Double-valve-body drain valve and assembly method thereof

A trap and valve body technology, which is applied in the direction of the valve's device for absorbing fluid energy, valve device, valve element and valve seat, etc., can solve the problem of increasing installation difficulty, making the trap unusable, and can only be used Install according to the specified direction to achieve the effect of preventing water flow turbulence, good sealing performance and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

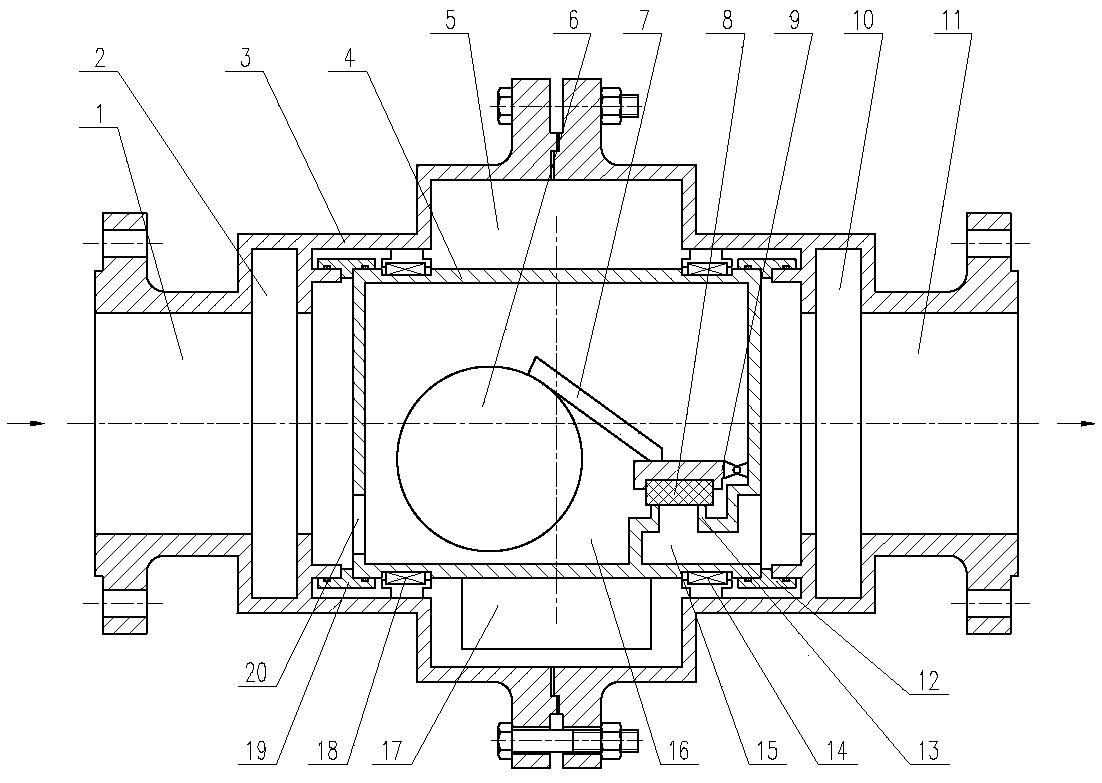

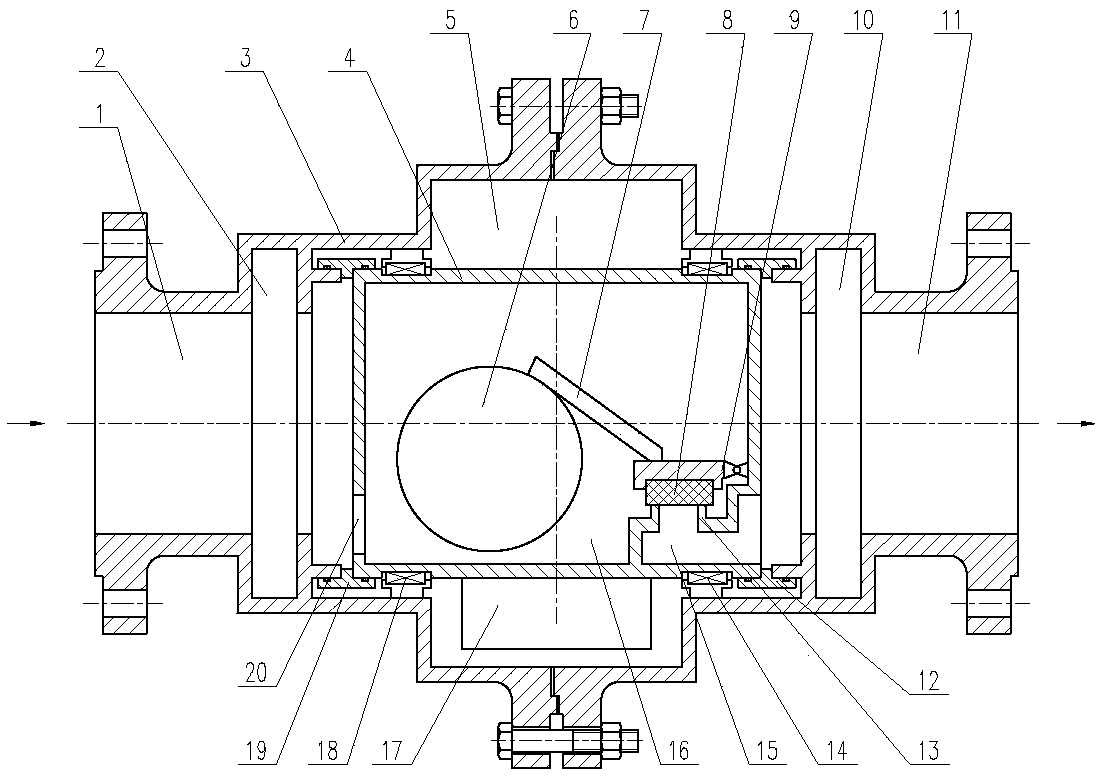

[0020] according to figure 1 It can be seen that this kind of double valve body steam trap comprises: a float 6, a connecting rod 7, a valve disc 8 and a valve seat 13, the upper end surface of the valve seat 13 is provided with a valve seat sealing surface, and the lower end surface of the valve disc 8 is provided with a The sealing surface of the valve seat cooperates to form a sealed valve disc sealing surface. One end of the connecting rod 7 is connected to the valve disc 8, and the other end of the connecting rod 7 is connected to the floating ball 6. It also includes an outer valve body 3 and an inner valve body 4. The outer valve body 3 is provided with an inlet channel 1, an inlet anti-scouring groove 2, an outer valve body middle chamber 5, an outlet anti-scouring groove 10, and an outlet channel 11. The inlet anti-scouring groove 2 is an arc-shaped groove structure, which is arranged at the inlet Between the channel 1 and the inner cavity 5 of the outer valve body, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com