Horizontal transportation type electrolytic plating apparatus enabling easy maintenance inspection

An electrolytic plating, horizontal technology, applied in the direction of current conduction device, contact device, electrolysis process, etc., can solve the problems such as difficult maintenance and inspection operations, internal maintenance and inspection operations of electroplating treatment tanks, clamping fixture obstacles, etc. , to achieve the effect of easy maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

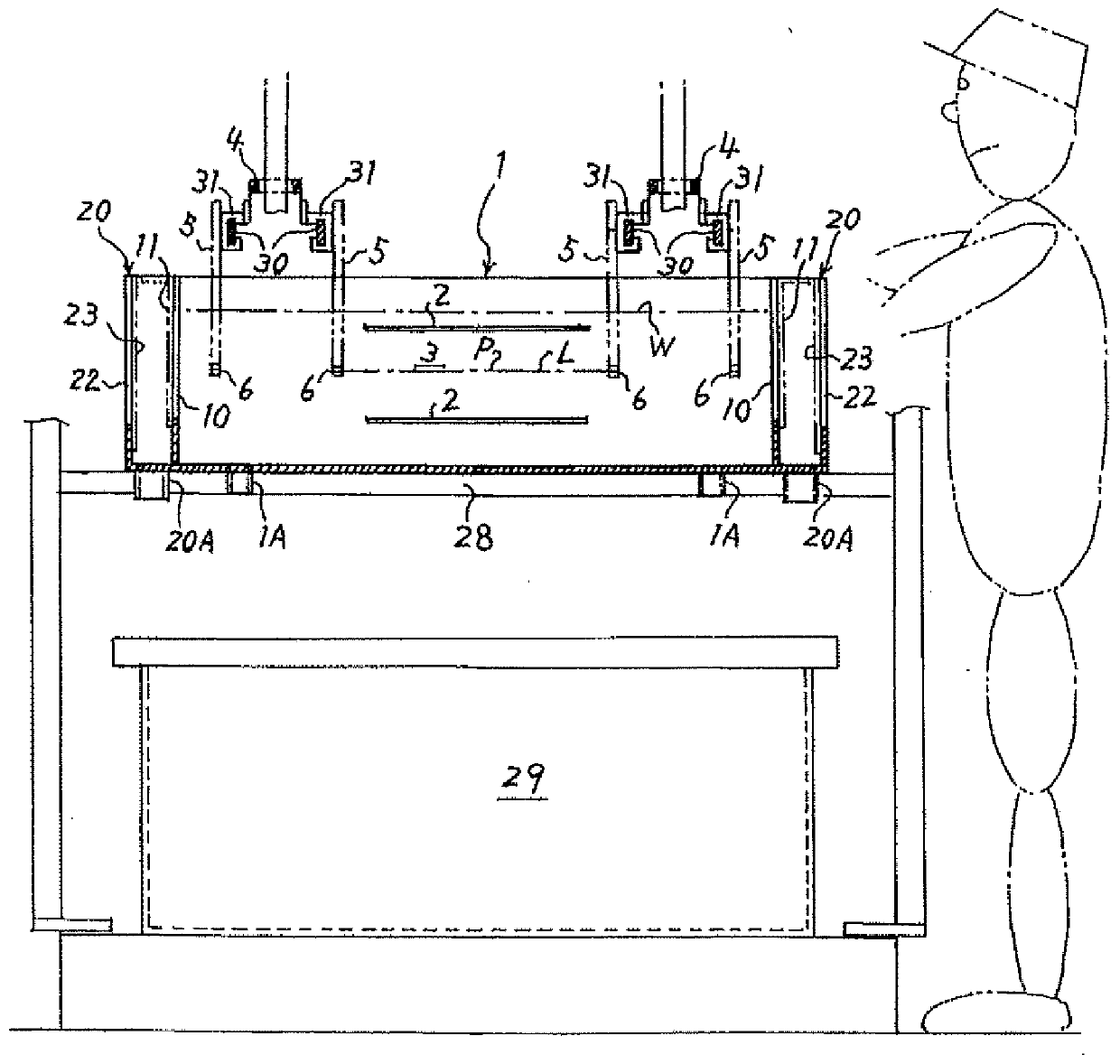

