Inner hole shaping machine

A technology of shaping machine and inner hole, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of easy change of inner hole size and roundness, unfavorable use, inner hole shaping without multiple pipe fittings, etc. To achieve the effect of improving processing adaptability, improving work efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

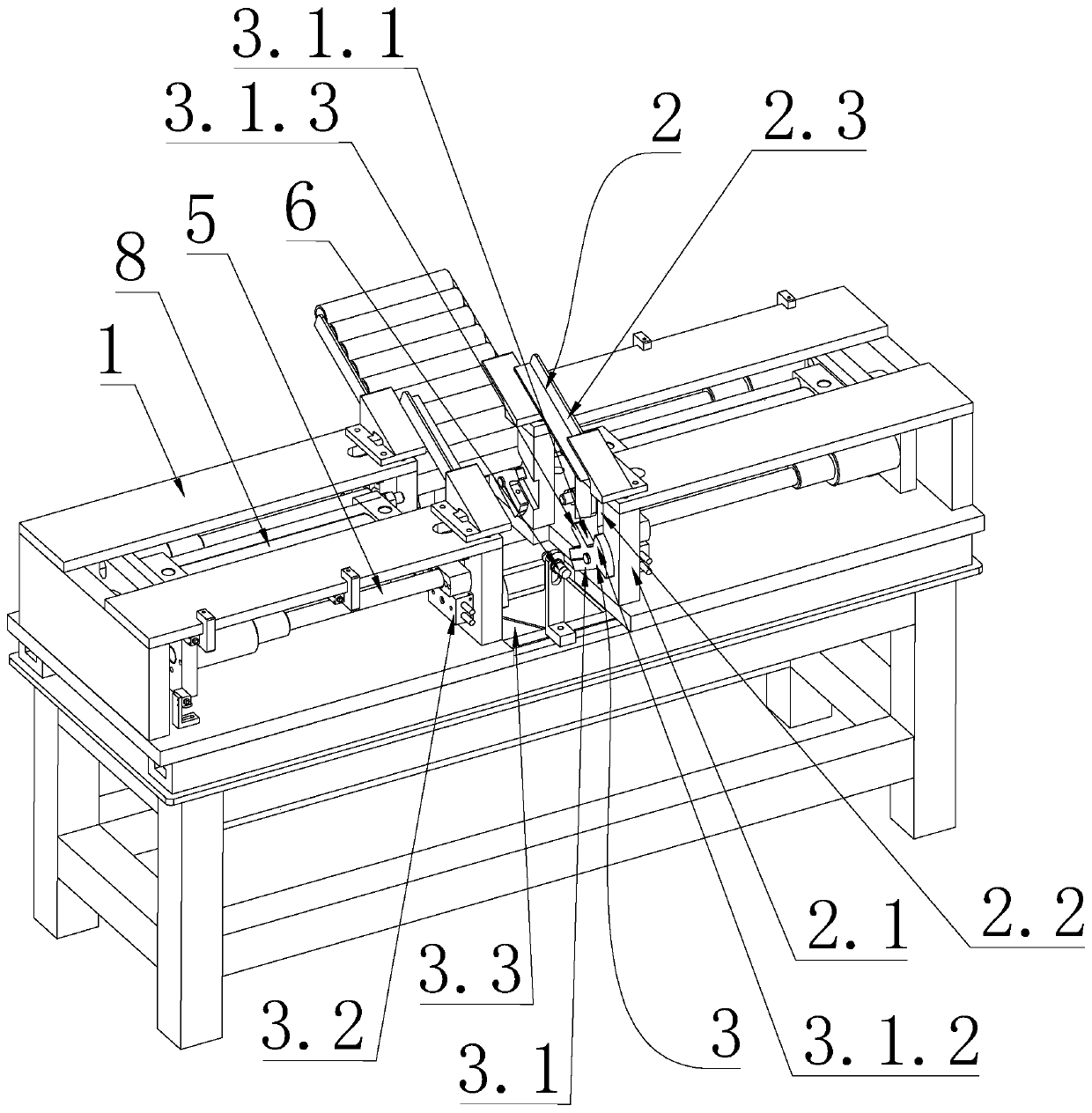

