Intelligent assembly and verification integrated machine for water meter

An all-in-one machine and water meter technology, applied in the field of water meter calibration, can solve problems that affect customer experience and corporate reputation, long water meter calibration time, and defective products flow into the market, etc., to achieve large profit margins, reduce labor costs, and reduce production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

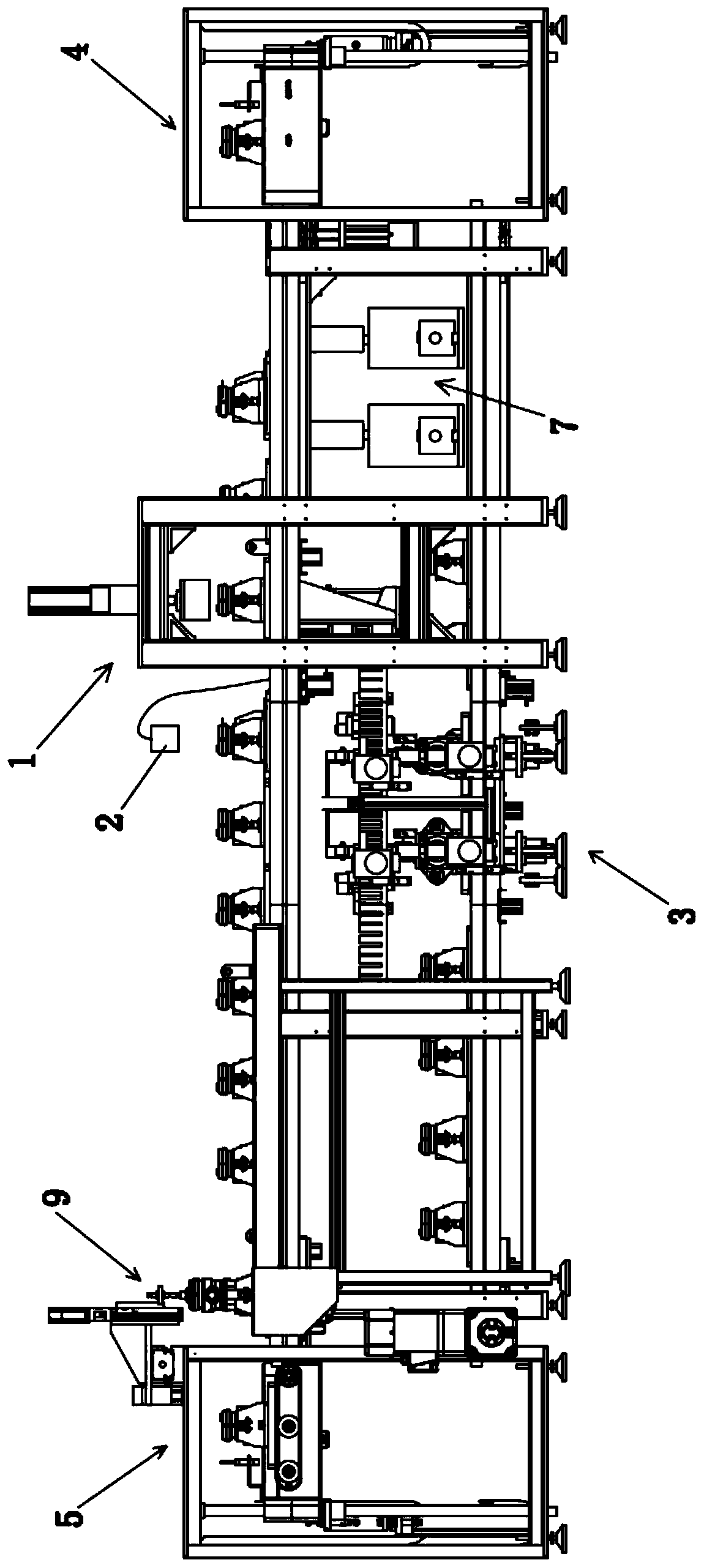

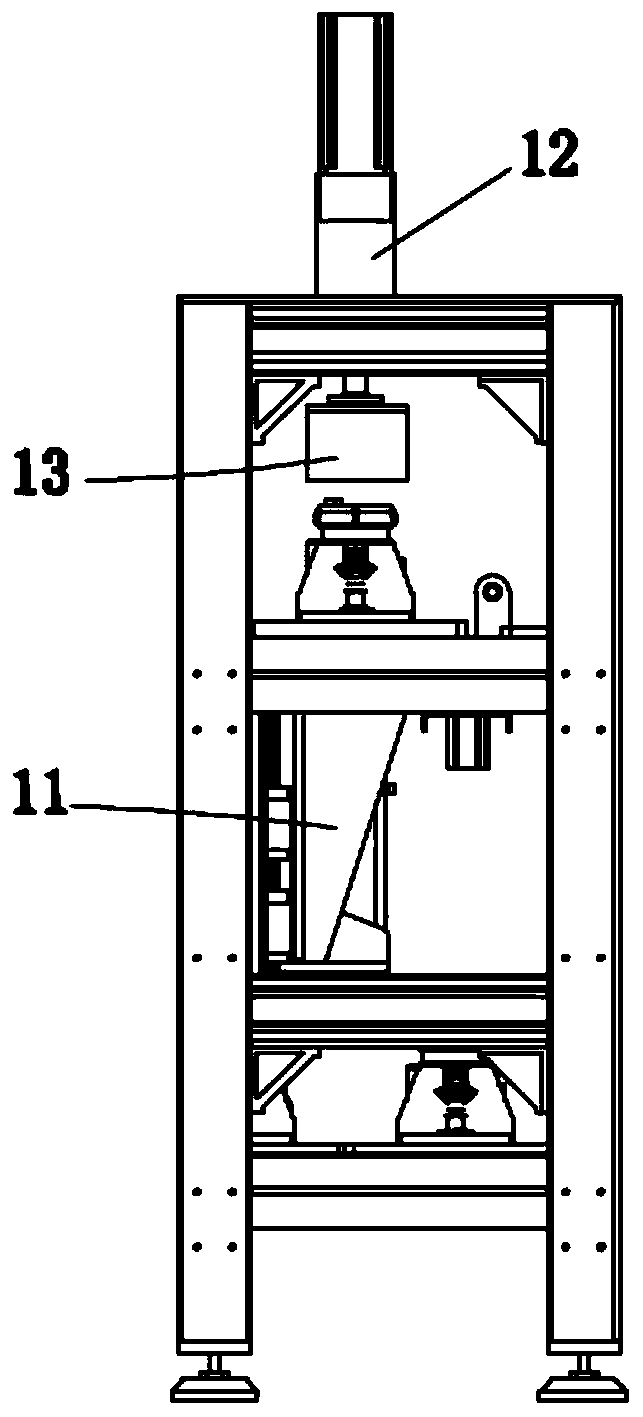

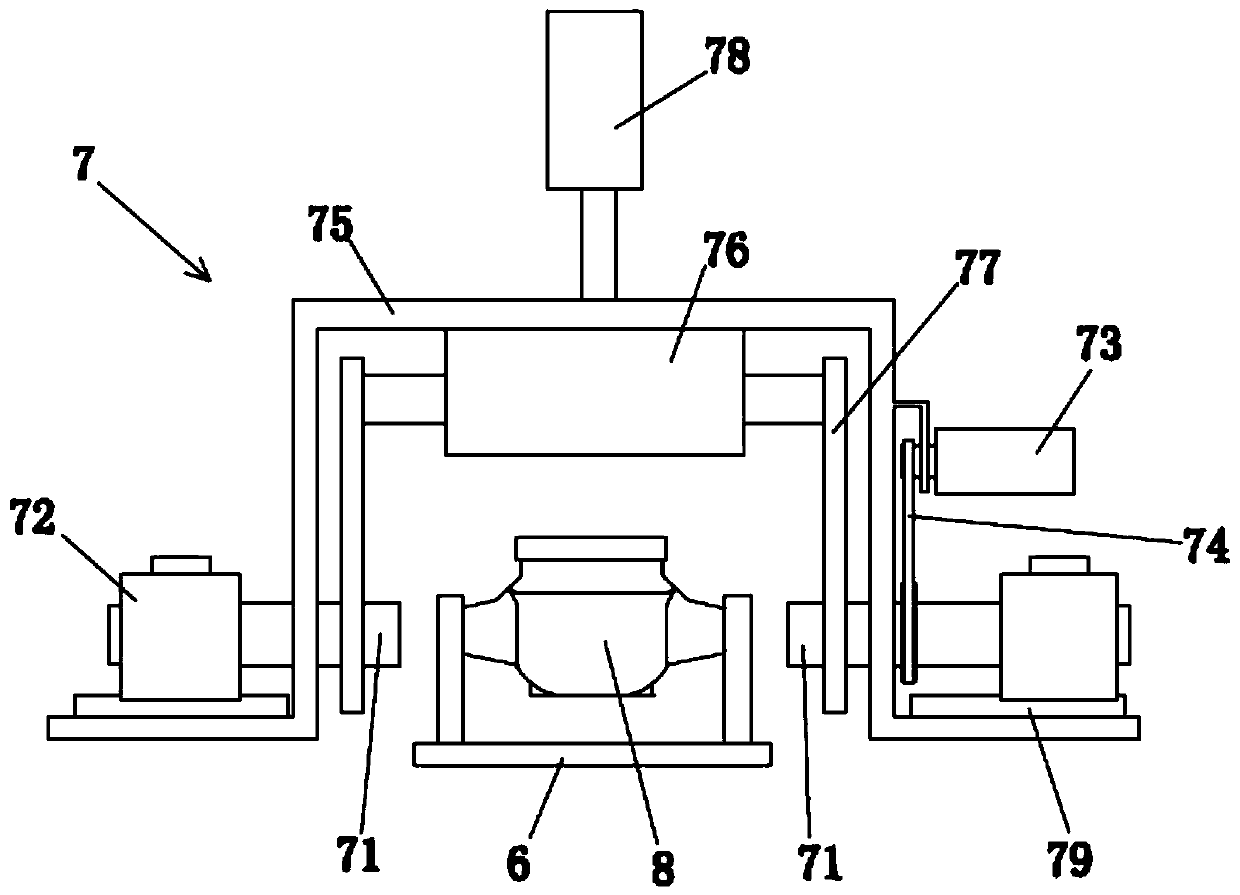

[0035] The specific embodiment of the present invention is as Figure 1 to Figure 8 As shown, a water meter intelligent installation and calibration machine includes a machine platform and a water meter conveyor line mechanism. The machine platform is sequentially equipped with a water meter scanning code station, a cover station, and a vacuum water injection station along the conveying direction of the conveyor line mechanism. station, checking station and sorting station. The code scanning station is provided with a code scanning device 2 . The upper cover station is provided with an upper cover device 1 capable of locking the water meter cover. The vacuum water injection station is provided with a vacuum water injection device 7 . The calibration station is provided with a calibration device 3 . The sorting station is provided with a sorting mechanism 9. In this embodiment, the transmission line mechanism is a chain transmission mechanism, which includes a chain, a spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com