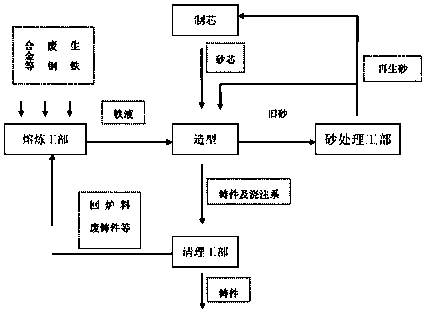

Casting process flow

A technology of process flow and process, applied in foundry workshops, manufacturing tools, casting equipment, etc., can solve the problems of low sand casting production efficiency, cost increase, material waste, etc., achieve high production efficiency, save casting materials, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0012] like figure 1 As shown, a casting process includes smelting, sand treatment, core making, molding and cleaning processes; specifically, firstly, the molding sand obtained from sand treatment is used for core making, and the process is used to obtain sand cores and molds; secondly, the molten iron obtained from smelting, The sand cores and molds obtained from core making are molded to obtain casting products; the third is cleaning. The molding sand used in the casting process is renewable sand. After molding, the used sand that has been used is returned to the sand treatment process for processing; The scrap iron and scrap castings are returned to the smelting process for smelting and reuse. The raw materials used in the smelting process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com