Electric automatic equipment maintenance protection device and use method thereof

A technology of electrical automation and equipment maintenance, applied in life-saving equipment, building rescue, etc., can solve the problems of safety rope maintenance personnel falling, etc., to avoid potential safety hazards, improve life safety, and ensure the effect of safe landing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

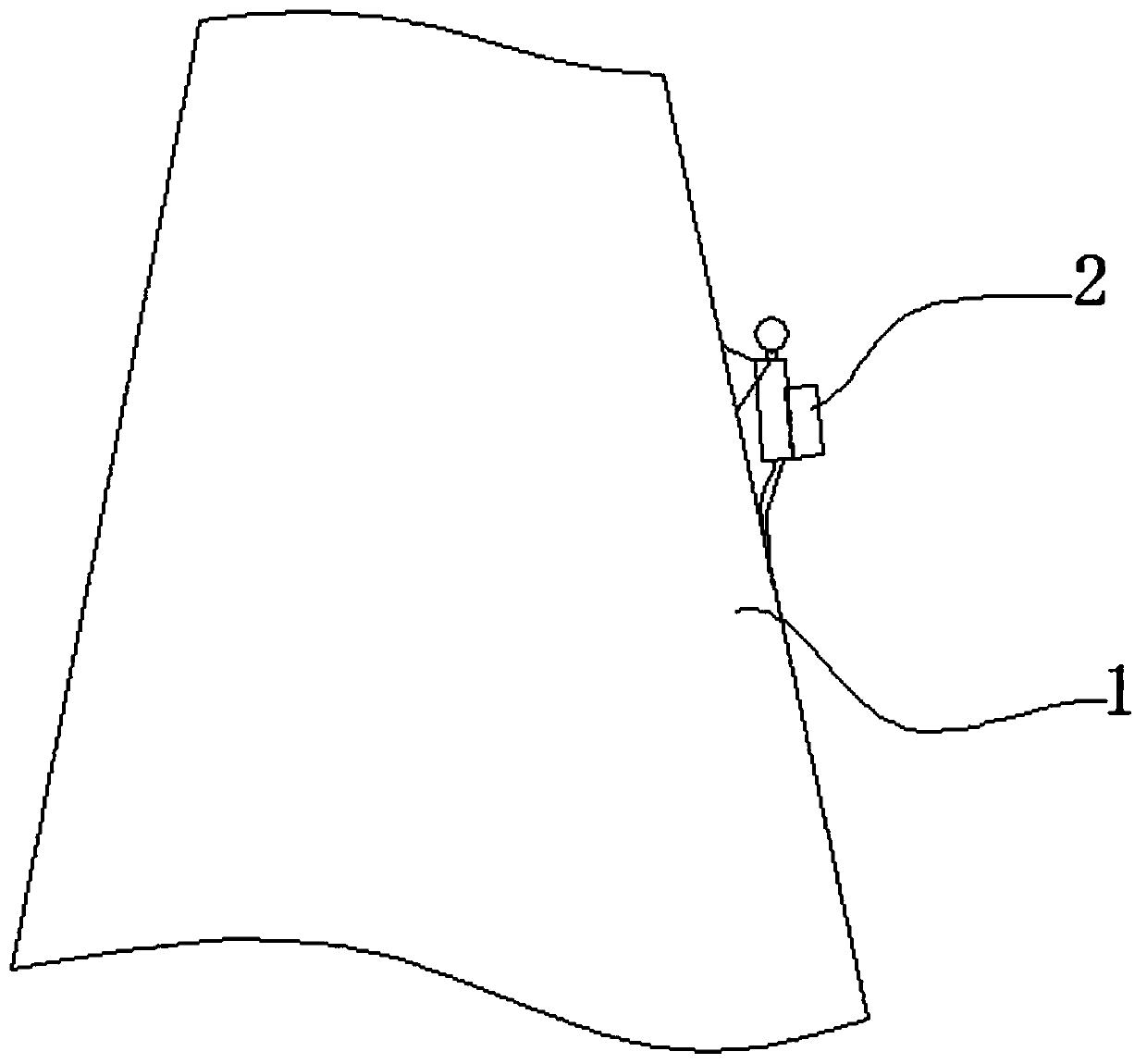

[0036] like figure 1 As shown in the figure, an overhaul protection device for electrical automation equipment includes a parachute 2 for maintenance personnel to carry on their backs and a control device 3 for controlling the opening of the parachute 2; the maintenance personnel carry the parachute 2 on their backs for operation; Used to control parachute 2 to open. The electrical automation equipment maintenance protection device disclosed in the present embodiment can control the opening of the parachute 2 through the control device 3, so as to ensure the safe landing of the maintenance personnel, avoid potential safety hazards when the maintenance personnel fall, and ensure the life safety of the maintenance personnel.