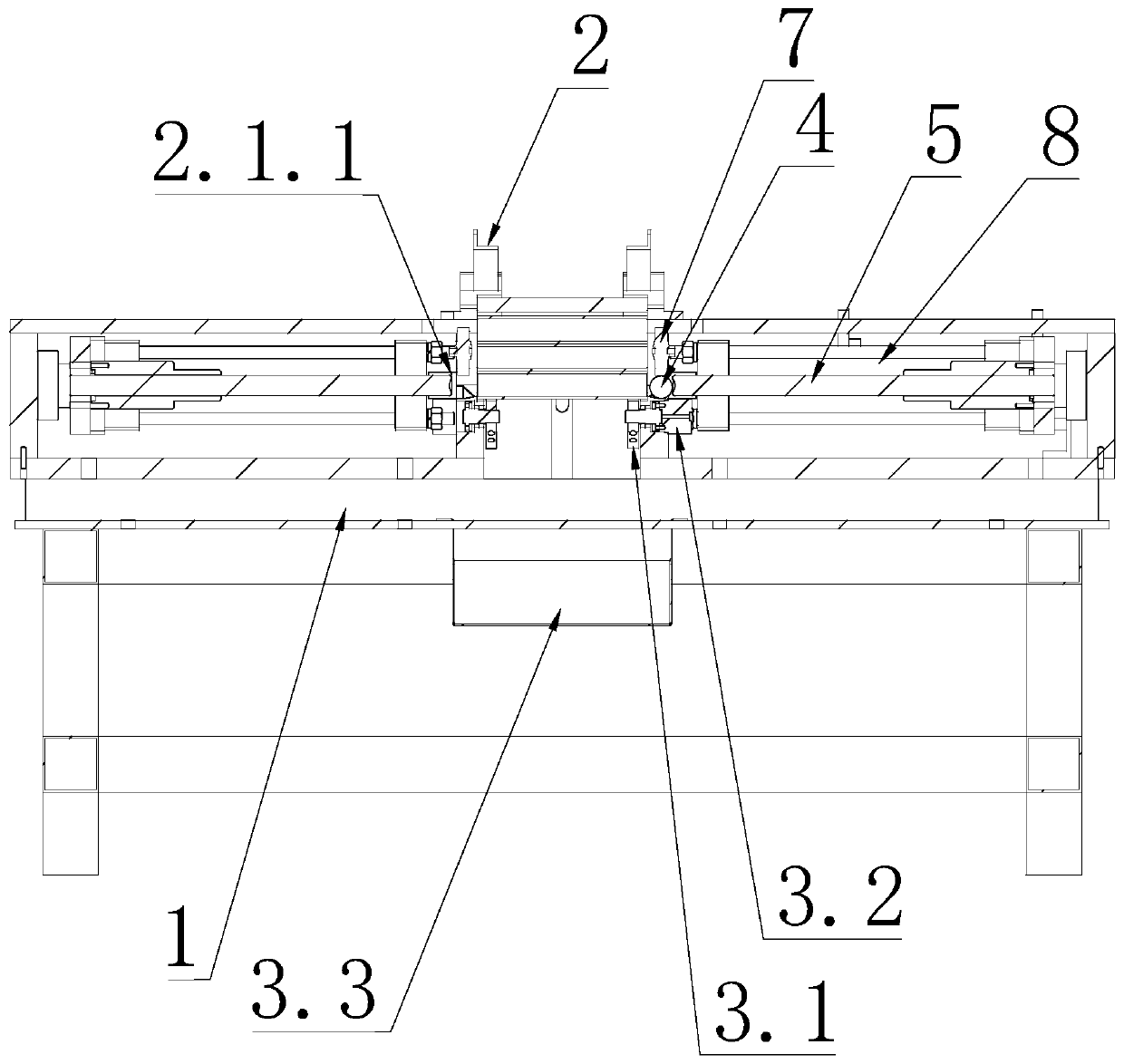

[0039] Such as Figure 1~2 shown

[0040] A kind of inner hole shaping machine, it comprises frame 1, at least one set of inner hole shaping mechanism arranged on frame 1, each group of said inner hole shaping mechanism includes:

[0041] Shaping station, set in the middle of frame 1;

[0042] The feeding assembly 2 is used to continuously transport the pipe fittings to be shaped to the shaping station;

