A kind of dehydration and concentration method of industrial sludge

A technology for industrial sludge and sludge, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of long drying time of sludge cake, short service life of filter cloth, and processing cycle time. Long and other problems, to achieve the effect of prolonging the filter press time, shortening the working cycle and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

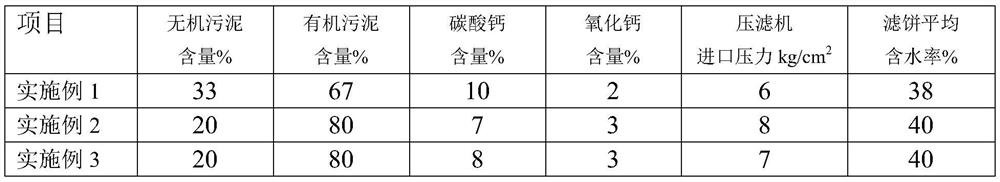

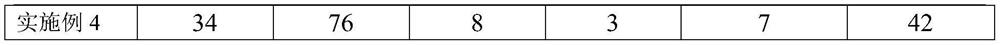

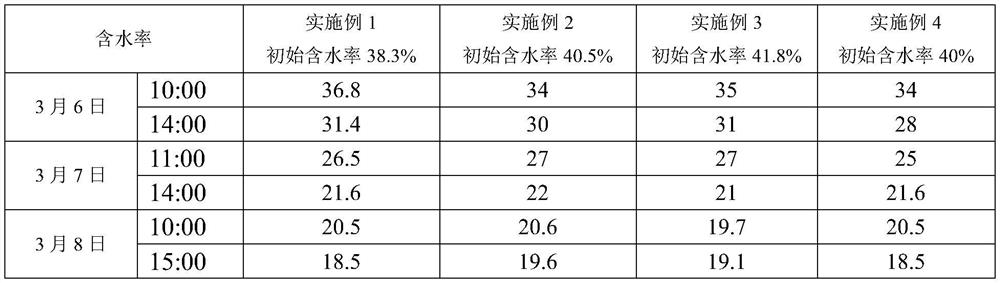

Embodiment 1

[0024] A dehydration of industrial sludge, including the following steps:

[0025] A, inject sludge and dehydration to 50M, respectively 3 In the first mixing tank of the volume, the addition of the dehydration agent is 100 L / 40m. 3 Sludge, pH 6, mixed temperature 25 ° C (can be used in winter, steam exposure can be heated), mixed time 25min;

[0026] B. After the first mixing tank is mixed by step A, the mixed product will be 0.45m. 3 / min flow rate self flows 30M 3 Volume second mixing can, add lime, lime added to 8kg / m 3 Sludge, control pH 8, a mixed time of 12 min, the mixing temperature is room temperature, the bottom of the can body in the second mixing can body communicates with a aeration pipe;

[0027] C. After the second mixing tank of step B is processed, the mixed product is 0.45m. 3 / min flow rate self flows 10M 3 The volume of the third mixing tank, anionic polyacrylamide having a mass concentration of 1 ‰, 1 ‰ of the sludge flowing out with respect to the thir...

Embodiment 2

[0030] A dehydration of industrial sludge, including the following steps:

[0031] A, inject sludge and dehydration to 50M, respectively 3 In the first mixing tank of the volume, the addition of the dehydration agent is 100 L / 40m. 3 Sludge, pH 6, mixed temperature 25 ° C, mixed time 20 min;

[0032] B, after mixing by the first mixing tank step A, the mixed product will be 0.35m. 3 / min flow rate self flows 30M 3 The volume of the second mixing can, replace the waste residue for the disulfurization of the power plant, the water content of the waste residue is 50%, and the addition is 20 kg / m. 3 Sludge, (the addition of waste residue ensures that the addition of lime reaches 9kg / m 3 Sludge, waste saga is adjusted in the total amount of calcium oxide and calcium carbonate, the content is high, the amount is less; the content is low, the amount of addition is more, which depends on the utilization rate of lime in desulfurization). The control pH 8.5 is controlled, the mixed ti...

Embodiment 3

[0036] A dehydration of industrial sludge, including the following steps:

[0037] A, inject sludge and dehydration to 50M, respectively 3 In the first mixing tank of the volume, the addition of the dehydration agent is 100 L / 40m. 3 Sludge, pH 5.5, mixed temperature 23 ° C, mixed time 23min;

[0038] B, after mixing by the first mixing tank step A, the mixed product is 0.4m. 3 / min flow rate self flows 30M 3 The volume of the second mixing tank, add lime, lime added is 10kg / m 3 Sludge, control pH 8.6, a mixed time of 15 min, and the mixing temperature is room temperature, and the bottom of the tank of the second mixing tank is connected to a aeration pipe;

[0039] C, after the second mixing tank of step B, the mixed product will be 0.4m. 3 / min flow rate self flows into 13M 3 The volume of the third mixing tank, adding a polyacrylamide having a mass concentration of 1 ‰, an amount of 1 ‰, the mixture is 28s, the mixing temperature is room temperature, the tank bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com