Cabin cover rigidity and stability determination method

A determination method and nacelle cover technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as inaccurate calculations and few applications, and achieve accurate calculation results, real force conditions, and reasonable judgment methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The best implementation mode of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0038] A method for determining the stiffness and stability of a nacelle cover of the present invention comprises the following steps:

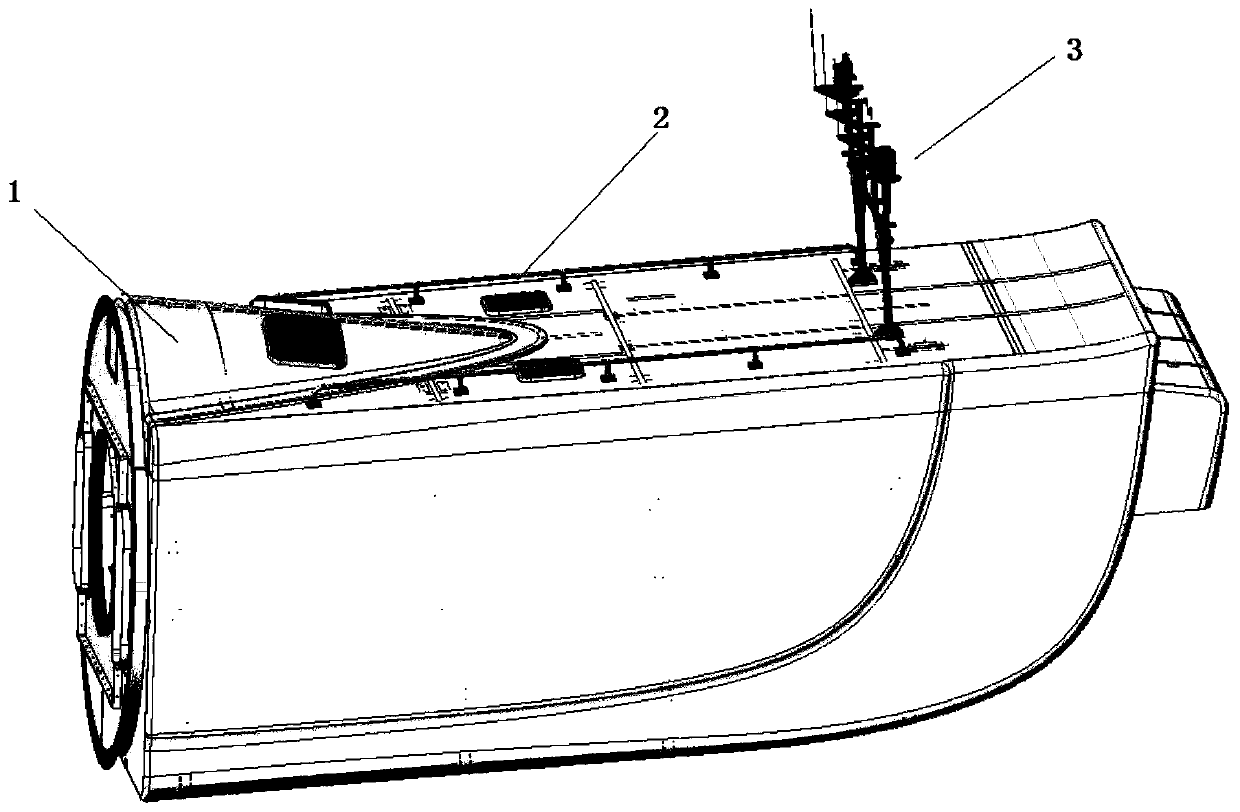

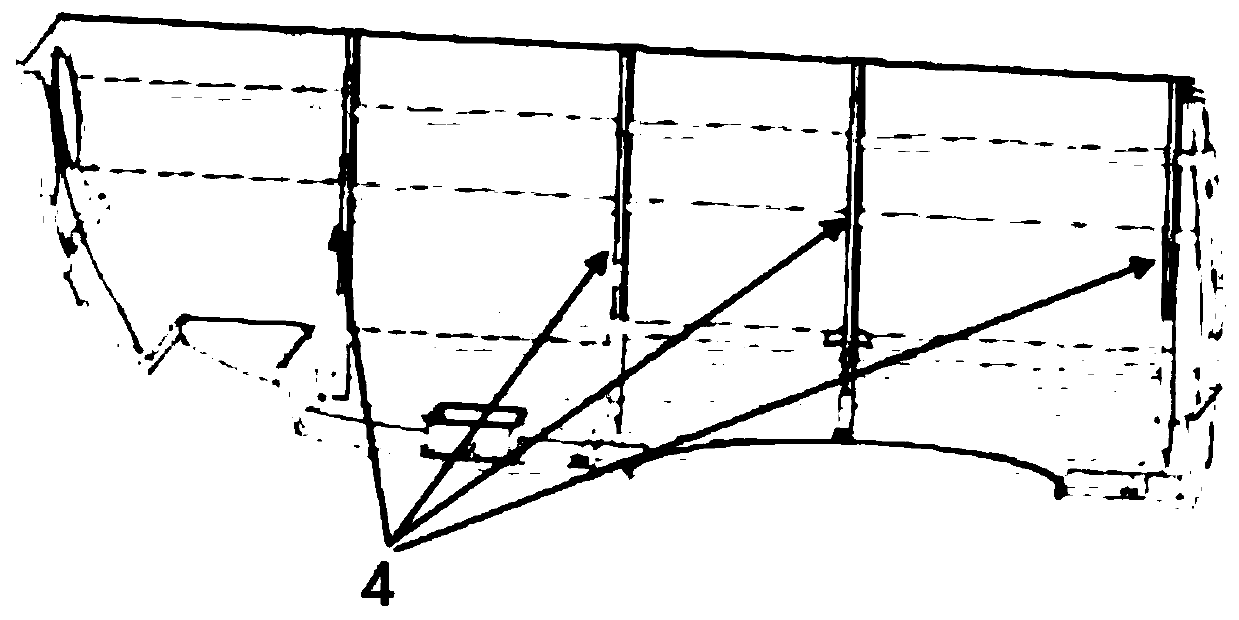

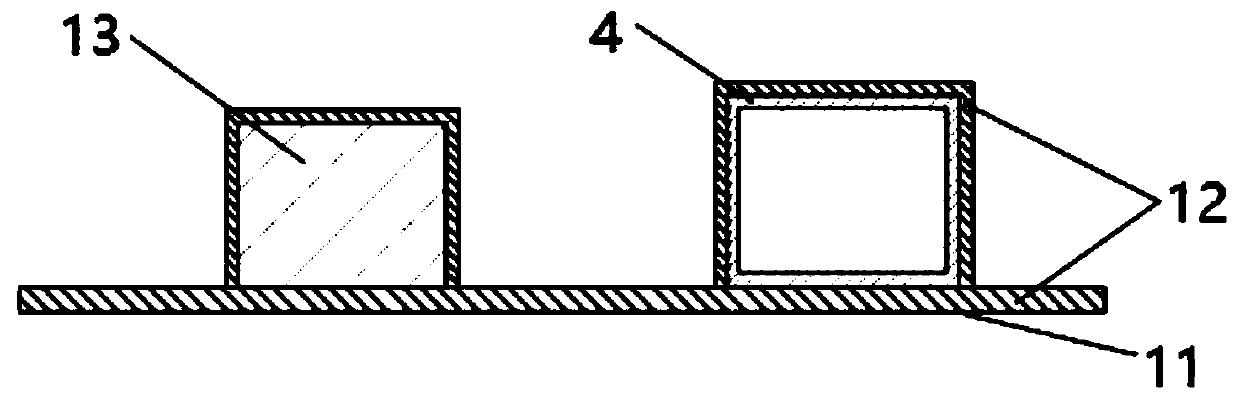

[0039] 1. Establish the geometric model of the wind turbine nacelle cover, such as figure 1 , 2 As shown, it includes a cover shell 1 made of fiberglass composite material, a steel structure 4 inside the cover shell, a guardrail 2 and an anemometer 3 fixed on the top of the cover shell, wherein the wind turbine nacelle cover is integrally fixed on the base, and the cover body The shell 1 and the steel structure 4 are bonded to each other.

[0040] 2. Properly simplify the geometric model of the wind turbine nacelle cover, delete small threaded holes and chamfers; import the three-dimensional geometric model of the wind turbine nacelle cover into the finite element analysis software ANSYS Workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com