Demolding mechanism of automobile hub mold

A technology of automobile wheel hub and demoulding mechanism, which is applied in the field of demoulding mechanism, and can solve problems such as damage to the demoulding mechanism and wheel hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

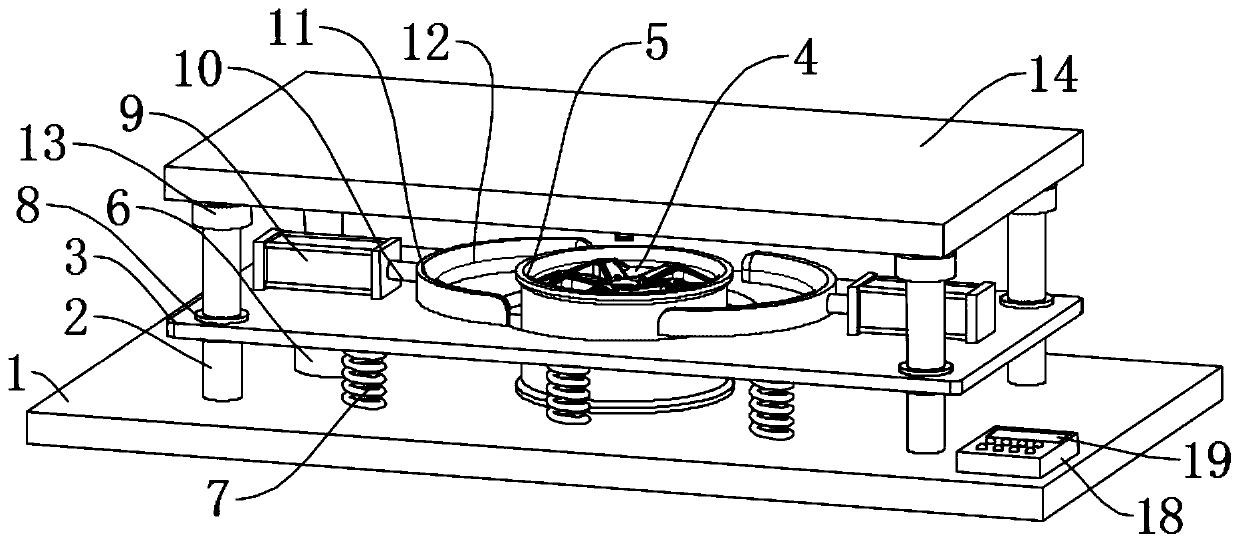

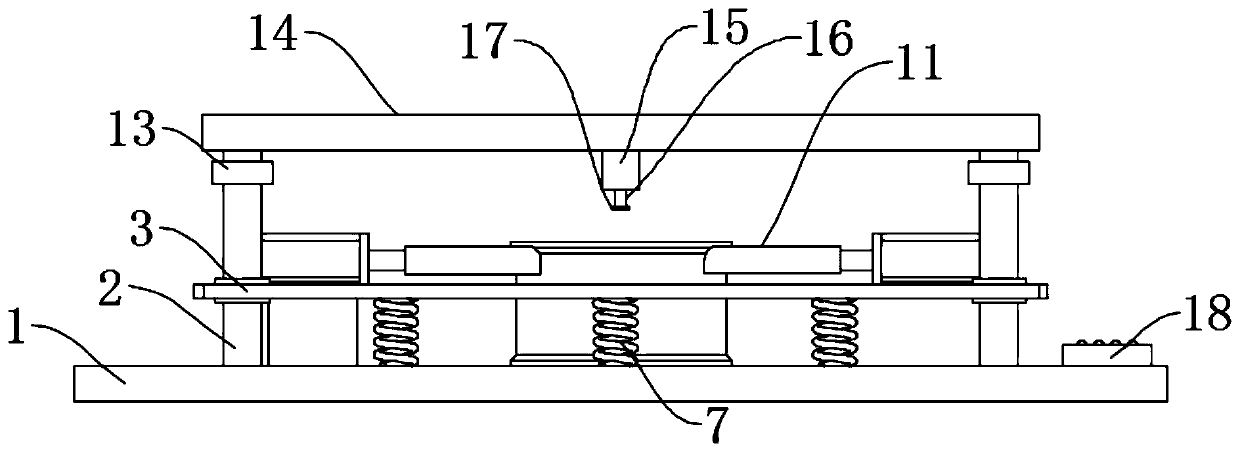

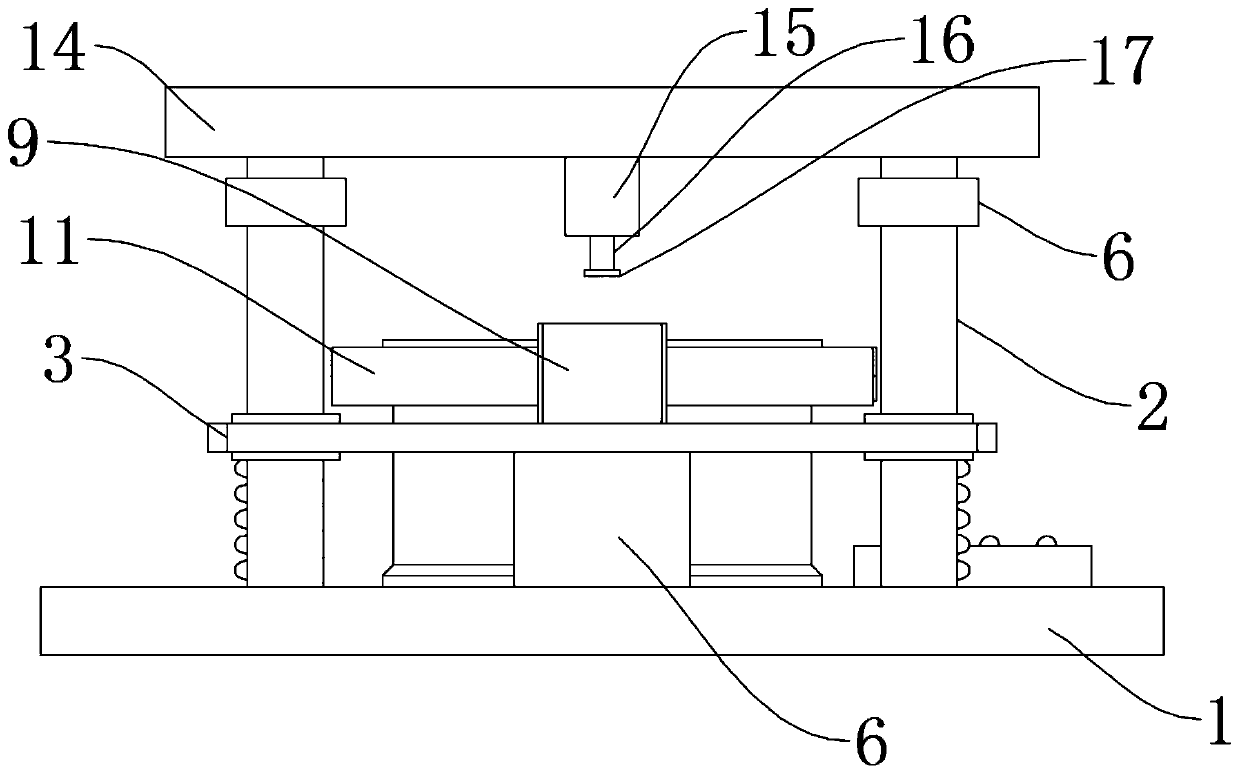

[0028] Such as Figure 1-Figure 5 As shown, a demoulding mechanism for an automobile wheel hub mold includes a bottom plate 1, a lifting plate 3, a mounting plate 14, and a control panel 18. The upper end of the bottom plate 1 is provided with a limit post 2, and the limit post 2 is used to make the lift plate 3 rise steadily. , the limit column 2 and the bottom plate 1 are connected by bolts, a sliding sleeve 8 is arranged on the outside of the limit column 2, a lifting plate 3 is arranged on the outside of the sliding sleeve 8, a through hole 21 is arranged in the lifting plate 3, and a through hole 21 is arranged in the There is a mold 4. The function of the mold 4 is to cooperate with the upper mold to die-cast the wheel hub 5. The wheel hub 5 is arranged on the outside of the mold 4, and the hydraulic cylinder 6 is arranged on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com