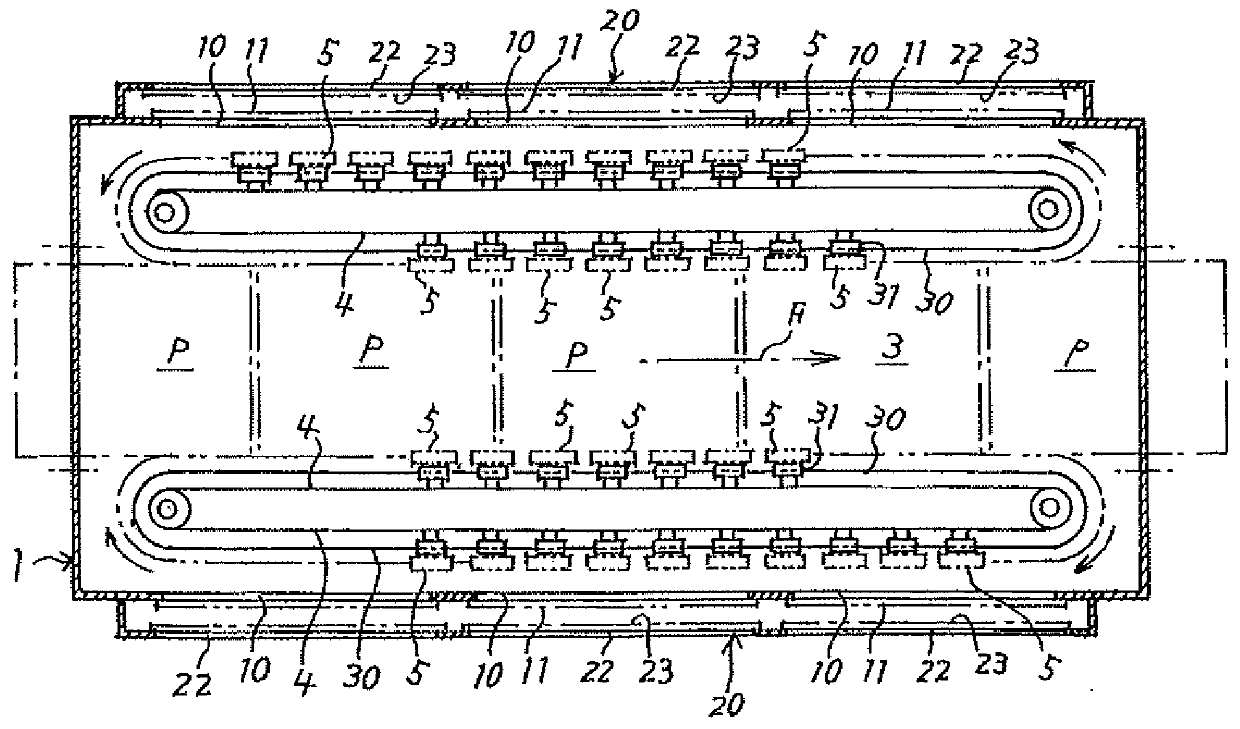

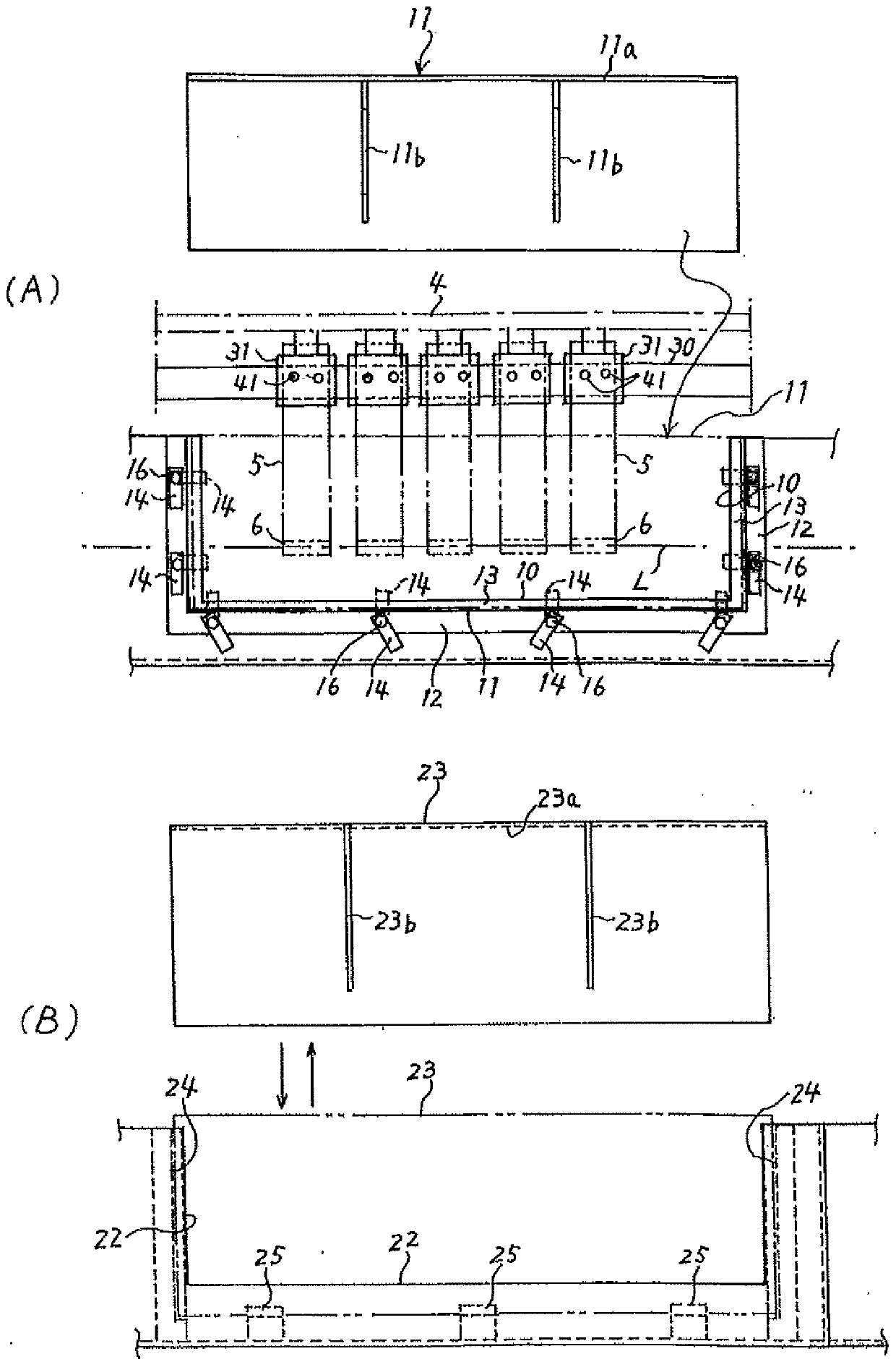

[0070] Embodiments of the present invention will be described based on the drawings. figure 1 and figure 2 It is a figure which schematically shows the whole of the horizontal conveyance type electrolytic plating apparatus of this invention. In this horizontal transport type electrolytic plating apparatus, rectangular substrate products P (thin plate-shaped products such as printed wiring boards) to which a cathodic current is supplied are supplied in a state where the board surfaces are up and down in the plating solution W in the electroplating treatment tank 1. Between the upper electrode and the lower electrode of the anode current (2, 2) in one direction ( figure 2 Arrow F direction) is conveyed horizontally, and the substrate product P is subjected to electrolytic plating treatment during the horizontal conveyance process. Also, in the illustrated embodiment, as a direction ( figure 2 The device for conveying the substrate product P horizontally in the arrow F dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com