Manufacturing process of reservoir

A manufacturing process and a technology for a liquid reservoir, which is applied in the field of liquid storage manufacturing technology, can solve the problems of poor sealing, high process cost, and difficult maintenance at the connection between the cylinder body and the end cover, and achieves that it is not easy to separate, strengthen and reinforce effect, the effect of reducing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Such as Figure 1 to Figure 7 Shown, be the reservoir manufacturing process of the present invention, comprise the steps:

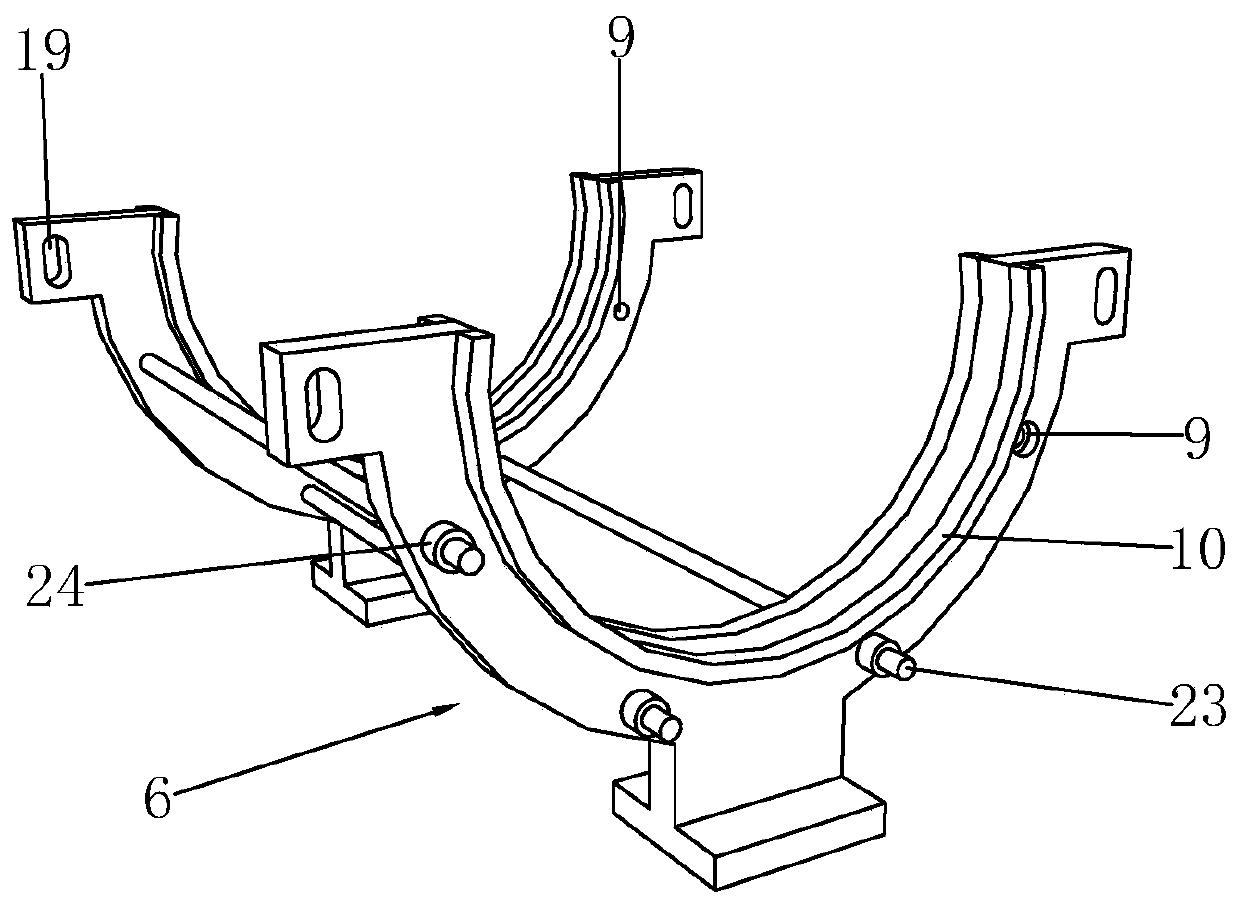

[0039] (a) The basic components are in place: First, the cylinder body 1, two end caps 2, mounting ring 3, fixing ring 4, gland 5 and half-arc bracket 6 are obtained through mold processing. The half-arc bracket 6 includes a support base 7 and a half-arc The arc supporting plate 8 and the semi-arc supporting plate 8 correspond to the cylinder body 1, and the semi-arc supporting plate 8 is arranged on the support base 7, which is an integrally formed structure with high strength, simple structure, low manufacturing process requirements, and can be mass-produced. There are fixed counterbores 9 distributed around the semi-arc supporting plate 8. The setting of the fixed counterbores 9 is convenient for piercing rods. Multiple semi-arc brackets 6 can be assembled into one body to form a supporting base 7 to enhance the support for the cylinder 1. effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com