel forming and winding apparatus of glass fiber

A new type of glass fiber technology, applied in the field of new glass fiber forming and winding equipment, can solve the problems of not being able to meet the quality requirements of downstream customers, and achieve the effects of improving product quality, saving production costs, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

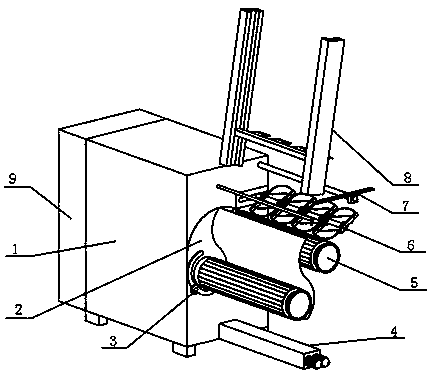

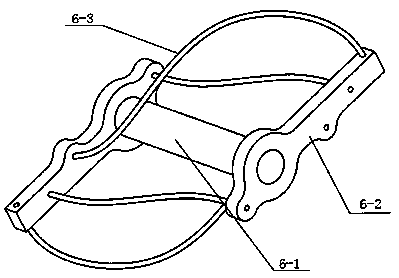

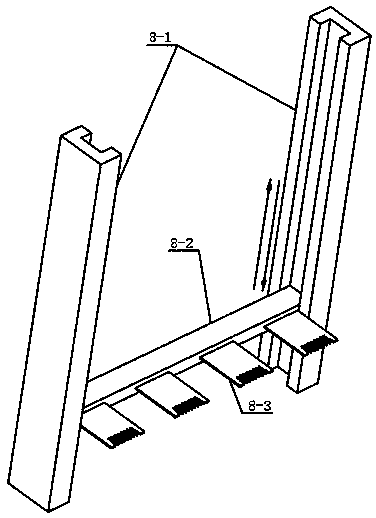

[0026] As shown in the figure, the present invention is a new type of glass fiber molding and winding equipment, including a main frame 1 and a main shaft installed on the main frame 1, a winding head 5, an arrangement mechanism 6, a can changing mechanism, and an automatic loading device 4 , automatic cylinder unloading device 3, forced beam splitter 8, water mist lubrication system, oil mist lubrication system, electrical control cabinet 9, drive motor, cylinder and lead screw, the cylinder changing mechanism includes rotating disk 2 and wire pushing device 7 ; The rotating disk 2 is installed on one side of the front middle of the main frame 1, the two main shafts are located in the main frame and symmetrically installed on the rotating disk 2, and the two winding heads 5 are located outside the main frame 1 and are connected to the main shaft Directly connected, the arrangement mechanism 6 is installed on the main frame parallel to the winding head 5 and above the winding h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com