Vacuum drying box

A technology of vacuum drying oven and drying oven, which is used in drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problem that the box body cannot be kept in a good sealing state, the edge of the stainless steel box body is rusted, and the sealing strip is corroded. Softening and other problems, to achieve good thermal insulation effect, avoid corrosion, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better explain the present invention and facilitate understanding, the following describes the present invention in detail through specific embodiments in conjunction with the accompanying drawings.

[0040] It should be noted that the "inside" in the present invention refers to the side facing the inside of the drying box, and the "outside" refers to the side facing the outside of the drying box.

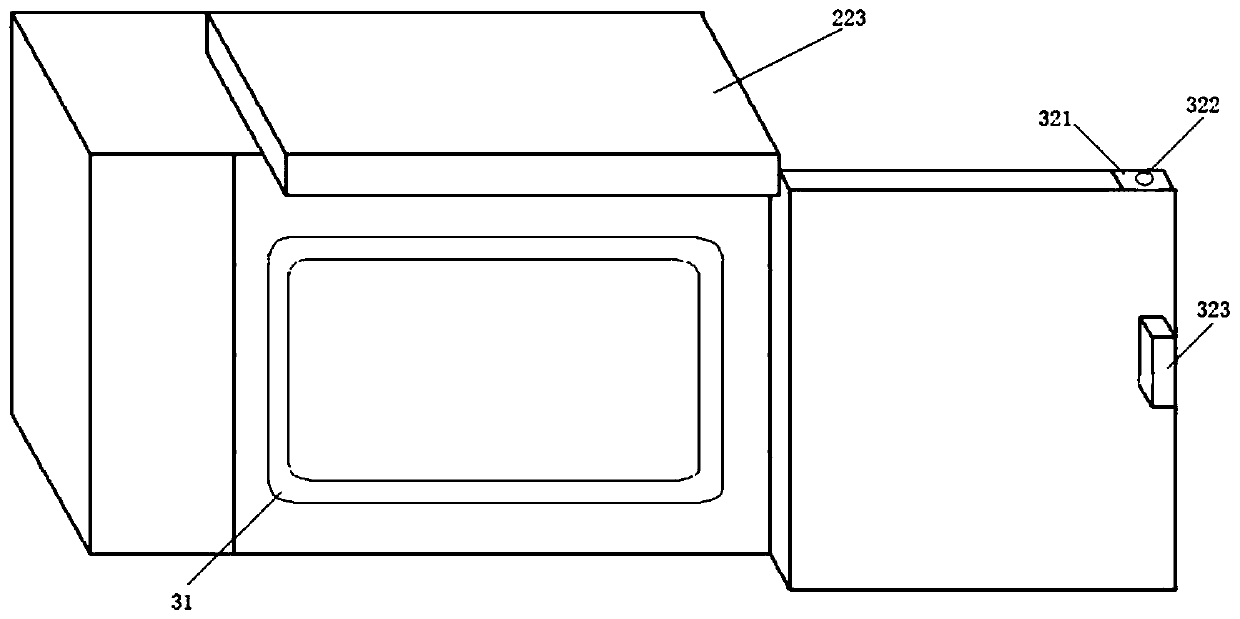

[0041] The invention provides a vacuum drying oven, such as figure 1 with 2 As shown, it includes a base 1, a box body 2 with side openings, and an openable cover body 3 for closing the side openings. The box body 2 is fixedly installed on the base 1 and the cover body 3 and the box body 2 are rotatably connected.

[0042] Box

[0043] The box body 2 includes a drying box 21 and a storage box 22.

[0044] The drying box 21 is set as a box structure with an opening, and the drying box 21 is fixedly installed on the base 1 so that the opening of the drying box faces one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com