Test device and test method for fatigue life of bearing with ultra-low temperature and high DN value

A test device and fatigue life technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of turbine pump damage, high test cost, inability to assess the impact of bearing life, etc., to provide damping effect, high reliability, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

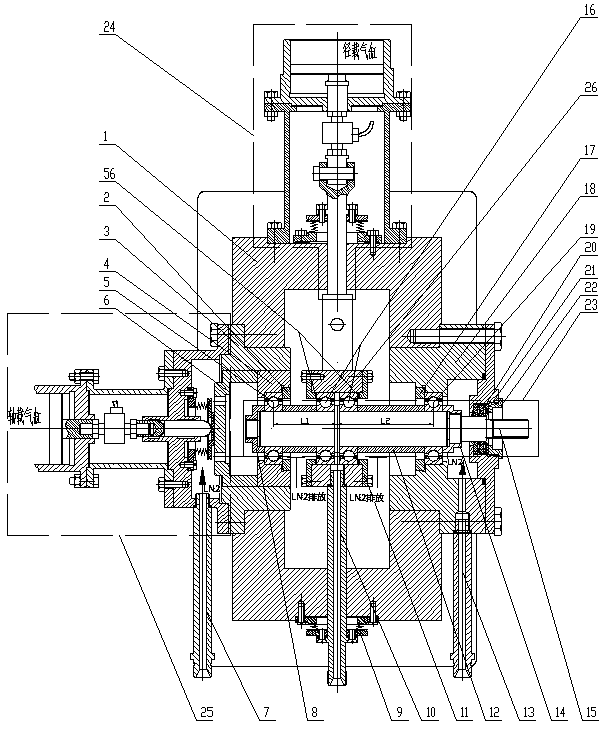

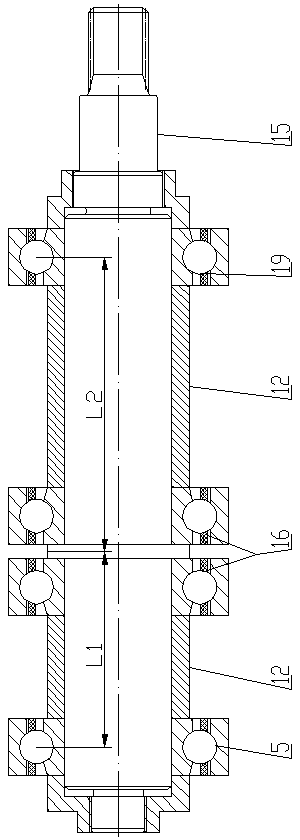

[0044] as attached figure 1 , 2 As shown, the embodiment of the present invention provides a test device for the fatigue life of ultra-low temperature and high DN value bearings. The test device consists of an axial flexible loading device 25, a radial flexible loading device 24, a device housing 1, a test rotor 23 and The cup seal assembly is composed.

[0045] Since the test device is assembled and centered at normal temperature, the entire test device will shrink under the low temperature medium environment, that is, the center height of the test device will settle. The driving parts that drive the test device to rotate will thermally expand as the speed increases, and the thermal expansion and settlement values are different under different speeds and vibration levels. The occurrence of misalignment will impose a dynamic load on the test device, resulting in a decrease in the reliability of the test device. In order to reduce the dynamic load of the test device as muc...

Embodiment 2

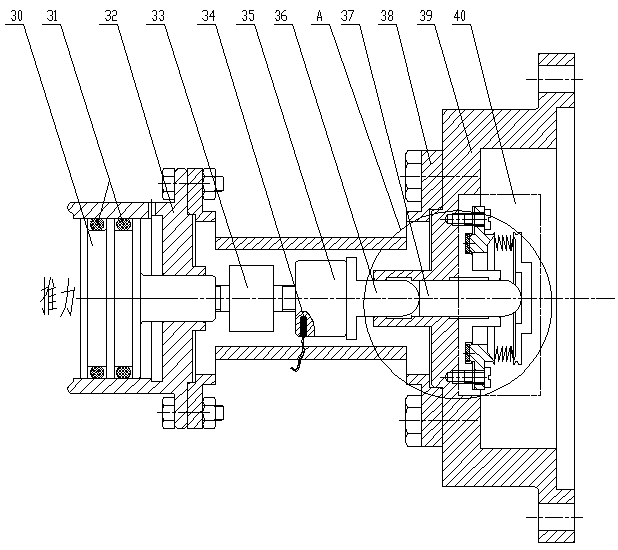

[0050] as attached Figure 3-5 As shown, the embodiment of the present invention provides a test device for the fatigue life of ultra-low temperature and high DN value bearings. The axial piston 30, the O-ring 31 and the axial piston barrel 32 together form an axially loaded cylinder. The axially loaded cylinder generates thrust under the action of compressed air, which is transmitted to the axial adapter block 35 through the axial force sensor 33, and the outer layer of the axial adapter block 35 is wrapped with a heating belt to protect the axial force sensor 33 in a normal temperature environment , Pt100 thermal resistance one 34 is used to monitor the temperature of the axial adapter block 35 in real time. The axial transfer block 35 transmits the axial force to the dowel rod 36, and the dowel rod 36 is in point-to-surface contact with the transition push rod 37 to adjust the axial force. The axial force is finally transmitted to the axial bellows sealing assembly 40, and...

Embodiment 3

[0052] as attached Image 6 , 7 As shown, the embodiment of the present invention provides a test device for fatigue life of ultra-low temperature and high DN value bearings. The radial piston 44 and the radial piston barrel 45 form a radially loaded cylinder. The radial loading cylinder generates a pulling force on the radial force sensor, and the sensor transmits the pulling force to the radial transfer block 49, and the outer layer of the radial transfer block 49 is wrapped with a heating tape to protect the radial force sensor 47 in a normal temperature environment, Pt100 thermal The second resistor 48 is used to monitor the temperature of the radial adapter block 49 in real time. The radial adapter block 49 and the tie rod joint 50 are threadedly connected to transmit the pulling force. The pull rod joint 50 transmits the pulling force to the radial pull rod 52 through the radial pin 51, and the radial bellows sealing assembly 9 plays the role of sealing and displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com