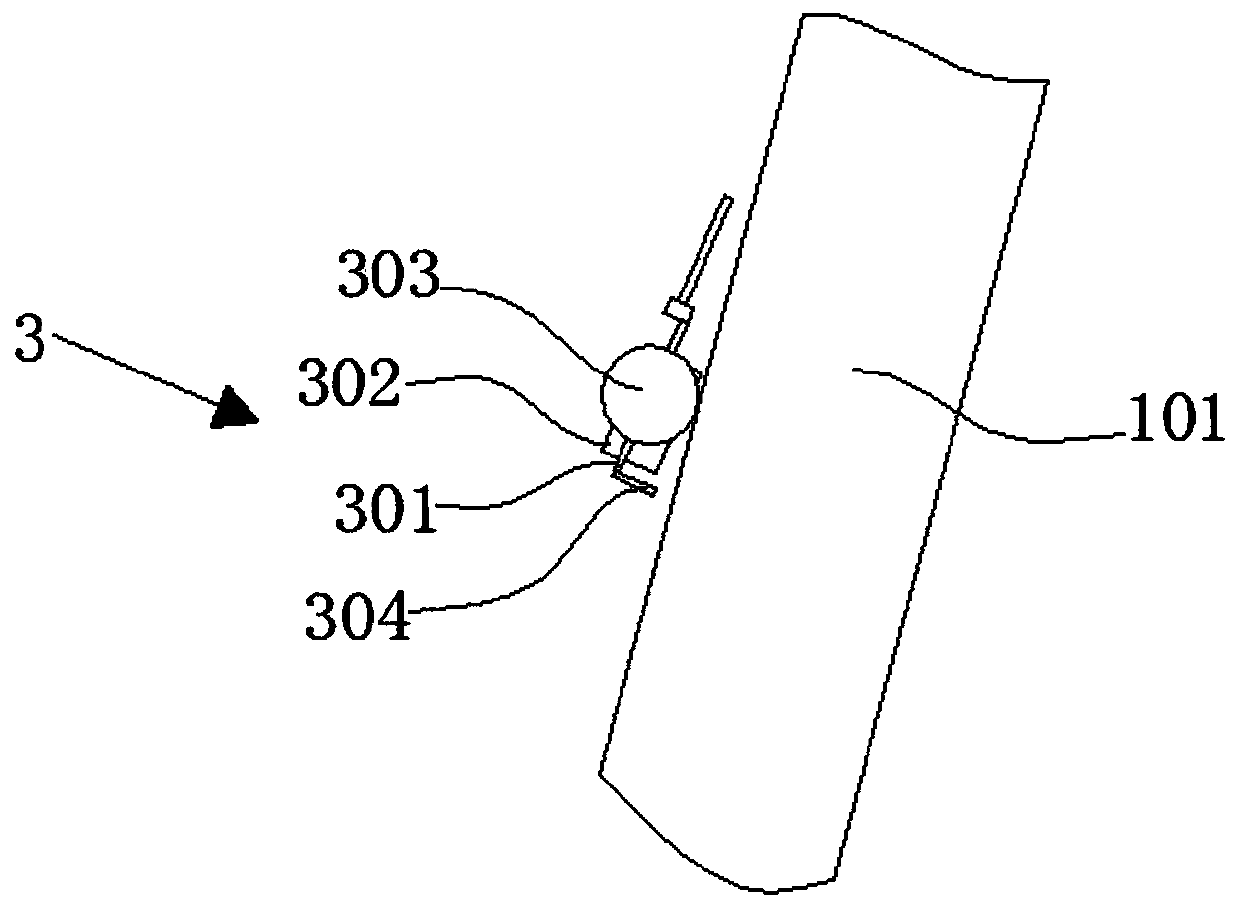

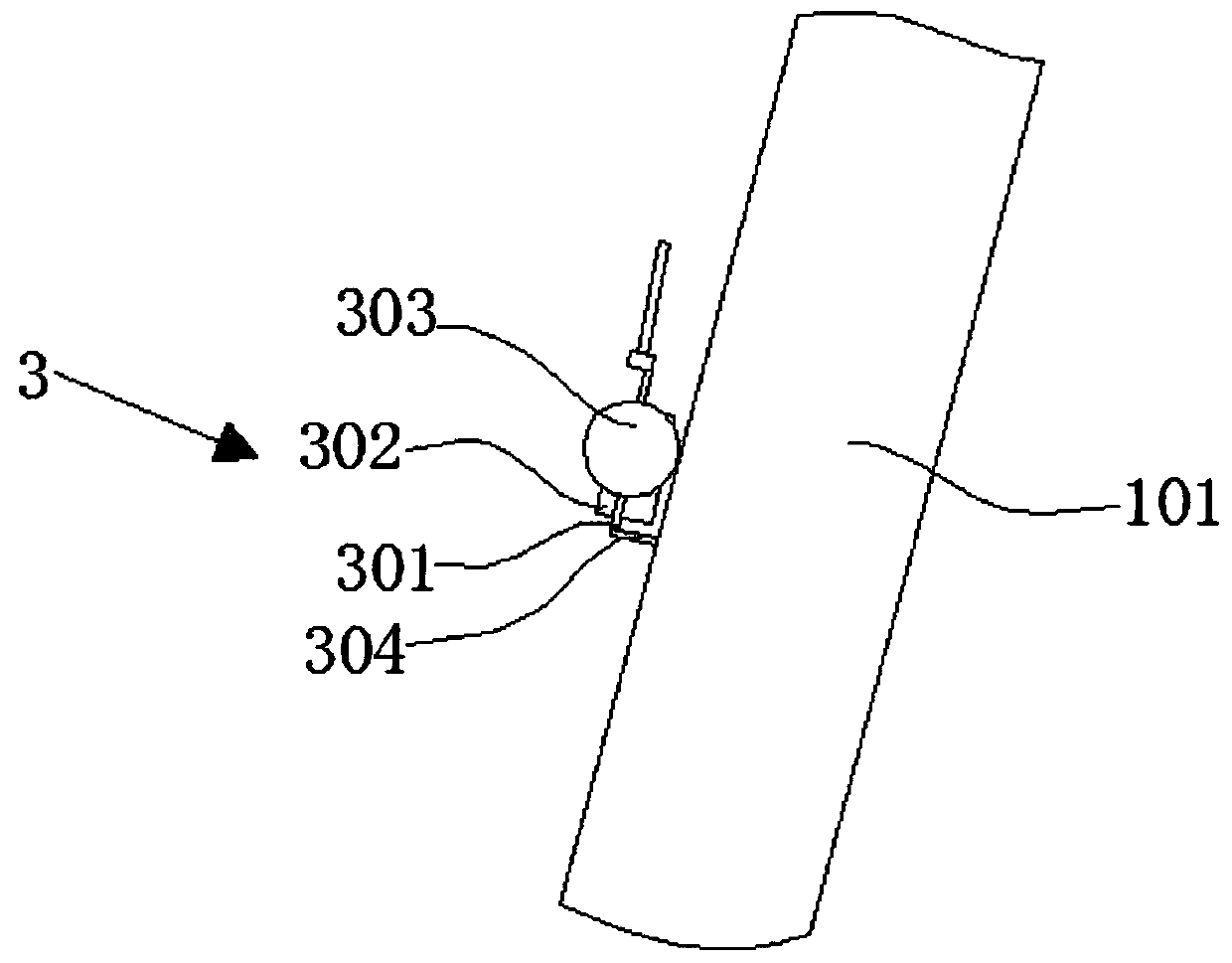

[0037] like figure 2 and image 3 As shown, the iron tower 1 includes a support rod 101, and maintenance personnel climb the support rod 101 to perform operations to a desired height; the control device 3 includes a support frame 301 and a magnet 302; t...

Embodiment 2

[0040] With the embodiment 1, the difference is: as Figure 4 As shown, the control device 3 includes a casing 305 and a rotating shaft 306; the casing 305 is connected with the iron tower 1 through a first safety rope; the rotating shaft 306 is rotatably connected in the casing 305, and the rotating shaft 306 is wound with a The second safety rope; one end of the second safety rope is connected to the pull ring of the parachute 2 after passing through the casing 305 .

[0041]In the electrical automation equipment maintenance protection device disclosed in this implementation, when the maintenance personnel accidentally drop, the control device 3 used in the control device 3 drives the rotating shaft 306 to rotate through the second safety rope. The rotating speed of the parachute 2 is constant, the rotating shaft 306 gives a pulling force to the pull ring on the parachute 2 through the second safety rope, and then pulls the pull ring on the parachute 2, the parachute 2 opens...

Embodiment 3

[0043] The same as Embodiment 1, the difference is: the control device 3 includes an acceleration sensor and a trigger device; the acceleration sensor is installed on the maintenance personnel; the trigger device is used to give the pull ring pulling force of the parachute 2; The acceleration sensor described above detects an acceleration greater than 8m / s 2 When the trigger device moves, the pull ring of the parachute 2 is pulled.

[0044] As a further improvement, the acceleration sensor detects an acceleration of 9.8m / s 2 When the trigger device moves, the pull ring of the parachute 2 is pulled.

[0045] In the electrical automation equipment maintenance protection device disclosed in this embodiment, when the maintenance personnel accidentally drop, the acceleration sensor transmits an action signal to the triggering device, and the triggering device acts to pull the pull ring of the parachute 2 to open the parachute, ensuring that the maintenance personnel safely land. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com