[0043] The blanking assembly 3 is arranged at the lower part of the shaping station for outputting the shaped pipe fittings;

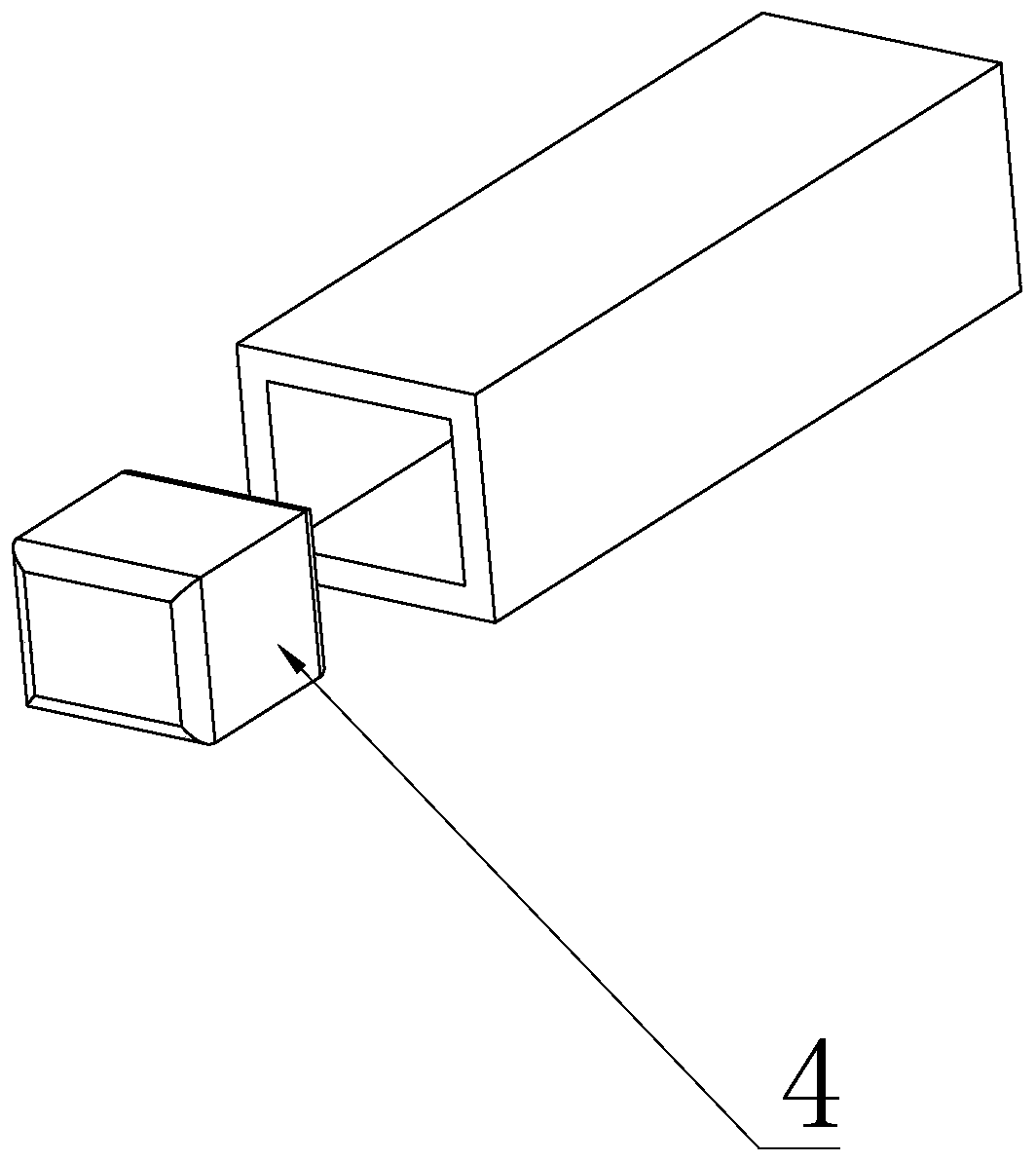

[0044] Shaping part 4, the size of the shaping part 4 is consistent with the size of the pipe fitting inner hole to be shaped;

[0045] Push rod 5, the number of the push rod 5 is two and is respectively arranged on both sides of the shaping station, the push rod 5 is used to push the shaping part 4 through the inner hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com