System and method applicable to uranium hexafluoride liquefaction and sample distribution

A uranium hexafluoride and sample technology, which is applied in the system field of UF6 liquefaction and sample separation, can solve the problems of low sample separation efficiency and low stability, improve sample separation efficiency, save sample separation time, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A system and method suitable for liquefaction and sampling of UF6 according to the present invention will be described in detail below with reference to the drawings and examples.

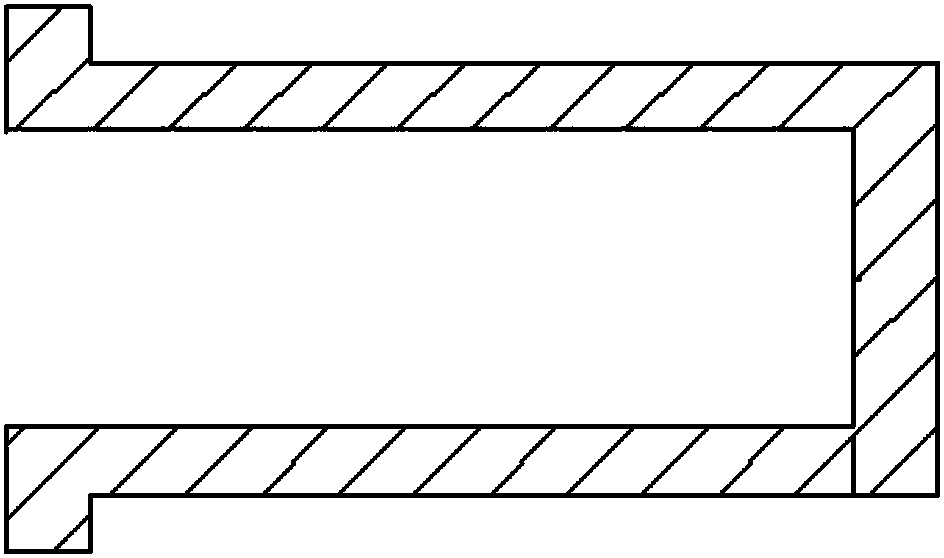

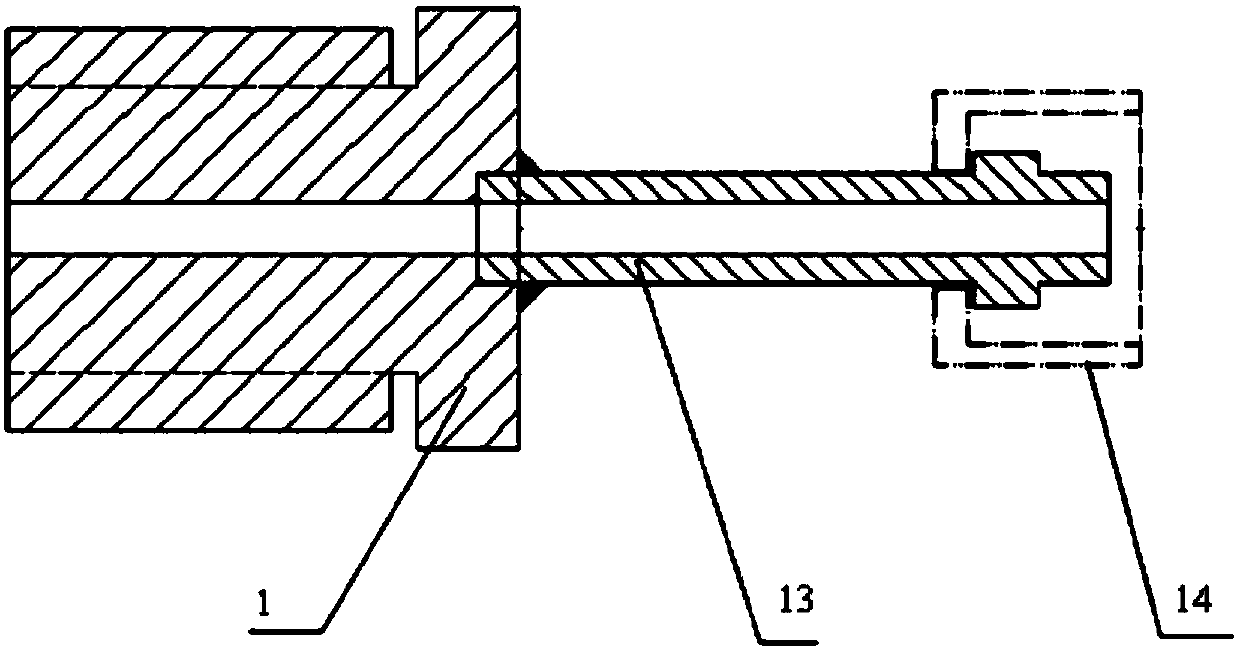

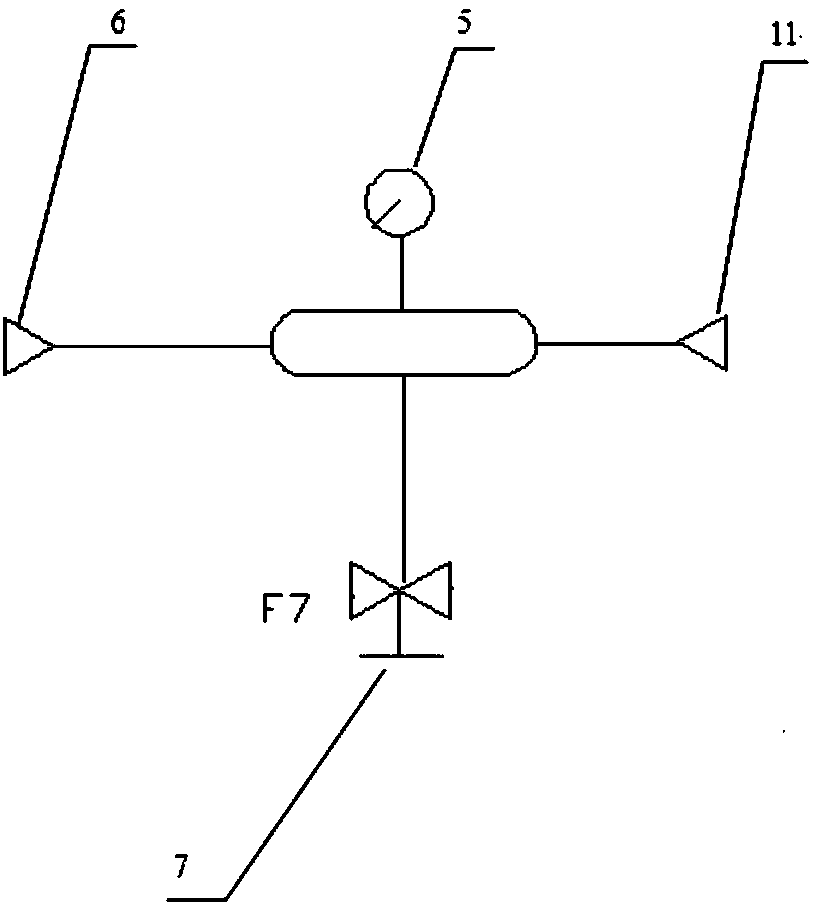

[0032] Such as Figure 8 As shown, a system of the present invention suitable for liquefaction and sample separation of UF6 includes a sample storage channel, a pressure gauge, an oven, a channel residual sample collection container (1 liter container), Φ3 valve F7, Φ3 valve F8 and Φ3 Bottom flange adapter. The pressure gauge, oven, channel residual sample collection container (1 liter container), and Φ3 valve F7 are respectively connected to different ports of the sample storage channel, and Φ3 valve F7 passes through Figure 4 The elbow connector shown is connected to the Φ3 valve bottom flange transition head, the Φ3 valve bottom flange transition head is installed with the Φ3 valve F8, and the Φ3 valve F8 and the two sample sampling ports pass through respectively Image 6 The sampling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com